Cloudflare Ray ID: 63aa0a91ad7615e4 • Your IP: 195.64.208.251 • Performance & security by Cloudflare

When choosing a spinning reel for a spinning rod, you should pay attention to the presence of a spare spool in the kit. For example, I have thin braid wound on one spool, and monofilament on the other. I won’t talk about the advantages of braid over fishing line and vice versa here. Let me just say that I mostly use braid, but when fishing for pike, sometimes I can use a spool with fishing line.

Number of bearings

The choice of a spinning reel for beginners is often based on some unimportant parameters, such as the number of bearings. Yes, undoubtedly the number of bearings in a reel is an important parameter, but it is also worth remembering that Chinese manufacturers abuse this parameter for marketing purposes. You can often find reels with 7-8 bearings on the shelves, but for some reason such a reel ultimately loses to the entry-level Japanese reel with 4 bearings.

So which reel is best for spinning? With 8 or 4 bearings? There is no clear answer to this question. First of all, you need to hold the reel in your hands and check it for any play in the handle and other parts. The product should have a smooth and “velvety” stroke, which is so important in spinning fishing.

The smaller the dimension value, the lighter the tackle and bait can be used with this reel. Here is an approximate table of correspondence between the standard size of the spool and the weight of the equipment used:

Characteristics of spinning reels

Inertia-free is a technically complex mechanism with a lot of technical characteristics, each of which affects the capabilities and price of the reel. Let's take a closer look at them.

Gear ratio

The number of rotations of the rotor per revolution of the reel handle is called the gear ratio - the higher the gear ratio, the more line the reel picks up per revolution. The average gear ratio is 5:1, values less than this are typical for power reels, and more for high-speed and longcast ones.

- Low gear ratios - the traction characteristics increase, the loads on the reel are distributed more evenly, and it becomes a little easier to pull out really large fish. Low gear ratios are suitable for fishing with crankbaits, jerkbaits and heavy jigs.

High gear ratios - you can reel in large volumes of line faster and fish a larger area faster. High-speed reels are more sensitive and work well with most baits except the heaviest ones - excessive loads can destroy them. Fast reels are well suited for twitching; it is more convenient to choose loosening cord with a high gear ratio.

Medium gear ratios - if you have no idea what exactly you will use the reel for, then we recommend that you choose universal reels with a gear ratio from 5:1 to 6:1. Such reels are suitable for most types of fishing and animation of all baits.

Coil clutch

The friction brake in reels is of fundamental importance - it does not allow the fish to escape during strong jerks, giving up the line under load, and protects the tackle from breaking.

The clutch can be front, rear and also double, but for spinning fishing only the first two are used.

Regardless of the type of clutch, it is necessary to release it after fishing until the spool rotates freely - this will significantly extend the life of the reel.

Coil size

The size of the spool directly affects the amount and cross-section of the fishing line, and indirectly affects the casting distance. In spinning fishing, sizes from 1000 to 4000 are mainly used, but in some rare cases, for example for sea fishing, these can be reels with a spool of 5000-7000.

The smaller the dimension value, the lighter the tackle and bait can be used with this reel. Here is an approximate table of correspondence between the standard size of the spool and the weight of the equipment used:

For beginner spinning players, we recommend choosing reels from 1000 to 2500 for light and ultra-light rods, 3000-4000 for the middle class, and 4000+ for sea spinning fishing or heavy jigs - such combinations of rod size and class allow you to achieve an optimal balance ratio without overloading the equipment elements and do not tire your hand with frequent casts.

Bearings

The number of bearings is almost the first characteristic that different manufacturers trump. But is it really that important?

There is a myth that the more bearings in a reel’s design, the better it should work, but in fact this only overcomplicates the design, reduces its reliability and makes it more sensitive to contamination.

For excellent smooth running and uniform unloading of the mechanism, 4-6 bearings are sufficient; most reels are equipped with exactly this number. Marking +1 means the presence of a roller bearing for the overrunning clutch of the reverse stopper.

