Spools for fishing reels: material, shape, size

Spools for fishing reels are an integral part of them, and a lot depends on the quality, shape and material of the spool. So, the main task of the spool on a reel is to collect and remove the base wound on it: fishing line or braid.

For this purpose, the reel is equipped with a special line-laying arm, which, when the reel handle is rotated, winds the line directly onto the spool. For professional fishermen, this information will sound quite simple and natural, but for beginners it may be useful.

Principle of operation

during casting, the line passes through the side cheek of the stationary spool to prevent excess line from being thrown out. The fishing line is wound onto the spool using a special line layer. At the moment of casting, it is moved to the side, no matter what prevents the free release of the line. By turning the handle of the line layer, the line falls on the roller there, with the help of which the line is wound onto the spool. The spool can be attached in 2 ways: using the end button on the lock or rigidly. The last option is preferable, because makes it possible to change bobbins.

For tasks that require maximum load on the line when pulling fish, a brake is used, which can be adjusted front or back. This could be a special thumb on the spool or a handle (used more often and works better). Switches of various types (flag, slide) are used to operate the brake system. Slide-type switches are easy to use. They are located at the bottom or back of the reel body.

The transmission mechanism is located in the housing. To ensure reciprocating motion when winding the spool, and at the same time increases the speed of rotation of the line guide.

Spool material

Reel spools can be made from a variety of materials, ranging from cheap, low-quality plastic to high-tech titanium or aluminum alloys, which are highly hard and less susceptible to scratches. There are also models made of composite materials, which are very durable and lightweight, but also expensive.

Spare spools are ideal for backing as they are the same size as the main spools.

Briefly about backing: wind the main line onto the spare spool, then wind the backing line (backing line). Wind it until there is 2-3 mm left to the end of the side, then cut the line. Next, wind both lines onto the main spool. Thus, the main line is obtained outside, and the backing is under the main line.

Plastic spools are used only on cheap reels, or they are spares, but no one likes to use them. It is better to avoid reels with plastic spools, and it is worth purchasing something better for fishing.

Aluminum spools are the most popular these days; they are quite reliable and lightweight, but it is better not to drop them, since even a small burr on the spool, in the area where the line comes off, can cause many problems.

The main problems with scratches on the spool include: worse sliding of the fishing line, less distant casting, accelerated wear of the fishing line, and in general, because of this, a beard may appear on the fishing line.

The line coming off the reel must experience minimal friction in order for the cast to be as far and smooth as possible, therefore the surface of the reel spool must be very smooth and without damage.

Spinning reels: line lay, spool

- VK

The spinning reel (hereinafter simply reel) has become widespread among fishermen due to its versatility, functionality and ease of use. Let's look at the main functions of the reel: line laying, braking function, reverse blocking, gear ratio. How to choose a reel and properly care for it. Content:

- LAYING THE LINE

- BRAKING FUNCTION. FRICTION BRAKE

- BLOCKING REVERSE. ANTI-REVERSE

- SPOOL

- GEAR RATIO

- COIL SELECTION

- REEL CARE

LAYING THE LINE

The forward-backward spool feed mechanism and the line guide installed on the reel rotor are responsible for laying the line in the reel. There are two types of spool feed mechanisms: an endless screw (photo 1), which provides the best line winding, and a “locomotive” type rocker system (photo 2).

photo 1

photo 2

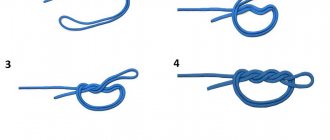

The line laying device consists of a line laying arc, a mechanism for returning the arc to the working position and a roller. For a long time, the elastic element of arc return was a spring made of several turns of wire with long tangent ends (photo 3).

photo 3

When cocking the line-laying arc, the spring worked to twist the coils, which led to significant stress in the hardened wire and quite frequent breakages. I had to take spare springs with me when fishing. Then, first in expensive and then in cheap coils, “long-lived” multi-turn springs appeared, working not to twist the coil, but to compress the interturn distance of the spring (photo 4). Some coils provide fixation of the cocked arc, preventing its spontaneous release.

photo 4

The latest reel models use a system that slows down the reel rotor when the line arc is retracted. This system completely eliminates unauthorized release of the arc during casting.

