The so-called Danforth anchor, due to its characteristics and ease of manufacture, is one of the most popular solutions among experienced fishermen and lovers of outdoor activities on the water. In accordance with the current rules, any watercraft must be equipped with a device for holding the vessel. A factory product of this type is a very expensive pleasure. Therefore, most fishermen and owners of boats and yachts prefer to make such things with their own hands. Danforth's anchor drawings are in the public domain. And having a welding machine and several pieces of sheet iron in the garage, you can make an anchor that will not be inferior in its characteristics to factory analogues. This article provides a comparative description of existing types of devices for holding a vessel, and recommendations for their selection are given.

Historical information about the Danforth anchor

This type of device owes its appearance not to an inventive fisherman, but to the work of a group of scientists commissioned by the United States Navy. They developed several types of anchors, which a special commission of naval officers subjected to severe tests.

The events took place after the Second World War. On an April morning in 1948, a tugboat carrying representatives of the armed forces, as well as various US shipping organizations, set out to sea from a naval base near San Francisco. Having moved a sufficient distance from the shore, the ship turned against the current. A series of experiments followed. A dynamometer was attached to the chain, which made it possible to determine the maximum force that the product can withstand.

The Danforth anchor was the last to be tested, since the smallest hopes were pinned on it. However, the results were sensational. This design exceeded all expectations. Subsequent tests in various conditions and on various soils showed the unconditional advantage of the Danforth anchor over other types of devices for holding a ship. Currently, all sea and river vessels are equipped with similar devices.

Design requirements

The anchor must reliably hold the craft on the surface of the water, regardless of any difficulties and weather conditions. A good boat holding device can save the life of the entire boat crew in extreme situations. This indicator is achieved due to the good and thoughtful design of the product. However, in some cases, the ability of an anchor to hold a boat or yacht is achieved by increasing the mass of the latter. This approach is fundamentally wrong and gives rise to a whole bunch of problems.

Another important requirement is the ability to easily release the device for holding the boat if it gets caught.

An important place among the requirements for anchor mechanisms is occupied by compactness and the ability to resist corrosion (especially in sea water).

The importance of each of these requirements should be discussed separately.

Basic requirements for an anchor

There are quite a lot of requirements for the design in question. These include:

High holding force

As a rule, it depends on the mass of the structure. The boat must be securely fixed in one position despite the wind, current and movements in the craft. The structure should be easily and quickly removed from the hooks, since this phenomenon can be encountered quite often. It is important not to lose the anchor while fishing. The compactness of the design is also quite an important indicator. When transporting and while moving on water, many people strive to save space

It is also quite important that the anchor is not very heavy. The structure will remain in the water for a long time. It should be taken into account that prolonged exposure to moisture causes corrosion on the surface. Due to corrosion, the strength of the structure decreases significantly over time. Therefore, when making an anchor, you should use a metal that has anti-corrosion properties.

When making a homemade anchor, you should pay attention to the conditions under which the structure will be used: with strong vegetation, clogged bottom, rocky terrain, and so on.

Ability to provide significant resistance

Many novice and inexperienced fishermen mistakenly believe that any weighty blank can be used as an anchor device. This is a profound misconception, as they are convinced of at the very first time they go out on the water. And what kind of tricks and inventions they go to! Heavy stones, reinforcement, and so on are used. But everything is in vain! After the first significant gust of wind, the boat begins to blow away, and the bottom of the reservoir becomes polluted with various rubbish. After the fuss, the mood drops, the strength dries up, and there is no time for fishing. For this reason, it is necessary to have a normal device for holding the boat. It will also allow you to avoid an unpleasant audience with a water transport inspector and the payment of a significant fine.

Corrosion resistance of anchor

This requirement is important. Anchors made of ordinary ferrous metals, especially in aggressive environments (sea water), very quickly become unusable. Such a device may last for several years, but it will look simply terrible. For this reason, small anchors (Danforth and other types) are recommended to be made of stainless steel. Steels with high chromium content are expensive, but it's worth it.

Some fishermen manage to coat anchors made from ordinary quality steel with a layer of zinc or even nickel. This measure will somewhat delay the destructive corrosion process, but still, over time, rust beetles cover the surface of the product.