Secondary characteristics when choosing a reel

There are also characteristics that affect usability to a greater extent, but they are still quite important:

Cloudflare Ray ID: 63aa0ab3ee05005d • Your IP: 195.64.208.251 • Performance & security by Cloudflare

Inertial reels are a thing of the past for most fishermen due to the complexity of the process: the reel unwinds even when the bait is at the desired point. If you don’t want to unravel the line, you need to manually stop the reel. But there is also a plus in inertia: the tackle is more sensitive than others, because by fixing the line with his fingers, the fisherman immediately feels the bite.

Spinning reel handles

- VK

We can say that the handle is not the first part of the reel, but not the second either. By rotating the handle, we set the entire reel mechanism in motion, forcing the main gear to rotate, and it initiates the movement of other gears responsible for rotating the rotor and feeding the spool back and forth for uniform laying of the fishing line.

Using tactile sensations when rotating the handle, we can diagnose the condition of the internal mechanism of the reel: is it lubricated, are there large gaps between the parts of the reel mechanism, what is the condition of the bearings, etc.

For a substantive conversation about this important part of a spinning reel, we present a general diagram of the handle with the names of its parts (photo 1).

The most commonly used handle designs can be divided into three types according to the method of folding them for transportation: 1st type - the handle folds when the clamping screw is not completely unscrewed (photo 1); 2nd type - the handle folds when you press a special button in node 4 (photo 2)

3rd type - the axis of the handle is a screw, and the handle is folded by unscrewing it from the threaded hole in the axis of the drive gear with the reel rotor clamped with the palm of your hand (photo 3).

The first domestically produced spinning reels were equipped with handles of the third type. An interesting fact is that the power reel models of the leading fishing tackle manufacturer Shimano are also equipped with handles of this system. The most common part of the handle that fails is the axis of the fungus. This is especially true for handles in which the plastic fungus rotates directly on a metal axis, and the outer hole is not closed with a plug. Therefore, the axis of the fungus is most susceptible to contamination.

Particles of dirt and grains of sand are hard formations that are easily pressed into the plastic of the fungus, forming an abrasive surface, very quickly grinding down the axle.

The simplest preventative procedure for such handles is to frequently wash and lubricate this unit with liquid oil; it would also be a good idea to close the hole in the fungus with a plug made of rubber, foam rubber or sealant (photo 4).

Recently, designers have taken into account this unpleasant feature of the metal-plastic pair, and handles have appeared that do not have plastic fungi. These pens always have a plug, metal rubs against metal, and some even have two ball bearings. But it is still necessary to lubricate them at least once a month.

Also, the push-button unit for folding the handle into the transport position often fails. The reason for this is offensively banal. When folding such a handle, we must press the button, and when we move the handle to the working position, we simply move it to the side, and the spring-loaded button clicks into a locking position. This procedure, repeated many times, leads to the erasure of the rectangular edges in the locking mechanism of the unit, and it crumbles into its component parts. After this, the only way out is to block the unit, and the handle no longer folds. And all that was needed was to press the locking button when unfolding the handle into the working position and release it when the handle took the working position.

Quite often, anglers break the clamping screw (part 6 in photo 1) while trying to tighten it in order to remove the longitudinal play in the handle that occurs during the operation of the reel. This play is eliminated by a completely different method, and tightening the clamping screw only leads to its breakage.

Why are expensive power reels equipped with a 3rd type handle. To do this, consider the interface of the handle axis with the drive gear of the reel. Typically the handle axis is a hexagon or tetrahedron. Accordingly, the main gear axis has a hexagonal or quadrangular hole. Whether we like it or not, the dimensions of the hole are slightly larger than the corresponding dimensions of the axis. This is the reason for the play of the handle, which is clearly felt when the handle rocks back and forth if you hold the reel rotor with your palm. During the operation of reels with handles of the 1st and 2nd types, this backlash only increases. This drawback was not so noticeable in reels of the old design with a ratcheting mechanism for the reverse stop, when the handle worked back 15 degrees. After they began to use an instantaneous reverse stop in reels, this play is felt more strongly, especially when the fish bites. Handles of the third type are free of this drawback - the pairing of the handle with the drive gear is completely free of backlash. It is clear that power class reels designed for heavy loads are equipped only with such handles.