Automatic reset of the line laying arc occurs when the handle rotates when the rotor collides with the eccentric in the reel body. Although this function is provided by the design, it should be used only in emergency cases, since the consequences of shock loads lead to premature failure of this unit. Most experienced anglers move the line arc to the hand winding position.

The line-laying arc is usually an elastic stainless steel wire bent in a special way. Violation of the bending shape leads to its incomplete folding, and therefore to spontaneous closure when casting. It happens that after closing the arc, the line remains on it, without getting onto the line roller, which gradually leads to damage to the arc. As a rule, this defect occurs when the arc is deformed, so you need to handle this part of the coil very carefully.

The line roller is in direct contact with the fishing line, so the quality of its surface and ease of rotation during winding are a guarantee that the fishing line will not be damaged. Typically the roller is made of bronze, plated with hard chrome and polished. In expensive reels, the roller must have a miniature ball bearing and a hard, wear-resistant coating made of golden titanium nitride. The first sign of trouble with the roller is uneven wear of the coating from its surface and cuts appearing in it. This means that the roller has stopped rotating or rotates with difficulty. Therefore, you need to very carefully monitor the condition of the line roller, lubricating it at least once every 2-3 fishing trips.

BRAKING FUNCTION. FRICTION BRAKE

The reel's braking system allows you to land fish without the risk of breaking the line. Jerks of the fish, the force of which exceeds the value of the set braking force, leads to automatic slipping of the spool and the line coming off.

The friction brake can be located directly in the reel spool (front brake) or located at the rear of the reel body (rear brake). Both systems have their advantages and disadvantages. The advantages of the rear brake are ease of adjustment when playing fish (the ability to quickly replace the spool). Disadvantages include coarser tuning and less braking force (compared to the front brake).

The front location of the friction brake reduces the size of the reel and makes the brake more finely adjustable. Structurally, the brake of any reel is a set of alternating steel and non-metallic disks, compressed when the clamping screw is tightened. Do not allow sand to get between the discs, and also do not lubricate them excessively.

BLOCKING REVERSE. ANTI-REVERSE

This system blocks the reel rotor, preventing it from spinning in the direction opposite to winding. During fishing, the reverse stop switch must be turned on, which allows you to free one hand at the final stage of landing the fish to grab the fish with your hand or in the landing net.

Today, the most advanced system is the infinite antireverse or instantaneous stopper. This system turned out to be so successful that it is gradually replacing all others and is already used in relatively inexpensive reels. Structurally, it is a roller bearing, the rollers of which can be forced to move along the radius of the bearing. When the stopper is engaged, the rollers move towards the overrunning clutch located on the rotor gear, blocking its backward movement. When turned off, the rollers move away from the overrunning clutch, allowing the rotor to rotate freely in both directions.

SPOOL

Reel spools are made of durable plastic or metal. Reels are also produced whose spools are made of carbon fiber and have a metal side. One of the best options is a metal spool with a titanium nitride coated carbide front. When using a reel, you need to pay attention to the quality of the surface of the spool side, which determines the flight range of the bait and the safety of the fishing line surface. Any scratches, burrs or depressions that occur must be removed with fine sandpaper and polished.

There is an opinion that plastic spools cannot be used when fishing with braided line. However, if you clean and polish the seams formed when casting the spool, the spool becomes quite suitable for braided fishing line.

The spool usually holds more than 100 m of fishing line needed for fishing. Therefore, to fill the excess volume, inexpensive monofilament fishing line is wound under the main line. In order for the line to come off the spool when casting without tangling and significant resistance, the spool must be filled with line, not reaching 2-3 mm to the upper edge of the front edge.