Requirements for ropes

Unlike the requirements directly for the anchors themselves, with the rope everything is quite simple. Any synthetic rope is perfect for this purpose. To hold a boat on the surface of a river or lake, a cable with a diameter of six millimeters is quite enough. However, such a rope will cut your hands when choosing an anchor. Therefore, it is better to use an end with a diameter of at least ten millimeters.

Tools and components for making a device for holding a vessel at home

The anchor of this design has a relatively simple design, which allows you to make a decent copy in a garage workshop. All you need for this is a set of tools and necessary materials.

First of all, you will need a good and reliable rope of sufficient length. On large ships, the anchor is held in place by steel chains, but to hold a small boat, a regular rope will do just fine.

You will also need sheet material. It is better if it is stainless steel, since such an anchor will last much longer. However, on the other hand, stainless steel is less amenable to processing and welding, so making a device for holding a boat from this material will take much more time and effort.

You will also need a steel bar (from which fasteners to the Danforth anchor cable will be made), a hollow metal pipe 30 centimeters long.

How to make an anchor for a PVC boat with your own hands - drawings and photos

Fishing without an anchor in current conditions, even the weakest, is simply impossible. Some may think that in a body of water without a current you can fish perfectly without an anchor, but this is not at all true. Almost all bodies of water have an underwater current, with rare exceptions.

Also, sometimes it’s simply unrealistic to go fishing in calm weather, so it’s imperative to have a PVC boat anchor with you. A fisherman equipped with an anchor can solve many more problems on the pond. And given the fact that making an anchor yourself is not very difficult, you should not underestimate it.

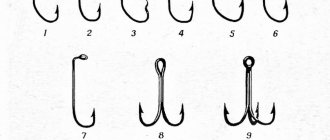

There are several types of anchors that are most popular among fishermen:

- Hall anchor model.

- The well-known cat anchor.

- Sensational anchor-Kurbatov.

- An anchor shaped like a fungus.

- A universal Danforth anchor that is suitable for fishing in any body of water.

Each type of anchor has its own disadvantages, but most of them are offset by the presence of advantages. In order to understand in more detail all the pros and cons, it is worth taking a closer look at the manufacturing process of each type of anchor.

A simple model of a collapsible anchor

In order to make such an anchor for a PVC boat with your own hands, you will need some details:

- A piece of metal pipe with a diameter of 2.5 centimeters and a length of about 27 centimeters;

- Nut and bushing;

- Two smaller pieces of metal and two larger ones;

- Two metal rings;

- Lead – about 2 kilograms.

The process of assembling a simple model of a collapsible anchor is as follows:

- It is necessary to secure the sleeve to the end of the pipe.

- Four metal pieces will play the role of anchor arms.

- The entire structure must be secured with a nut.

- Heated lead must be poured inside the tube (required to increase weight).

Read Fishing for crucian carp on a feeder

Kurbatov's welded anchor

To make such an anchor, fewer parts will be required; only the fisherman must have minimal knowledge and skills in working with a welding machine. Due to the welded construction, the assembly process is greatly simplified and the number of parts is reduced.

The list of required parts is as follows:

- Steel rod;

- Steel wire;

- Small pieces of metal.

The manufacturing process looks very simple and all dimensions are indicated in the diagram:

- Bend the steel wire into a spindle-like shape.

- Weld the remaining parts to the resulting structure.

- The anchor will be held at the bottom by the weight of the metal pieces.

Anchor cat

For inflatable boats, this type of anchor is considered optimal and will serve you well. The main advantage of such an anchor is its compactness, because when folded, the entire structure will take up minimal space inside the boat.

The light weight of the anchor has its advantages during transportation, but in strong currents and high wind speeds it will be necessary to add weight to the structure. The paws are fixed to a bent spindle made of thin metal or thick steel wire. You can change their location with a few simple movements.

Pyramid anchor

This type of anchor got its name due to the fact that to manufacture it you will have to make a structure in the shape of a pyramid. Most often, fishermen use sheet metal for manufacturing. Lead must be poured into this form to give the structure additional weight.