Using the pen, you can diagnose the internal condition of the spinning reel mechanism. Most often, spinners use a reel without caring at all about the quality of its work - it spins, that’s good. It’s only when the reel starts to jam that they start to get worried. Handles of inertia-free reels But the approaching premature “old age” of the reel could have been noticed much earlier and, by taking measures, extending the life of its normal operation, the key to high-quality operation of the internal mechanism of the reel lies not only in timely lubrication, but also in the precise mating of the teeth of the drive and rotor gears. The gap between the gear teeth should be minimal. How to determine that this gap has already increased and some adjustment is required.

Place the reel handle in the working position. Grasp the handle with your fingers at the base near the reel body (photo 5) and move it back and forth along the axis of the handle.

You will feel some play. It should be small (0.1-0.2 mm). This play determines the gap between the teeth of the drive gear and the rotor gear. If it is larger, then it is necessary to reduce it by selecting a fitting washer (or several), which is placed between the bearing and the drive gear of the coil. I note that any reel has these washers, that is, during manufacturing such an adjustment was made, but during operation the gap increases and it needs to be adjusted by installing additional washers.

Related articles:

Meat-colored fish

Classification of Daiwa spinning reels

Kiev Reservoir

Fish migration

Coil weight

And, again, this parameter is closely related to the previous two. The smallest spinning reel in terms of size will, accordingly, weigh the least.

There is no need to choose the lightest weight tackle: powerful mechanisms are almost always quite massive, as they consist of metal parts, which leads to the weight of the rod and the structure as a whole.

The lightest are plastic models, which are chosen for ultralight fishing. Among their disadvantages is fragility. Considering that even the smallest notch will shorten the casting distance by a third, experienced fishermen choose metal, heavier variations. The line glides well on such reels, making it much easier to cast bait.

As an alternative to light weight and high quality, branded companies offer products made from aluminum, titanium, and various durable polymer alloys - this significantly reduces the final weight of the product and does not interfere with the comfort of the spinner.

The use of braided cords and jerking methods of wiring impose rather stringent requirements on the quality of winding the cord onto the spool. Without going into detail, the installation should be as smooth as possible without bumps or dips. The quality of the winding can hardly be assessed in advance. But it is useful to ask on any active fishing forum about the reel you are planning to choose.

1. Price category of the reel . If you are a “weekend” fisherman and there is no serious load on the gear, then you can opt for an inertia-free fishing rod that costs 2,000 – 4,000 rubles. For example, the Stinger ForceAge XW series. For more frequent and intensive use, a model from 5,000 to 10,000 is better suited. Legalis-12 2500 from Daiwa belongs to this price category.

2. Size of the spinning reel . Depends on the type of fishing. The higher the value, the heavier the class: 1000 is ultralight, 2500 is medium-light and medium, 4000 is medium-heavy, etc. Pay attention to the line capacity of the spool. The universal size for a beginner is 2500. It allows you to cover the maximum range of baits and weights.

3 . Reel weight . Depends on the type of fishing. It is selected according to the principle “the less the better”, but without loss of strength. Must match the weight of the rod.

4 . Gear ratio or reduction . The optimal average for a beginner is 5.0:1 (with slight deviations +/-).

5 . The friction brake of a spinning reel is front, it handles jerks better.

6 . Laying the line should be as even as possible. It is better to rely on the experience of other anglers in using a particular reel or expert opinion.

7 . Spare spool . Convenient for using fishing line (cords) of different diameters. Its presence in the package does not affect the service life of the reel, but as a rule, it increases the cost.

8 . Reel brand . Budget category: Stinger or Select. Higher price segment - Daiwa and Shimano.