Daiwa has developed an ABS (anti backlash system) spool. This spool has an increased diameter and is made in the form of a truncated cone facing the base. This design allows you to avoid involuntary dropping of line loops at the time of casting, and also increases the casting distance. Therefore, the abbreviation ABS among American professional fishermen began to be read as “advanced ballistic system,” which translated from English means “advanced ballistic system” (photo).

Shimano has proposed a simpler solution to this same problem and equips its reels with a set of shims. The fisherman can choose the type of winding at his discretion - cylindrical, with a slope towards the front or rear side of the spool.

GEAR RATIO

The gear ratio is the number of revolutions of the reel rotor per revolution of the handle. Numerically, it is equal to the ratio of the number of teeth of the drive gear to the number of teeth of the rotor gear. Powerful traction reels have a small gear ratio - from 3.6:1 to 4.6:1. A gear ratio close to 5:1 is considered the most universal.

Higher-speed reels with a gear ratio of 6:1 - 7:1 are used in float fishing on match rods. The high gear ratio increases the tightness of the line winding, making it easier to fish with such rods. The choice of a reel with a certain gear ratio is determined by the size of the expected trophies and fishing conditions. The larger the fish that can be caught and the more severe the fishing conditions, the smaller the gear ratio should be.

COIL SELECTION

How do we choose a reel? The most common case is buying a reel on the advice of friends. At the market or in a store, you can consult a seller, but this path is fraught with fraud. It’s best to figure out what’s what by holding the coil in your hands and analyzing its circuit. Everything stated below is on the conscience of the author, as it bears the imprint of his experience.

The most important condition for choosing a reel is its purpose for a particular fishing method. If an angler wants to engage in several types of fishing, then ideally he should have a separate reel for each fishing method. When choosing a reel, think about what baits, what kind of fish and in what conditions you are going to fish. By conditions you need to understand: will you fish more often from the shore or from a boat, what kind of bait (light or heavy) will you use. It is convenient to focus on the diameter of the fishing line that you will use. It is not recommended to use fishing line with a breaking load greater than that of the fishing line indicated on the spool.

Reel compatibility is given for monofilament line; three diameters are usually indicated, for example, on the spool of the Shimano Twin Power 2500 FA reel it is written: 0.18 mm - 290 m, 0.20 mm - 240 m, 0.25 mm - 160 m. If you If you want to use braided fishing line, then its breaking load should not exceed the breaking load of fishing line with a diameter of 0.25 mm (for our example).

Today 0.25mm lines can handle 6 to 8kg, so all you can afford for this reel is 0.1-0.12mm braided line. If you want to use a more powerful braided line, then you need a larger spinning reel or a multiplier.

Having decided on the size of the coil, go to the store. Taking the reel in your hands, make sure that it has a soft, silent motion, the line arc is easily reset to the working position, the reverse stop function is performed, the spool is easy to remove and put on, the braking system works smoothly.

How many ball bearings should there be in a reel? The minimum required number of bearings in a reel is four: a central bearing in the rotor, two at the ends of the drive gear axis and one in the line roller. They produce reels that have from 1 to 14 ball bearings installed in their mechanism. I believe that it is better to purchase a reel with a small number of bearings, but from leading manufacturers, than from a little-known company, but with a large number of bearings.

In the diagram of the coil you can see which spring is installed in the return mechanism of the line laying arc. Preference should be given to a multi-turn spring, as discussed above. The diagram will also help determine the type of mechanism responsible for moving the spool back and forth.

And if funds allow, you should choose a reel with a screw feed of the spool, it is also called an “endless screw”. It is advisable that the reel you purchase has one or two spare spools. This makes the reel more versatile, as it allows you to use line of different diameters for different fishing conditions.

You should know that once you purchase a reel, you are left alone with it. Not a single company producing spinning reels yet has a representative office in our country. This means that we do not have warranty workshops, competent specialists or spare parts. Therefore, you must treat your reel with care and use it correctly.