To ensure comfortable fastening of the anchor, it is necessary to insert a piece of wire until the lead cools. This will allow the wire to be firmly fixed in the anchor by the time the lead cools, and the reliability of such a design will be very high.

There is another way to make such an anchor without using lead. You will need to secure the metal plates so that a pyramid is formed (the size of the plates must be different). This is a very convenient method, since you can add and remove plates to increase or decrease the weight of the product.

To quickly replace the plates and change their number, you need to drill a through hole in each and insert a pin instead of a wire. This design is securely fixed using nuts. The plates must be assembled in ascending order, that is, so that the largest one is at the top.

Calculations, geometry and drawings of the Danforth anchor

The designer patented his invention. The document dated July 15, 1941 contains information about the design features and geometry of the anchor. The main ones are the following:

- The ideal ratio of parameters is achieved when the soil resistance area is 60% of the total area of the device. This figure cannot be less than 40%, since the performance characteristics of such an anchor will be extremely low.

- The slope of the paw of the product cannot exceed 75 degrees. Failure to comply with this condition will result in the anchor not being held in the ground.

- The angle of attack directly depends on what part of the product’s paw area is located behind the axis of rotation. In the case when this value is 35% of the surface area of the anchor arms or more, the angle can take values from 30 to 50 degrees. If the area of the paws behind the axis of rotation is less than 35% of the area of the paws of the product, the dimensions are set so that the angle of attack is 40-60 degrees. If the anchor is intended to operate on hard sandy soil, it must have a minimum acceptable angle of attack (40 degrees). If the device operates on a muddy swamp bottom, the angle of attack increases. This circumstance should be taken into account when designing and manufacturing such devices. If it is not known exactly in what conditions the device will operate (it is manufactured for subsequent sale), then this figure is usually 50 degrees.

- An important dimension of the Danforth anchor is the distance between the legs (more precisely, between their centers). When designing and manufacturing such products, it is necessary to strive to ensure that this indicator has a minimum value. This will reduce the significance of the emerging force pair.

Varieties

Homemade anchors for inflatable boats are divided into many types.

Here are the main ones:

- Kurbatov's anchor;

- "cat";

- Danforth;

- Hall;

- Matrosova.

These types of anchors differ in weight, shape and “adaptability” to a certain type of bottom. Let's take a closer look at each variety.

Kurbatov system

It is a clamp made of strong wire and one paw with a slope equal to half a right angle. The extended rod facilitates deep immersion of the metal into the soil or silt. The product is very compact, suitable for small boats.

There are a number of restrictions on the use of this design. The weight of a rubber boat including passengers should not exceed 180-200 kilograms. The boat can be double. It is not recommended to use the Kurbatov system on reservoirs with strong currents and uneven rocky shorelines. It is prohibited to use this type of anchor when the wind speed is more than 6 m/s.

Cat type

One of the most common varieties for small ships. The device can be additionally equipped with an additional weight, which makes it universal and allows you to adjust the weight depending on the load on the vessel. The weight of the structure ranges from two to fourteen kilograms - most often fishermen prefer lighter options. “Cat” can also be used for trawling - searching for gear, sunken objects and other things.

Such anchors are most popular among inflatable boat owners. The design is very simple, and even a novice fisherman can do it. We will consider the DIY manufacturing technique in the next section.

Danforth system

This anchor has an increased holding force, which reduces the scope of its use for fishing and water hunting. Most often used in reservoirs with a sandy bottom.

Maximum holding power is provided by the close placement of the triangular legs, the streamlined shape of the head and the long spindle. When falling down, the anchor cuts deep and is fixed in dense layers of soil far from the surface. However, this property is useless when used on a rocky bottom, with strong winds and fast currents - the Danforth device can be carried away along with the upper layers of sand. In this case, the boat will also drift.

Read How to choose a fishing line and the top best options

A long rod increases the dimensions, which makes storing and using the product difficult. There are about a hundred models of the Danforth system. The weight of the structure is in a wide range: from two kilograms to seven tons.

Hall design

This anchor was invented in the 19th century and made a breakthrough in shipbuilding. It is still relevant in some regions due to the bottom topography. It is made of cast iron, which greatly reduces the cost of production. At one time, this technology allowed the British fleet to further strengthen its dominance at sea. Having fallen to the bottom, the product lies flat and is secured in the ground with one of the teeth. Shovel-shaped thickenings of the paws greatly increase the holding force.