9. Indexes and abbreviations.

Both beginners and even pros when choosing a spinning reel are faced with various abbreviations. Since there is no single classification, each brand may have its own abbreviations. We offer a cheat sheet on possible indexes:

The most common ones found among different manufacturers are:

TOP 10 tips for choosing a spinning reel

Spinning reels: line lay, spool

- VK

The spinning reel (hereinafter simply reel) has become widespread among fishermen due to its versatility, functionality and ease of use. Let's look at the main functions of the reel: line laying, braking function, reverse blocking, gear ratio. How to choose a reel and properly care for it. Content:

- LAYING THE LINE

- BRAKING FUNCTION. FRICTION BRAKE

- BLOCKING REVERSE. ANTI-REVERSE

- SPOOL

- GEAR RATIO

- COIL SELECTION

- REEL CARE

LAYING THE LINE

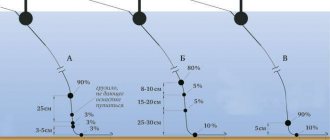

The forward-backward spool feed mechanism and the line guide installed on the reel rotor are responsible for laying the line in the reel. There are two types of spool feed mechanisms: an endless screw (photo 1), which provides the best line winding, and a “locomotive” type rocker system (photo 2).

photo 1

photo 2

The line laying device consists of a line laying arc, a mechanism for returning the arc to the working position and a roller. For a long time, the elastic element of arc return was a spring made of several turns of wire with long tangent ends (photo 3).

photo 3

When cocking the line-laying arc, the spring worked to twist the coils, which led to significant stress in the hardened wire and quite frequent breakages. I had to take spare springs with me when fishing. Then, first in expensive and then in cheap coils, “long-lived” multi-turn springs appeared, working not to twist the coil, but to compress the interturn distance of the spring (photo 4). Some coils provide fixation of the cocked arc, preventing its spontaneous release.

photo 4

The latest reel models use a system that slows down the reel rotor when the line arc is retracted. This system completely eliminates unauthorized release of the arc during casting.

Automatic reset of the line laying arc occurs when the handle rotates when the rotor collides with the eccentric in the reel body. Although this function is provided by the design, it should be used only in emergency cases, since the consequences of shock loads lead to premature failure of this unit. Most experienced anglers move the line arc to the hand winding position.

The line-laying arc is usually an elastic stainless steel wire bent in a special way. Violation of the bending shape leads to its incomplete folding, and therefore to spontaneous closure when casting. It happens that after closing the arc, the line remains on it, without getting onto the line roller, which gradually leads to damage to the arc. As a rule, this defect occurs when the arc is deformed, so you need to handle this part of the coil very carefully.

The line roller is in direct contact with the fishing line, so the quality of its surface and ease of rotation during winding are a guarantee that the fishing line will not be damaged. Typically the roller is made of bronze, plated with hard chrome and polished. In expensive reels, the roller must have a miniature ball bearing and a hard, wear-resistant coating made of golden titanium nitride. The first sign of trouble with the roller is uneven wear of the coating from its surface and cuts appearing in it. This means that the roller has stopped rotating or rotates with difficulty. Therefore, you need to very carefully monitor the condition of the line roller, lubricating it at least once every 2-3 fishing trips.

BRAKING FUNCTION. FRICTION BRAKE

The reel's braking system allows you to land fish without the risk of breaking the line. Jerks of the fish, the force of which exceeds the value of the set braking force, leads to automatic slipping of the spool and the line coming off.

The friction brake can be located directly in the reel spool (front brake) or located at the rear of the reel body (rear brake). Both systems have their advantages and disadvantages. The advantages of the rear brake are ease of adjustment when playing fish (the ability to quickly replace the spool). Disadvantages include coarser tuning and less braking force (compared to the front brake).

The front location of the friction brake reduces the size of the reel and makes the brake more finely adjustable. Structurally, the brake of any reel is a set of alternating steel and non-metallic disks, compressed when the clamping screw is tightened. Do not allow sand to get between the discs, and also do not lubricate them excessively.

