Vladimir Sokolov | August 13, 2021

We buy boats with motors for a variety of purposes. For some, a motor boat is a means of transportation from point A to point B. And at the same time, it is not particularly important at what speed the pictures of nature will replace each other along the route. We go on a glider - and it’s great, we don’t need anything else. In general, we are content with what we have, not at all puzzled about how to add speed and, as a derivative, get an increase in efficiency as a bonus. But there are those among us who want more.

Of course, not immediately, but after using the kit. After driving for some time on the stock one, i.e. store kit, they begin to improve something on their ship. As a rule, it all starts with tuning the boat itself - adaptation to specific travel conditions, fishing conditions, in order to add comfort both when moving through the water and when the ship is at anchor. I have already reported on many of these developments on the pages of our magazine.

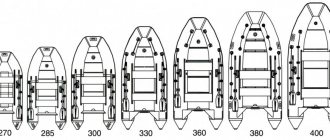

I have probably considered all aspects of such an upgrade, but have not yet touched directly on boat hulls – motors – propellers. I'll start with boats, because some models may require some intervention, although this time we will do without the use of scissors and glue.

The fact is that not all manufacturers to this day pay due attention to the contours of their boats. We will now talk about boats with a hard bottom, which may often require intervention, and this intervention is usually not so radical compared to boats equipped with a low-pressure inflatable bottom.

Checking the keelson position

The first object of our meticulous inspection will be the inflatable keelson and its installation on the bottom sheet. If the manufacturer glued the keelson to the wrong length of the bottom - shorter or, conversely, longer - either a dip or a hump may form in front of the transom (and in photo 1 - both). At the same time, the photo shows not the most striking example; sometimes it is much more serious. I wouldn’t dare call it a defect, because it doesn’t really interfere with swimming and, if it does affect controllability and safety, it’s only slightly.

But if the boat is used intensively, then a lower speed will lead to higher fuel consumption, which, given current gasoline prices, can already be noticeable for the family budget. If it is not possible to contact the manufacturer directly with such a defect (especially since some of them justify a shortened keelson by the need for easy access to the drain valve, located, as a rule, at the lowest point on the bottom - photo 2 ), then the issue can be resolved on your own and with your own hands.

To eliminate the hole that appears in front of the transom, you can go in different ways. Let's look at the two simplest ones both in terms of work and materials. First option: since we will straighten only a small section of the keel, approximately 150 - 200 mm, different plastic profiles will fit into this area for support.

On the boats I've worked with I've installed a piece of gray pipe for plumbing work, but white plastic pipe for air ducts will also work. In photo 3 it is designated as a “forming cylinder” and highlighted in red. Just before going to the store, you need to accurately measure the distance from the bottom surface of the floorboard to the bottom, but taking into account how it should ideally stand.

The purchased pipe must be of such a diameter that a small, 100 - 150 mm, tip of the keelson fits inside it and so that the installed aft section of the floorboard reliably forms the keel line with the help of this pipe. If a valve drain mechanism is installed on the transom, then a cutout should be made in the top of the pipe that matches what is in the floor section. This plastic device does not need any additional fastenings; it is already securely fixed by the aft section of the floorboard.

This design is easy to manufacture. It does not interfere with the transportation and folding of the boat and is installed in the boat before installing the two aft sections of the floorboard. But it helps only if the bottom is tensioned well enough and such a depression is observed only in the keel area.

In this regard, I cannot help but mention that in one of its Viking PRO models, in order to impart the necessary deadrise, it places a similar keelson design already, as they say, in the drain (photo 4) , only shifting the drain device slightly to the side (photo 5) , so that the keelson of the new design does not overlap it.

If there is a depression along the entire line of connection between the glued bottom and the transom, then in this case the struggle will be much more difficult and simply using a pipe will not do. This is the second option to solve the problem. And it is supposed to be a rigid insert made of sheet plastic. It can be made, for example, from foamed PVC or a piece of fiberglass 3-5 mm thick, depending on the rigidity of this composite. This panel (or two parts of a common panel), placed between the keelson and the bottom, will maintain the shape of the bottom from the inside and will be able to completely or significantly remove the dip along the entire gluing line of the bottom sheet and straighten the hump, significantly improving the contours of the vessel.