The anchor buries itself very quickly into the bottom substrate, however, it has a large mass and cannot be used in storms above 4-5 points. This design is problematic to make and is only used for relatively large wooden fishing skiffs.

Matrosov's invention

The increased holding capacity is a legacy of Hall’s design, which Matrosov significantly improved and eliminated most of the existing shortcomings. Thanks to its streamlined shape, the product sinks deeper into the ground, and the outgrowths on the paws provide additional stability.

The holding force is increased four times compared to an Admiralty anchor of similar mass. Matrosov’s design does not break out of the substrate even when the vessel turns 360°. Efficiency is the same on clay, sandy and rocky bottoms. Most often, due to the structural features (very closely spaced paws), it is used in the river fleet.

Paw shape

If you analyze the drawings and dimensions of the Danforth anchor, you will notice significant differences in the shape of the lamellas and other elements. The geometry of the paws depends on the angle of attack of the ground adopted by the device for holding the boat. The longer they are, the greater the angle of attack. The length of the legs can be from 55 to 70 percent of the length of the anchor spindle. This requirement must be met if no more than 35 percent of the surface area of the paws is located behind the axis of rotation. If this figure is greater, then their length can be 55 percent or more.

There is no general consensus regarding the most advantageous Danforth anchor claw shape. Reviews from owners of boats and boats are sometimes contradictory. According to scientific calculations, the most advantageous is the triangular shape. In this case, for their manufacture, thin-walled sheets of durable steel grades alloyed with chromium and other impurities should be used.

Types of anchors

Anchors have been used by all those floating on water for thousands of years, and thousands of their designs have been invented. But in practice, few have taken root - the anchor is extremely important for the safety of navigation.

The types of currently common anchors and the names of the main parts of the anchor are shown in the figure:

Types of anchors for large and small vessels

If a cable or chain is attached not to a freely dangling ring - an eye - but to one fixed rigidly on a spindle, or to a bracket, rotating or tightly fixed, then this is no longer an eye, but a butt of the anchor. Very often, a small eye or butt is attached to the trend, and a thin line - buirep - with a buoy floating on the surface of the water is tied to it. Pulling on the buoy rope most often manages to free the stuck anchor, but if you pull on the cable/chain, it only clings more tightly.

Note : what M means, see below.

Proportions of the Admiralty anchor

The Admiralty anchor has been known since the Stone Age: then it was made of wood with a stone stem. This anchor is reliable on any bottom, but, firstly, it is heavy, because... realizes no more than half of the potential holding force, and is cumbersome. On old sailing ships, it was raised and hung from special powerful beams, called crambols, sticking out obliquely from the bow of the ship. Secondly, in shallow water or when the water level drops (for example, at low tide), the ship can sit with its bottom on the anchor horn sticking up. You can partially get rid of the bulkiness by making the rod removable. The great advantage of the Admiralty anchor is its simplicity of design and proportions, verified over centuries, see fig. on the right, and suitability for vessels of any displacement, including toy boats. To obtain the dimensions of an Admiralty anchor of less weight, straight lines in Fig. just extend to the left. A serious drawback is weak tenacity: in order for the rod to tip the anchor into the correct position and the paw to bite into the bottom, you need to pull the cable/chain quite hard and drag the anchor. The Admiralty anchor can be recommended for boats equipped with sails and going out into deep water.

The Porter (more precisely, Porter-Trotman, in the figure) and Northhill anchors are modifications of the Admiralty one. Rarely used, because are not without its disadvantages, giving in return few advantages. Hall's anchor is a truly brilliant find: Hall came up with the idea of entrusting the task of the rod to the loose arms with a skirt at the bottom, and to ensure full grip of the anchor, he made them rotatable. Hall anchor for ships approx. from 5 tons of displacement has no disadvantages and currently absolutely dominates the fleets. But it is also applicable for inflatable boats without sails: the too small ratio of weight to holding surface in this case is compensated by the low friction of the boat with the water. Therefore, we also give standard proportions of the Hall armature (see figure), for comparison with amateur samples.