BLOCKING REVERSE. ANTI-REVERSE

This system blocks the reel rotor, preventing it from spinning in the direction opposite to winding. During fishing, the reverse stop switch must be turned on, which allows you to free one hand at the final stage of landing the fish to grab the fish with your hand or in the landing net.

Today, the most advanced system is the infinite antireverse or instantaneous stopper. This system turned out to be so successful that it is gradually replacing all others and is already used in relatively inexpensive reels. Structurally, it is a roller bearing, the rollers of which can be forced to move along the radius of the bearing. When the stopper is engaged, the rollers move towards the overrunning clutch located on the rotor gear, blocking its backward movement. When turned off, the rollers move away from the overrunning clutch, allowing the rotor to rotate freely in both directions.

SPOOL

Reel spools are made of durable plastic or metal. Reels are also produced whose spools are made of carbon fiber and have a metal side. One of the best options is a metal spool with a titanium nitride coated carbide front. When using a reel, you need to pay attention to the quality of the surface of the spool side, which determines the flight range of the bait and the safety of the fishing line surface. Any scratches, burrs or depressions that occur must be removed with fine sandpaper and polished.

There is an opinion that plastic spools cannot be used when fishing with braided line. However, if you clean and polish the seams formed when casting the spool, the spool becomes quite suitable for braided fishing line.

The spool usually holds more than 100 m of fishing line needed for fishing. Therefore, to fill the excess volume, inexpensive monofilament fishing line is wound under the main line. In order for the line to come off the spool when casting without tangling and significant resistance, the spool must be filled with line, not reaching 2-3 mm to the upper edge of the front edge.

Daiwa has developed an ABS (anti backlash system) spool. This spool has an increased diameter and is made in the form of a truncated cone facing the base. This design allows you to avoid involuntary dropping of line loops at the time of casting, and also increases the casting distance. Therefore, the abbreviation ABS among American professional fishermen began to be read as “advanced ballistic system,” which translated from English means “advanced ballistic system” (photo).

Shimano has proposed a simpler solution to this same problem and equips its reels with a set of shims. The fisherman can choose the type of winding at his discretion - cylindrical, with a slope towards the front or rear side of the spool.

GEAR RATIO

The gear ratio is the number of revolutions of the reel rotor per revolution of the handle. Numerically, it is equal to the ratio of the number of teeth of the drive gear to the number of teeth of the rotor gear. Powerful traction reels have a small gear ratio - from 3.6:1 to 4.6:1. A gear ratio close to 5:1 is considered the most universal.

Higher-speed reels with a gear ratio of 6:1 - 7:1 are used in float fishing on match rods. The high gear ratio increases the tightness of the line winding, making it easier to fish with such rods. The choice of a reel with a certain gear ratio is determined by the size of the expected trophies and fishing conditions. The larger the fish that can be caught and the more severe the fishing conditions, the smaller the gear ratio should be.

COIL SELECTION

How do we choose a reel? The most common case is buying a reel on the advice of friends. At the market or in a store, you can consult a seller, but this path is fraught with fraud. It’s best to figure out what’s what by holding the coil in your hands and analyzing its circuit. Everything stated below is on the conscience of the author, as it bears the imprint of his experience.

The most important condition for choosing a reel is its purpose for a particular fishing method. If an angler wants to engage in several types of fishing, then ideally he should have a separate reel for each fishing method. When choosing a reel, think about what baits, what kind of fish and in what conditions you are going to fish. By conditions you need to understand: will you fish more often from the shore or from a boat, what kind of bait (light or heavy) will you use. It is convenient to focus on the diameter of the fishing line that you will use. It is not recommended to use fishing line with a breaking load greater than that of the fishing line indicated on the spool.

Reel compatibility is given for monofilament line; three diameters are usually indicated, for example, on the spool of the Shimano Twin Power 2500 FA reel it is written: 0.18 mm - 290 m, 0.20 mm - 240 m, 0.25 mm - 160 m. If you If you want to use braided fishing line, then its breaking load should not exceed the breaking load of fishing line with a diameter of 0.25 mm (for our example).