REEL CARE

From a technical point of view, inertialess coils are a rather complex and precise device. Proper and competent maintenance of the reel will extend its service life for a long time. Do not allow sand and dirt to get on its moving parts. If the internal mechanism of the reel is enclosed in a housing, then the handle, line guide, and line guide roller are located outside and can become dirty if the reel falls into sand or water. In this case, the coil must be washed, dried and lubricated.

Coil lubrication. It is advisable to lubricate the coil with lubricants intended for coils, which are allowed in two types: thick and liquid. Grease is used to lubricate gears, bearings and slowly rotating parts of the reel. Liquid lubricant is used to lubricate the main axis of the reel and the line roller.

Before lubrication, the reel is disassembled and each part is washed with Galosh gasoline using a brush. Then all the parts are dried on a sheet of clean paper, lubricated and the coil is assembled, checking the drawing that is usually included.

Backlash in the coil. An inertia-free reel is a mechanical device, and it is impossible to avoid the absence of backlash in it, otherwise the reel simply will not rotate. Anglers are usually irritated by excessive play and wobble in the reel. The better the quality of the reel, the smaller the tolerances its mechanism is created with and, accordingly, the smaller the backlash in it will be. Reducing backlash is not an easy procedure and requires skills, abilities and the necessary parts: adjusting washers, bearings, and sometimes the use of galvanization. Therefore, unless you are a highly qualified mechanic, eliminating the backlash yourself can have irreversible consequences for the reel mechanism.

Related articles:

Tackle for catching pike with dead fish

Types of feeder feeders

Types and loading of floats

Sinkers for float rigs

Spinning reels

T

Now regarding the physical design of the spools.

First is the size, large spools are placed on large reels, which are usually used for catching large fish at a great distance from the shore.

For example, for feeder fishing, spools of size 2500-4000 are suitable. This number indicates their size, and accordingly the capacity of the fishing line. For more information about this, ask sellers in fishing stores; first of all, look at reels from Daiwa and Shimano .

For spinning players, it will be especially useful to read about choosing spinning reels; the article describes the main points that you should pay attention to when buying a spinning reel.

Next, let's look at the depth of the spool, which is also important. Deep reels are designed for winding long fishing line with a large diameter, and using them there is a problem of strong friction when the fishing line comes off the spool.

A deep spool without backing, in which the wound line is located far from the outer sides of the reel, creates excessive friction, which worsens the line flow and, accordingly, the casting distance. In such cases, you need to first wrap the backing line around the inside of the spool.

The main line you will be fishing with should be 2-3 mm deeper from the side, this is the optimal distance for winding on the spool.

There are also shallow long spools with a large capacity that are ideal for both feeder and carp fishing. Long spools are called "Long Cast".

Spools can have a cone-shaped shape, and the cone can be either in one direction or the other.

What you should pay attention to when choosing a “meat grinder”

We will not talk about choosing a reel for a certain tackle, but about what you should pay attention to when buying and make sure whether it is worth buying or not. Since a beginner will have to make his choice from a mass of budget options, and, frankly speaking, they often have many disadvantages.

So.

Criteria for choosing a budget spinning reel

- Having a spare spool is a useful purchase. By winding fishing line or braided cord with different characteristics, you expand your possibilities for lures and fishing conditions. The spare spool can be metal or plastic. The last option is more common. Be sure to inspect the sides. The presence of burrs, scratches and casting defects is unacceptable. The sides of the spool must be smooth.

- Having screwed the reel handle, be sure to check the convenience. No backlash. The move should be soft, without jerking. Smooth running may initially be absent, since the mechanisms have not yet gotten used to it, the lubricant has not dispersed, or you buy it in a cool room, but nevertheless, spin a few reels from the counter and feel the difference.

- Checking the friction brake. The drag is one of the most important characteristics of a reel for any type of fishing.

- The reel clutch adjusting nut should be easy to use. This is regardless of the type of inertia-free brake - it has a front brake or a rear brake.