Hall anchor drawings and dimensions

Note: the Hall anchor is a technologically complex product. For its reliability, the location of the centers of gravity of its components is also important, which is also standardized.

Letter M in Fig. with types of anchors denotes the Matrosov anchor (see figure). In the vessel's displacement range of approx. 1-100 t it turns out to be more reliable than the Hall anchor with a lower mass; especially on weak bottom soil. The Matrosov anchor is interesting to us because its method of creating holding force is fundamentally different than that of the Admiralty and Hall anchors: the Matrosov anchor is actually one-legged. This method allows us to create absolutely tenacious anchors of extremely low mass for very light ships, which is what we need.

Drawings and dimensions of Matrosov's anchor

Matrosov’s idea was brought to its logical conclusion by Danforth, who designed an anchor in which the ratio of mass to holding surface is theoretically equal to... 0! That is, the Danforth anchor (see the next figure for its drawings and dimensions) can, in principle, be made even from paper, as long as it does not get wet and break. But - up to a certain upper limit of the vessel’s displacement; This is where the square-cube law comes into play. For those who know something about mathematics: Danforth realized what part of the curves on the graph of certain characteristics of the anchor can be approximated by a straight line, the derivative of which, as is known, = 0.

Drawings and dimensions of the Danforth anchor

The Danforth anchor dominates small shipping as much as the Hall anchor dominates large shipping. To recalculate its dimensions to a smaller mass is simply the same as for the Admiralty: we do linear extrapolation, and that’s all. A fork anchor is theoretically the same as a Danforth anchor, only more technologically advanced for self-production and more reliable on a rocky bottom: it is more difficult to break one powerful paw than one of two of the same total area.

Note: Matrosov and Danforth anchors are often supplied to large ships as spares or werps (taken out on a boat).

The plow anchor is also theoretically “zero” and has no equal in terms of specific holding surface area, although its tenacity is approximately the same as that of the Admiralty. Therefore, patented plow anchors of various types (Delta, Bruce, etc.) are quite popular abroad among sailing yachtsmen on ocean yachts. But storing an anchor-plow on a ship is extremely inconvenient. The only suitable place for this is the bow roller, and even then, the plow anchor, in addition to the tightly stretched anchor chain, has to be tied down with three more cables: an upper one and a pair of side ones, so that the hole in the hull is not plowed. Anyone who has gone out to sea, even with a bull on an elastic band, will read about this fashionable fad and just shake their head: what if the plow anchor needs to be quickly released at night during a storm? What will happen then? We are interested in the plow anchor because it is the origin of the mushroom-shaped anchor, which is undeservedly little known to owners of PVC boats, see below.

Note: in large-scale shipping, fire guards are often placed on plow anchors - ships without power, assigned for a long or eternal stay in a certain place in the water area (floating warehouses, berths, guard posts, barracks, prisons, etc.).

About Kurbatov's anchor

Among fork anchors, the Kurbatov welded anchor is popular among domestic amateurs (see figure below). It holds a boat well with a displacement of approx. from 300 kgf on our usual bottom soils: sandy, clayey, silty. In the northern United States and Canada, where the bottom of river streams is often rocky, the Trident anchor with a 3-prong double-width fluke (bottom right in the figure) has proven to be more reliable. The second thing that can be said about Kurbatov’s anchor is that it doesn’t hold 1-2 seater inflatable boats on calm water in windy weather; it crawls along a weak bottom. Since in this case the matter is corrected by the weight (see below), it remains to be assumed that the low weight of this anchor has an effect. Danforth developed the theory of a zero-mass anchor, but its actual weight still affects the properties of practical structures. And this can be very useful specifically for the anchor of a PVC inflatable boat, see below.

Drawings of the Kurbatov anchor and the appearance of the Trident anchor

Optimal rod length

When producing a product at home, it is very important to choose the correct rod length. The description of the Danforth anchor was compiled by intelligent engineers who paid special attention to this detail, understanding its importance.

If the rod is too short, the device does not “bite” into the ground. It simply slides along the bottom as the boat is carried away by the current. It is calculated that the length of the rod must be at least twice the distance between the geometric centers of the arms of the device for holding the boat.