Today 0.25mm lines can handle 6 to 8kg, so all you can afford for this reel is 0.1-0.12mm braided line. If you want to use a more powerful braided line, then you need a larger spinning reel or a multiplier.

Having decided on the size of the coil, go to the store. Taking the reel in your hands, make sure that it has a soft, silent motion, the line arc is easily reset to the working position, the reverse stop function is performed, the spool is easy to remove and put on, the braking system works smoothly.

How many ball bearings should there be in a reel? The minimum required number of bearings in a reel is four: a central bearing in the rotor, two at the ends of the drive gear axis and one in the line roller. They produce reels that have from 1 to 14 ball bearings installed in their mechanism. I believe that it is better to purchase a reel with a small number of bearings, but from leading manufacturers, than from a little-known company, but with a large number of bearings.

In the diagram of the coil you can see which spring is installed in the return mechanism of the line laying arc. Preference should be given to a multi-turn spring, as discussed above. The diagram will also help determine the type of mechanism responsible for moving the spool back and forth.

And if funds allow, you should choose a reel with a screw feed of the spool, it is also called an “endless screw”. It is advisable that the reel you purchase has one or two spare spools. This makes the reel more versatile, as it allows you to use line of different diameters for different fishing conditions.

You should know that once you purchase a reel, you are left alone with it. Not a single company producing spinning reels yet has a representative office in our country. This means that we do not have warranty workshops, competent specialists or spare parts. Therefore, you must treat your reel with care and use it correctly.

REEL CARE

From a technical point of view, inertialess coils are a rather complex and precise device. Proper and competent maintenance of the reel will extend its service life for a long time. Do not allow sand and dirt to get on its moving parts. If the internal mechanism of the reel is enclosed in a housing, then the handle, line guide, and line guide roller are located outside and can become dirty if the reel falls into sand or water. In this case, the coil must be washed, dried and lubricated.

Coil lubrication. It is advisable to lubricate the coil with lubricants intended for coils, which are allowed in two types: thick and liquid. Grease is used to lubricate gears, bearings and slowly rotating parts of the reel. Liquid lubricant is used to lubricate the main axis of the reel and the line roller.

Before lubrication, the reel is disassembled and each part is washed with Galosh gasoline using a brush. Then all the parts are dried on a sheet of clean paper, lubricated and the coil is assembled, checking the drawing that is usually included.

Backlash in the coil. An inertia-free reel is a mechanical device, and it is impossible to avoid the absence of backlash in it, otherwise the reel simply will not rotate. Anglers are usually irritated by excessive play and wobble in the reel. The better the quality of the reel, the smaller the tolerances its mechanism is created with and, accordingly, the smaller the backlash in it will be. Reducing backlash is not an easy procedure and requires skills, abilities and the necessary parts: adjusting washers, bearings, and sometimes the use of galvanization. Therefore, unless you are a highly qualified mechanic, eliminating the backlash yourself can have irreversible consequences for the reel mechanism.

Related articles:

Types of hooks for predatory fish

Sinkers for float rigs

Tackle "Rubber"

Tackle "Spring"

Useful sections of the FishingSib forum about spinning reels

- Independent maintenance of an inertia-free coil

- Repair of inertia-free reels

- All about lubricants for spinning reels

- How to get rid of a “beard”?

- about spinning reels

Comment provided by FishingSib website user Kostiksol:

— A 3000 dive size is equivalent in timber capacity to a 4000 Shimano, but if we take the middle class, then in terms of power they will not be equivalent. The same (for example) biomaster 4000 will be more powerful than 3000 caldium (or another generation of kixoids). Here it is better to focus on the weight of the bait and the method of fishing, i.e. give clear recommendations.

It is best to check the rotation of the roller with the edge of a piece of paper; it should rotate easily with light pressure. (this is one of the priority factors when choosing a copy in a store, along with the ease of operation of the main mechanism).