- We tighten the clutch until the spool is completely fixed and you cannot turn it by hand (do not overdo it). Then we begin to let go little by little. Make half a turn and check the brake stroke. And so on until the spool begins to rotate freely. What are we checking? The friction brake can be short or long. A short one is when you have made half a turn with the nut, and the spool is already tightened. We immediately reject this option. When biting a large fish, when at the moment of reeling it is necessary to lower the clutch and let the fish “walk” and take part of the fishing line from the reel, we will not be able to do this. The line will simply come off the spool easily, and a worthy trophy may go away. We are also not interested in the long brake stroke. We need a middle option, when the spool reacts to every half-turn of the nut. Of course, it will be difficult for a novice fisherman to determine the correct movement of the clutch for the first time. Here I can give advice - try setting the brake on an already tested reel with friends or acquaintances.

- A slight longitudinal play of the spool is always present.

- The line roller simply must have a bearing. If it is missing, refrain from purchasing. The fact is that this knot twists the fishing line when laying. Inertialess reels themselves are not bad at spinning a fishing line or braided cord along the axis, but if a roller also helps with this, it’s a bad thing.

- The absence of self-resetting of the line guide arm is checked as follows: fold the arm all the way and, holding the reel leg, shake sharply several times. The line handler must be in the open position.

- Pay attention to the reverse stopper. We turn it on, rotate the handle and look at its play when braking. If the handle locks immediately and does not dip back, this is an indicator that the instant stopper works well. In the off position, the handle should move freely forward and backward.

As I already said: “ A spinning reel is matched to a spinning rod .” This rule also applies to other types of models. If you purchase everything together, be sure to attach the reel to the rod. Make sure the reel seat secures both parts tightly. No backlash or chatter.

And be sure to check the balance of the reel and rod. Believe me, fishing is often a long process, albeit a favorite one. But after a whole day of use, your hands may hurt. To reduce this possibility, you must have a convenient, balanced tool.

The balance of the spinning reel and spinning rod is checked in a simple way. Having fastened both parts, we simply try to balance the spinning rod on the index finger. The closer the balance is to the reel leg, the better.

We consider the appearance of the coil last. It does not affect performance characteristics.

Replacement reel spool: plastic or metal?

The spinning reel is equipped with two spools, one of them is metal, the other is plastic. Which one is the main one and which one is the spare one? What a question? Of course it's metal. Many of us, if we don’t immediately throw the plastic one away, then put it in a distant box, as if it never existed at all. Now, if the spare spool for the reel is also made of metal, then such a reel is in noticeably greater demand for this reason alone.

Why so? It's simple: a plastic spool is cheaper and therefore does not inspire confidence. Our perception of it is especially affected by the fact that all the cheapest radically Chinese reels are equipped with plastic spools. Plus you still have doubts about its strength and reliability.

Well, the aesthetics - the plastic spool on the reel looks a little rough and clumsy. But if you approach it objectively, which spool is still better to choose? The first argument in favor of a plastic spare spool is its weight. No, it is not much less than that of a metal one, but judging by how we sometimes meticulously study their technical characteristics when choosing reels, minus 15-20 g makes a difference. Moreover, these grams leave the front part of the reel, which benefits the overall balance of the tackle.

Strength? But we are not going to crack nuts with a spool. During normal fishing mode, it is the spool that experiences minimal loads. This is not the coil element that needs to be reinforced or strengthened.

General roughness of performance? In part, perhaps yes. But the internal filling (friction brake assembly), as a rule, is no different from a similar assembly of the main (metal) spool. The differences relate to the edge through which the line runs when casting. On it as a rule. a microstep can be traced. formed due to imperfect alignment of the mold halves. The problem can be solved very easily, within a minute, using fine-grained sandpaper or replacing the spool on an inertia-free reel.

But as for vulnerability to shocks and other mechanical influences, here a plastic spool, in my experience, is even preferable. If you don’t take expensive reels, in which the working edge of the spool is protected by titanium nitride (and by no means of leaf thickness), then the aluminum spool imprints on all the contacts as if made of plasticine: dents. scratches. Even with careful handling of the coil, they still come from somewhere. Some of these scars can be rolled up using the side surface of a sewing needle, but you still need to constantly remember about the problem. But a plastic spool for a reel has a higher threshold for susceptibility to this kind of influence, so it’s somehow easier with it.