We make our own anchor for a PVC boat. Danforth anchor using an angle grinder and a drill

A little earlier we already told you how to make an anchor for a PVC boat with your own hands without using any tools other than a drill. Then we were talking about making a simple suction cup anchor from an old brake disc. This time we’ll talk about a more complex unit - the Danforth anchor.

How to make a Danforth anchor at home with your own hands has already been told many times, shown in the video and in the drawings. Why else talk about this? But why. In all articles and video reviews, welding is required to create it. Our task is to assemble the anchor without using a welding machine, making do with only a drill, a grinder (or a hacksaw), a pair of ordinary heads for tightening the nuts, and our own hands.

DRAWING OF DENFORT ANCHOR

This time we will be guided by a simple drawing of an anchor. However, a drawing is a big word, let’s make do with a hand-drawn sketch indicating the main dimensions, in this case this is more than enough.

MATERIALS AND TOOLS REQUIRED

Materials:

- aluminum pipe 30x2x600 mm (it can be steel, and the cross-section can be changed, we just happened to have just such one on hand);

- steel sheet minimum 200x200 mm (preferably 3-4 mm);

- bolt 8x60 = 1 piece;

- nut M8 = 3 pcs (preferably self-locking);

- body washer D8 = 2 pcs;

- bolt 5x35 = 2 pcs;

- nut M5 = 2 pcs;

- eye nut and corresponding bolt = 1 piece (if you fasten the rope differently, you can do without it);

- a small ring (preferably, but not necessary; in combination with the lower mount, it is used to remove the anchor when hooked).

Tool for making an anchor with your own hands:

- drill;

- grinder (you can get by with a hacksaw, but it will take more effort and time);

- head 13 mm = 2pcs;

- extension cord L-125 = 2 pcs (you can also use something else, for example, a large slotted screwdriver, you will understand later).

ANCHOR MANUFACTURING PROCESS

First, let's make the paws for our anchor. To do this, I recommend drawing them first on a piece of cardboard, cutting out a stencil, and using it, a little later, we will cut out steel ones. In the meantime, for “trying on”, it’s better to use cardboard. Paw shapes - which one you like best.

Next, we take our pipe and cut it into two parts - 200 and 400 mm. In the shorter one, we make two cuts in length and width in accordance with our cardboard model of the paw. In the center we cut out a segment 34 mm wide (i.e. slightly larger than the diameter of the pipe) and ½ the diameter deep (a little deeper can be). We drill 5 holes - 1 in the center for the bolt securing the eye nut and 4 pieces with a diameter of 5 mm for attaching the anchor legs (in principle, 2 are enough, one on each side). You should get the following result.

After this, we cut out the legs from metal, insert them into the slots, and drill holes in them in accordance with the holes in the tube.

Take the second part of the pipe (400 mm). At one end of it we make oblique cuts so that it can rotate in the central cut of the short tube, but in such a way that there is enough area left for the hole for the M8 bolt, which will act as the axis of rotation. At the other end we simply drill holes.

Now it’s time to assemble the entire structure. We fasten the eye nut (the anchor rope will be tied to it).

We make an axis of rotation - twist the bolt, nut and washer in this way.

We insert the pipe into the pipe, install the axle and fix it - screw the nut almost to the end, but do not tighten it, throw on the washer and now tighten everything with another nut. This is where you will need sockets and extensions (if there are no extensions, you can use a slotted screwdriver of the appropriate width). The end result should be something like this.

Now all that remains is to screw on the anchor arms and plug the ends of the tube with wooden plugs, they will eliminate any play in the arms and that’s it.

With this method of tying, it is advisable to install a weak ring (from a bunch of keys) at the end of the handle and tie a rope. However, there are different fastening methods that ensure the anchor is removed when hooked; choose the one you like best.

Of course, it turned out to be a little unpresentable and not too neat, but we didn’t think about beauty. The task was to try to make a PVC anchor for the boat with our own hands, specifically a folding Danforth anchor, without using a welding machine, only using a tool available to everyone. It seems to have worked out.

How to use an anchor correctly?