The bail can most often slam shut if the rotor brake is poorly implemented (when casting, the rotor rotates), you need to open the bail and turn the rotor by hand, it will rotate, but there should be a feeling of resistance.

You can check the side of the spool with your fingernail; if you run your finger along the perimeter of the circumference, you may not feel small nicks. Bullies will cut the cord. This will have little effect on range.

The bearings do not knock, but make noise (rustle). Even in the trash, a dead and unusable bearing (even with sand) never gave a ratcheting sound when it was part of an assembled reel.

Friends, fishermen, if you have any other advice for beginners, or perhaps instructions in this difficult matter, feel free to share them. After all, sometimes you miss the advice of a more experienced fisherman, especially when you decide to purchase such interesting gear as a spinning reel.

Cloudflare Ray ID: 63aa0adf9965bf6e • Your IP: 195.64.208.251 • Performance & security by Cloudflare

- mm/M 0.20/240 0.25/160 0.3/110

- lb/YDS 4/355 6/225 8/175

Content

- Selecting drive gear axial play

- How to secure the rotor locknut?

- Elimination of axial play of a fixed knob

Every year we are faced with the need to service a spinning reel. Usually, cleaning and lubricating the insides is not difficult. But what to do when coil maintenance requires more? How to determine and eliminate the cause of the “growling” of the coil? How to restore a damaged part? Yes, we can always put it in the hands of a specialist by paying for his services. And in a number of cases, this will be the right decision. However, our forum has accumulated a lot of useful information on this topic and we considered it very useful to prepare a series of articles that will touch on some topics of self-service of inertia-free machines.

Articles will be generated based on materials from user Prank in the discussion topic “Independent maintenance of an inertia-free coil.” The contribution of Vladimir (Prank) to the development of the topics of inertia-free and multiplier reels and, in particular, repairs, modifications, and various nuances of operation is difficult to overestimate. There is so much constructive and correctly presented information that even in a series of articles we will only touch on a small part.

Today we’ll talk about how to eliminate some of the play and movement of the rotor nut.

Marking of spinning reels.

Each reel is manufactured with certain parameters and functions. The manufacturer applies special markings to the product so that you can quickly understand the main capabilities of the reel. So, let's highlight the most important markings:

This marking is perhaps the most noticeable and eye-catching. It designates the capacity of the spool for fishing line or cord and usually consists of a multiple of 500 or 1000.

- mm/M 0.20/240 0.25/160 0.3/110

- lb/YDS 4/355 6/225 8/175

It’s more clear here: you can wind 240 meters of 0.2 fishing line on a reel, etc. The bottom marking is expressed in lb (pounds) - breaking strength (1 pound = 453.6 grams) and in yd (yards) - length (1 yard = 91.4 centimeters).

Gear ratio - gear ratio (PR).

This marking indicates the number of times the line guide rotates around the spool per revolution of the reel handle. Those. it characterizes the speed of winding the line onto the spool and is determined by the digital proportion.

Ball bearings — number of bearings.

Free-wheeling reels use both plain and antifriction bearings. They are responsible for the quality of movement of the line guide and the handle.

You can also notice that the more bearings there are in the main components of the reel, the easier it is for the mechanisms to transfer loads. But the most important thing is the quality of the bearings. After all, their wear leads to increased backlash, misalignment and jamming of the gear pair. Provided that the quality of the bearings is at a high level, we can assume that 4 of them are sufficient: 2 along the axis of the handle, 1 in the rotor head and 1 in the line roller.

These are the main markings that will help the fisherman choose a reel suitable for a particular type of fishing. Now let's move on to classification.

AN ORIGINAL MAG SEALED OIL for DAIWA REELS IS EXPECTED! Coming soon.