Metal spool and its features

Depending on the material of the spool, the price may vary significantly. It is made of metal, plastic, titanium or aluminum. There is another option that deserves special attention - composite, which allows you to reduce the weight of the part while maintaining strength and reliability. Depending on the characteristics of the material, the practicality and durability of using the coil element will differ. The most common material remains metal. The technical characteristics meet the requirements of the fisherman, and the cost is always in an affordable range.

The need for reinforcement of coil parts

A high-quality metal spool cannot compare with a plastic one, although some experts prove the opposite. If you have a limited budget, but purchasing is a priority, feel free to buy the second option. It is this element of the reel that does not experience significant load during normal fishing mode. For this reason, reinforcement and high requirements regarding strength are not relevant, but subject to temporary use. In all other cases, care must be taken to have metal replacement elements for the coils.

Fishing reels for carp

8 minutes Author: Yuri Polyakov 238

In the rapidly growing trend of fishing - carp fishing - there are no trifles. The tackle must be both convenient for work and allow you to pull trophy fish from the water, reaching a huge weight of up to twenty kilograms. Therefore, you should pay increased attention to the selection of all elements of the carp bottom, from the carp rod to the hook.

The subject of our discussion today will be carp fishing reels. We will consider all aspects related to the use of this mechanism: fishing requirements, choice depending on characteristics, top models from leading manufacturers, budget options for meat grinders.

Requirements

The choice of reel parameters is dictated directly by our rival on the pond - His Majesty Carp, from whose behavior the basic requirements for the mechanism arise:

- Often the fishing point is located at a decent distance from the shore, which means that the spool must contain a sufficient amount of fishing line to ensure long casting, and the cord itself is by no means small in diameter. Sometimes the thickness of the carp monofilament reaches 0.7 millimeters.

- The weight of the intended trophy leaves its mark on such a parameter as traction force; it must be consistent with the mass of the fish being caught.

- Sometimes carp stand in so-called “strong” places, fishing from which forces you to quickly change the moment of force, dampen jerks and level out “dead” holds. This makes it necessary to have a powerful, clearly adjustable clutch.

- Fishing for a trophy involves changing the direction of its jerks in different directions, entailing alternating tension and weakening of the fishing line. This forces the use of reels with a large spool, which will allow you to quickly pick up the slack in the cord.

About the buyrunner

An important factor in how to choose a carp reel is some inertia and regularity of carp fishing. There are no frequent casts, as in a spinning rod, or frequent bites, as in a feeder.

The rods are mounted on rod pods and equipped with bite alarms. To prevent a pecked carp from dragging the gear into the water, they used to remove the bail from the reel to allow the line to flow freely, but now this is no longer necessary. The design of a carp fishing reel includes a mechanism called a baitrunner. It is a lever that locks the spool. If you turn it off, the line will begin to unwind from the reel without any effort, allowing the fish to calmly leave without encountering resistance.

The spool is locked back by switching the lever or rotating the knob, and the reel begins to operate in normal mode. Thus, we can conclude that a modern reel for catching carp or carp must certainly be equipped with a baitrunner. This mechanism will help protect the gear from the sharpest initial jerk of the fish.

Mechanism parameters

Now we will describe in more detail all the parameters characterizing reels for carp fishing. It should be noted that in carp fishing, only inertia-free models are used; in the fishing community, they are often called “meat grinders” due to some external similarity with a popular piece of kitchen utensil.

The reel of carp meat grinders should be spacious; when choosing, be guided by its timber capacity. The optimal volume of the spool is considered to be one at which it can accommodate an amount equal to two hundred meters of fishing line with a diameter of 0.4 millimeters.

This selection criterion is also interesting. If you are going to fish with monofilament line, you should choose a straight spool model. When using braid, it is better to use a reel that provides reverse cone styling. In the first case, the casting distance is extended, in the second, the probability of dropping loops is reduced.