A person who has only recently purchased a boat and is just planning his first trip to sea on it may mistakenly believe that the mooring process is an extremely simple matter. We can say with confidence that such an angler will be taken aback. Anchoring is by no means a simple matter, which requires a certain dexterity, skill and knowledge from a fisherman or yachtsman.

First of all, it is necessary to securely fasten the end of the rope to the anchor ring. For these purposes, it is advisable to use a special maritime unit. Otherwise, you may lose your device.

Directly near the anchor feet there is a second ring. You need to attach a rope with a buoy to it. The length of the cable must be greater than the depth where the boat is moored, otherwise the buoy will sink. This buoy will help “save” the device in case the anchor rope breaks or gets caught on plant roots and stones.

Having reached the place where it is planned to stop, the holding device is thrown overboard. Over a certain period of time, the boat will be carried away by the current and the wind until the anchor reaches the bottom and “bites” into it. Then you can tighten the rope.

With your own hands

To always use a reliable and convenient anchor, it is better, and most importantly, cheaper, to make it yourself. A careful study of the manufacturing instructions shows that the process itself is quite easy and does not take much time. And it is not at all necessary to be a professional in this matter.

Making a simple collapsible anchor

You will need the following devices:

- steel tube with a diameter of 25 mm and a length of 270 mm;

- bushing and nut 25 mm, M12; ;

- steel strips – 2 pcs. (a=260 mm, b=40 mm, c=4 mm) and 2 pcs. smaller sizes;

- metal rings – 2 pcs.;

- solid lead (molten) - about 2 kg.

A sleeve must be welded to the end of the tube. Strips of steel, the edges of which are pre-treated with sandpaper, are useful for making paws. Two more strips of steel are welded to the ends of one arm to prevent the anchor from twisting. The paws are put on the rod and the nut is sealed.

Rings are welded onto the nut and to a pre-made hole at the other end of the anchor for ease of assembly and lifting the anchor from the bottom.

To increase stability on the water, the anchor can be made heavier by pouring lead into the rod.

The folding model of such an anchor is considered the most optimal choice of anchor for PVC boats.

Welded homemade Kurbatovsky anchor

Simple and convenient, for self-production we will use:

- metal rod 12 mm long;

- strips of steel 3 mm thick;

- wire with a diameter of no more than 8 mm.

First, a spindle is made from wire, onto which strips are welded (on top) and can be tied. They will ensure paw rotation and good “adhesion” to the bottom. The ends of the spindle are welded with a strip of metal

If the bottom is quite rocky, then you can use some kind of blank instead of the Kurbatov anchor.

Homemade cat anchor

The most common type for 3-4 meter boats are cats, which are classified as folding anchors.

The position of the paws can be changed from lower to upper by moving the coupling along the spindle. For ease of transportation, the anchor arms are fixed at the bottom using hinges.

Such cats are the best option in calm weather. In case of strong gusts of wind, it is better to make such anchors heavier.

Homemade pyramid-shaped anchor

The first method of making an anchor requires a pyramidal shape and solid lead.

The mold is usually made from sheets of metal that are bent into two halves. Then they are fastened together with wire.

The mold is inserted into a prepared hole in the ground and filled with molten solid lead. A wire eye is inserted into the not yet hardened lead (for fastening the anchor).

Lead can be reused from old car batteries.

The second method requires steel plates of different sizes.

They are placed on the bolt so that the smallest one is on the bottom. To tie the rope to the anchor, just weld the ring in place of the head. Functional because you can quickly change the mass of the anchor.

How not to sink an anchor?

A fisherman cannot know for sure what the bottom of a reservoir is. Therefore, the possibility of losing an anchor is quite large.

To avoid this, you need to follow these recommendations:

- — you cannot throw out an anchor without first securing it to the trend;

- — it is necessary to have a buoy;

- — a snagged anchor can be pulled out by gently pulling it by the buoy rope.

The cat's anchor has a very high probability of being lost due to the rocky bottom of the reservoir.

This can be avoided in two ways:

It is necessary to tie the buoy rope together with the buoy to the junction of the legs and the spindle, and then carefully pull the anchor by the buoy rope. It is necessary to install another ring (made of soft material) on the main one. First attach the rope itself to the junction of the paws and the spindle, leaving half a meter in length

Read Recipes for bream bait for different fishing conditions

Then tie it to an additional ring, which will open and the anchor will be pulled out, as in the first method.