In this article we’ll talk about bearings. We’ve finally gained enough experience and the necessary information. Noise, rustling, etc. We'll talk about everything

Hooray. Launched YouTube channel Reelmaster

PS I will supplement the reviews with interesting information. I hope my articles will help you choose the right tool. If you are interested, register. We will send you news by email. I have a lot more in store

WE SHIP AROUND THE WORLD WE SHIP WORLDWIDE! Almost all products that... AN ORIGINAL MAG SEALED OIL for DAIWA REELS IS EXPECTED! Coming soon. Smith Ferrule Wax has arrived. Finally the doctor arrived.

How to remove play on the handle of a spinning reel.

How to remove play on the handle of a spinning reel.

Over time, even high-quality reels from reputable manufacturers require maintenance and minor repairs. No matter how careful the owner is, during operation it is still not uncommon for sand, dirt, or water to get into the reel mechanism. In these cases, you should clean all internal components and mechanisms, and when bathing the reel, be sure to replace the lubricant. Even if there is no visible contamination, then at the end of each fishing season, maintenance of any reel is necessary, since the reel’s lubricant loses its properties. Dust and moisture somehow penetrate inside, which leads to increased wear of gears, souring of bearings and other problems.

Even with annual autumn maintenance of the reel, the gear teeth gradually wear out, which leads to the formation of play on the reel handle. The gears of the worm pair are most susceptible to wear. If you continue to use a backlash coil, it will soon fail because the backlash will break the gear teeth and bearings. This play can be reduced by placing an additional washer of the required size and thickness between the reel housing bearing and the large (main) gear. Unfortunately, it is not always possible to select such a washer: either the thickness is not suitable, or the diameter of the mounting hole is wider than necessary, or the washer is too thick. If the thickness of the washer can still be managed with the help of a file, sandpaper and grueling painstaking work, then with the mounting hole it is even more difficult. There is a way out in this situation: you need to take a plastic bottle and make a washer of the required size from it. To do this, cut out a piece of the bottle, then select a screw with a diameter slightly smaller than the hexagonal leg of the main gear.

This is where we need the puck-

This screw, which was picked up, heats up to red and it makes a hole in a cut-out piece of a plastic bottle (you can use the cap of a ketchup bottle, and a drill with a drill of the required diameter greatly simplifies this procedure! But I didn’t have one on hand.)

After which the melting around the burnt hole is ground off with a needle file. Then a washer, which was removed from the spool, is applied to the workpiece, and its outer diameter is outlined using an awl. Next, a plastic washer is cut out with good scissors and a needle file is used. With its help, the washer is given the required thickness, all unevenness in the cutting is removed, and sandpaper finishes what has been started. If the mounting hole is a little smaller and the washer does not fit, the hole can be enlarged using a reamer. The washer should snap into place without effort, but should not dangle on the axle.

Here's what happened -

If you made a mistake with the inner diameter (it turned out larger), then it is better to make a new washer. The washers, bearings and all gears are lubricated with grease, and the grease on the GP gear should be thicker than on all other bearings and assemblies (you can use automotive lithium or buy a special one for fishing reels.). It is also necessary to understand that pressing the main gear too tightly against the shaft worm leads to increased wear of the pair and the softness of the reel will decrease. If the coil spins tightly after assembly, then the thickness of the washer should be further reduced. There should still be a slight gap between the gears.

It happens that over time, the teeth of the main gear seriously wear out, causing unnecessary noise and rumble when the handle rotates. This “sore” can be cured by grinding down the gear teeth a little, about a third of a millimeter. This can be done with a wide flat file, and then also add a washer. After a few fishing trips, the gears will wear in and the reel will be able to last a couple more seasons.

In this simple way you can extend the service life of the mechanism for more than one season. We should not forget that the reel mechanism wears out faster due to improper fishing and overloads. No matter how famous the company is, no one will make platinum gears. A spinning reel is not a winch and the fish should be caught using the pumping method.

It would not be amiss to add that the nut securing the line guide body can have a left-hand thread, it all depends on the reel model and the imagination of the manufacturer.

I wish you to avoid breakdowns of gear on the pond and low-level incidents!