Bearings

Their number may vary, starting from four pieces, two of which are placed on the handle. Another bearing is responsible for the rotation of the line roller. The rest provide a smooth ride.

This element is responsible for the performance of the reel in terms of its gear ratio. For inertialess ones it ranges from 4:1 to 7:1.

Reels with a gear ratio of up to 5.5:1 are considered traction, and those above this figure are considered high-speed. The Golden Rule of Mechanics works here: “We win in strength, we lose in distance, and vice versa.”

Forester

There are three main requirements for this mechanism:

- it is desirable that the bow does not close spontaneously;

- so that there is a bearing under the roller and not a bushing;

- so that the bow and roller are covered with a protective film of metal, most often titanium nitride.

We put it in last place, but meanwhile the reel brake is the main mechanism that regulates the force when fishing for fish. By changing it, you can tire even the strongest and most stubborn carp.

The clutch may be located in front under the nut securing the spool, then the model is called front-friction. Rear friction options are adjusted with a nut located at the bottom of the meat grinder.

Why is a graphite spool needed on a spinning reel?

How to choose a spinning inertia-free reel?

The modern range of inertia-free spinning reels is truly huge. There are hundreds of manufacturers, and each of them also has a lot of reel models, and, at first glance, all models look almost the same, and the difference in price can reach 10 times. How can you not get confused here? Well, let's start with the fact that at first glance all the coils are the same, but in fact the difference lies in the details, such as: quality of materials, build quality, perfection of engineering solutions, etc. But all these details directly affect reliability and ease of use of the reel.

Choosing a suitable spinning reel is even more difficult than the rod itself - there are too many different nuances in this matter. However, if you approach the issue thoroughly and sort everything out, the choice will be easy to make.

The main rule, which greatly simplifies the choice of a reel, is: “The reel should be matched to the fishing rod!” Or rather, depending on the fishing conditions: fishing method, size and type of fish. But we proceed from the fact that all fishing factors have already been taken into account when choosing a fishing rod, and the reel is selected as a harmonious addition.

So, let's start putting everything into pieces.

Materials used in reels

There are two materials that are used in the manufacture of reels: plastic and metal. At the same time, there are hundreds of types of plastic, each of which differs in strength and wear resistance. Metal in coils is also a broad concept, because even in one model, several types of metals can be used simultaneously. For example, the body may be made of titanium alloy, the spool made of machined aluminum, the line guide made of stainless steel, gears made of bronze alloy, etc. In the vast majority of cases, the reel design consists of both plastic and metal parts, although there are both all-metal and all-plastic models. It is not recommended to purchase the latter, since these products, to put it mildly, do not differ in quality.

Manufacturers are constantly trying to reduce the weight of reels while maintaining their strength. As a result of the pursuit of simultaneous strength and lightness, reels made of various lightweight and very durable metal alloys appear on the market every year. Yes, such models are not cheap, but they are worth it. In general, the best choice is a reel with an alloy metal body. But in no case should we write off reels with a carbon fiber body. Modern carbon fiber reinforced plastics are not inferior to metal in many respects, and in some respects they are superior to it. When choosing a reel based on material, you should most likely focus on price. Unfortunately, miracles do not happen, and for a low price you are unlikely to be offered a product with “super properties”. Well, for the high price, both a metal coil and a carbon fiber one will be equally good.