Advantages of homemade anchors over factory ones

Currently, an increasing number of fishermen make their own weights, floats, and even the fishing rods themselves.

Do-it-yourself anchors are also no longer news.

This is due to the following reasons:

- -cheaper than factory ones;

- more reliable (you cannot always guarantee that you bought a high-quality and original product and you were not deceived).

Disadvantages inherent in the design

Any engineering solutions have their drawbacks. You can already see from the photo of the Danforth anchor some flaws in its design. These should be discussed briefly so that the reader can weigh the pros and cons when choosing a boat holding device.

Perhaps one of the main disadvantages of small anchors of this type is their unsuitability for use on a bottom covered with large stones. An attack by such a device on a rocky bottom always remains ineffective. Small categories of Danforth anchors (4 kg or more) are strongly carried away by the current. Thus, the device is lowered in a completely unexpected place.

And the other side of the coin... Even a Danforth anchor that is insignificant in weight and size will secure a PVC boat well and reliably if the bottom is soft and muddy. Working only with your hands, such a device is quite difficult to tear out. In this case, the small boat will sway violently and may even capsize.

And yet the cat is an anchor!

It's time to remember the cat anchor and at the same time the mushroom anchor, because... they are also interconnected. The path of origin of the mushroom anchor from the folding cat is illustrated by the left part of the trace. rice. The good thing about a mushroom anchor is that, with minimal dimensions and complete safety for an inflatable boat, it holds it on a very, very weak bottom - deeply silted, floating fine sand, etc. And also because its size and weight are smaller than other anchors, depending on the length and displacement of the vessel. However, a mushroom-shaped anchor for a marshy bottom must be equipped with a butt on the trend: it is impossible to pull it out by the eye or butt if it gets pulled into the ground without scooping it up with the side.

From grapple anchor to mushroom anchor. Drawings of a folding mini cat anchor for a PVC boat

You can make a mushroom-shaped anchor from the bottom of a household gas cylinder; Already an anchor from the bottom of a 5 liter cylinder reliably holds a 1-2 seater PVC boat. The bottom of the cylinder is cut off where it meets the vertical walls (the tangent slope is the same as that of the Admiralty anchor - 40 degrees). 3-4 holes with a diameter of 30-40 mm are cut into the bottom so that the soil is pressed through them and does not clog the anchor blade.

The spindle of a mushroom-shaped balloon anchor is made from a piece of steel pipe with a diameter of 40-60 mm. Its length for 1-2 seater boats is from 200 mm; for 3-4 seater – from 300 mm. The butt of their bent 10 mm reinforcement is welded to the top of the spindle. And to the trend - a 6-8 mm shank. For complete reliability of such an anchor, the spindle is filled with lead at any bottom.

The evolution of the grapple anchor can be taken along a different path, as exemplified by the drawings of a folding mini-anchor for a 1-3-seater PVC boat in the rest of the picture. Its method of creating holding force is completely unique: when dragged, this anchor turns, screwing into the bottom soil or clinging to stones with its paws. For greater reliability, it is advisable to weld its spindle from pipe sections and fill it with lead. The tenacity of this anchor is not great: it needs to be wired about a meter to secure it properly. But the folded mini-anchor can be carried in your pocket, and it is a non-losing anchor: a tug on the anchor-cable is enough for its stuck paw to come out of the crack or for the anchor pulled into the swamp to go up (vira, as a sailor would say).

Cat made from scrap materials

The grapple anchor has one more advantage: it can be made from scrap materials. Specifically, from a couple of crooked fragments or scraps of branches for the paws, a stone of a suitable size and shape, and another piece of a crooked branch or flyer for the spindle. The paw branches are tied crosswise, a stone is tied to the crosshair; then add a flyer or a spindle branch to it. There are cases where people survived in extreme conditions thanks to a homemade grappling anchor made from scrap materials.

Note: however, do not forget that the inherent defect of any grapple anchor is that the boat can sit on its paw with the bottom!