Gear ratio of inertia-free coil

The gear ratio is a parameter that means the ratio of one full revolution of the handle to the number of revolutions of the line layer. According to this parameter, coils are divided into high-speed and power. The gear ratio can be indicated on the reel body by the following expression: 5.0: 1, 5.3: 1, etc. This inscription means that one corresponds to one revolution of the handle, and the second number indicates the corresponding number of revolutions of the line layer. The higher the ratio, the faster the coil, and vice versa, the lower the ratio, the more powerful the coil. Power models include reels with a gear ratio of up to 5.0: 1 (4.0: 1, 4.3: 1, etc.), and high-speed reels include models with a gear ratio above 5.0: 1 (5.3: 1, 6.0: 1 and etc.). The speed qualities of the reel depend primarily on the size of the teeth of the main gear. But let’s not delve into such technical jungle; anyway, no one will let you disassemble the reel before purchasing. From a practical point of view, power reels are good for catching large fish, as well as for retrieving using “high-tension” baits. High-speed models have a smaller power reserve, but allow you to reel out the line very quickly, which is very important for certain types of fishing, for example, when fishing with a jig. The choice between strength and speed completely depends on the intended fishing objects - we hunt only for “crocodiles”, then we take a power model, and if you want more versatility, then the choice can be made on the “golden mean” - reels with a gear ratio of 5.0: 1, or with indicator close to this value.

Dimensions and weight of coils

As mentioned above, every year manufacturers bring lighter and lighter reel models to the market, without compromising their reliability. They do this for a reason, because the lighter the reel, the more pleasant it is to fish, but still going to extremes is also unacceptable. The main thing is that the weight and size of the reel are in balance with the rod. What is the balance of a rod and reel is difficult to describe, you need to feel it. Regarding the weight of the reel, there is an opinion that the weight of the reel should approximately correspond to two weights of the rod, plus or minus 30 grams. For example, the weight of the rod is 100g, which means the weight of the reel should be around 200g, plus or minus 30 grams. True, this rule is somewhat arbitrary, but in the vast majority of cases it works.

All reels have a so-called size, which is indicated in numbers: 500, 1000, 2000, and so on. But that’s not the problem; the classification of coil sizes is still not unified among manufacturers. Therefore, if you pick up a thousand-size reel from two different manufacturers, you can visually see a slight difference in size. Although, it is worth noting that most manufacturers still accepted the size classification developed by Shimano as a standard.

To choose the correct size reel, you need to take into account such rod parameters as length and test. Below is a table that describes the relationship between the technical parameters of the fishing rod and the size of the reel. We think the principle of the table is clear. Let's say we have a rod with a length of 220 cm and a test weight of 10-25 grams. Let's look at the table. Our spinning rod’s length falls into the “UP TO 240” category, and according to the test it falls more into the “15-30” category, therefore, the suitable reel size is 2000-2500.

The gear ratio is a parameter that means the ratio of one full revolution of the handle to the number of revolutions of the line layer. According to this parameter, coils are divided into high-speed and power. The gear ratio can be indicated on the reel body by the following expression: 5.0: 1, 5.3: 1, etc. This inscription means that one corresponds to one revolution of the handle, and the second number indicates the corresponding number of revolutions of the line layer. The higher the ratio, the faster the coil, and vice versa, the lower the ratio, the more powerful the coil. Power models include reels with a gear ratio of up to 5.0: 1 (4.0: 1, 4.3: 1, etc.), and high-speed reels include models with a gear ratio above 5.0: 1 (5.3: 1, 6.0: 1 and etc.). The speed qualities of the reel depend primarily on the size of the teeth of the main gear. But let’s not delve into such technical jungle; anyway, no one will let you disassemble the reel before purchasing. From a practical point of view, power reels are good for catching large fish, as well as for retrieving using “high-tension” baits. High-speed models have a smaller power reserve, but allow you to reel out the line very quickly, which is very important for certain types of fishing, for example, when fishing with a jig. The choice between strength and speed completely depends on the intended fishing objects - we hunt only for “crocodiles”, then we take a power model, and if you want more versatility, then the choice can be made on the “golden mean” - reels with a gear ratio of 5.0: 1, or with indicator close to this value.

Manufacturing companies

The most popular companies producing fishing carp reels are well-known brands representing companies from the USA, Japan, and South Korea. At the same time, many companies from the Middle Kingdom quickly entered the market. At present, Chinese meat grinders are almost as good as the summoned world leaders.

Below is a short list of the most popular brands:

- Daiwa,

- Kaida,

- Okuma,

- Salmo,

- Shimano

- Mifine,

- Abu Garcia,

- DAM

- Dragon,

- ESP,

- Volzhanka.