This kind of work can be done in the kitchen, having the simplest set of tools at hand. You just need to take the exact dimensions, transfer them to a sheet of cardboard, cut out a template from it and fit it strictly in place, without gaps along the seam on the cylinders. I made similar inserts from sheet fiberglass 2 - 3 mm thick, cutting out a “wing” of this shape (photo 6) . This design is suitable for both cases: when you need to remove both the hole and the hump in front of the transom. The only difference was the height of this “wing”: for a hillock it is, as a rule, 200 - 300 mm larger.

If for these purposes you use foamed PVC, which has a noticeably lower hardness, it makes sense to chamfer the insert along the front and side edges so that there are no noticeable protrusions from it on the outer surface of the bottom. The insert is transported separately and is installed in its place only at the final stage of boat assembly before installing the solder covering in the stern.

I note that in some cases the use of the insert can be combined with the installation of a cylinder to rest on the keelson.

Boat speed concept

Despite the detailed presentation of the factors influencing speed, it is necessary to consider the concept itself. Boat speed is a variable parameter that depends on many factors (engine, propeller, hull, etc.). Among users, models with casings made of aluminum, plastic and steel are in particular demand. The materials provide not only the strength of the swimming apparatus, but are also responsible for the quality of the bottom sliding along the water surface.

- Fiberglass. It polishes well and is light in weight, thereby increasing the speed of the boat. The downside is the serious susceptibility of the equipment to shocks and deformations;

- Aluminum. This is a true standard of modern shipbuilding. The material is lightweight but more durable than plastic. The same applies to duralumin models. It does increase speed due to its weight, but not as well as fiberglass;

- Steel. The most durable, but heaviest material. It is not used on high-speed boat models, and is more often found on ships of older times.

It is also worth paying attention to the area in which the water apparatus is used. For example, river vessels often move at a speed of 20-30 or 50-60 km/h. Sea ships move at an average speed of 36 knots (approximately 66 km/h). Sports models are capable of surpassing sports cars or motorcycles, accelerating to 200 km/h or more.

Cruising speed

The cruising speed of a motor boat is an indicator of traffic intensity with minimal fuel costs, and it is always lower than the maximum movement capabilities of a watercraft on water. The average operating range of each installed motor determines this factor. To take a closer look at the cruising speed and compare it with the maximum, users simply calculate the number of kilometers traveled per 1 liter of fuel. As for yachts with sails, the concept of average speed is more typical for them, since they often move on tacks.

Maximum boat speed

The maximum speed of a boat on the water is driven by the engines operating at the limit of their capabilities. As a result, fuel consumption while driving increases noticeably. Engine power is not the only factor influencing maximum performance, as it is necessary to take into account the material of the boat's hull, weather conditions and much more.

You may be interested in: Electric motor for a boat: how to choose, characteristics, operating features

Screw selection

The next step in a set of measures to improve our watercraft is selecting the right propeller for the motor. The procedure is quite complicated, especially in our conditions. The fact is that it will require additional equipment in the form of a GPS navigator to measure speed and a tachometer to correctly measure engine speed.

But that's not all. Unfortunately, not all commercially available screws meet the stated parameters. That is, the step numbers are the same, but when checked on the so-called “step slide” (photo 7), a deviation is detected, sometimes quite significant. And, worst of all, if the pitch from the root to the edge of the blade decreases (photo ), this leads to the fact that, due to the large difference in the speed of flow on different surfaces of the propeller, cavitation begins much earlier than the calculated values - at approximately 3200 - 3500 rpm

The resulting bubbles of water that has already begun to boil at reduced pressure lead, starting at speeds of slightly more than 34 - 36 km/h, at the first stage to a noticeable loss of screw stop. And in the future - damage to the edges and blades of the propeller due to increasing shock loads. And this process has an avalanche-like character.

Sometimes you hear from colleagues that a seemingly good, well-glued boat accelerates only slightly over thirty, and no manipulations with the engine suspension or movements of the crew and cargo in the cockpit can change anything. Some even have the feeling that the screw is simply turning on the bushing, which in the vast majority of cases is not the case.

What's the matter? But the thing is, if the boat has already been finished, as was described just above, it’s most likely in the propeller. And sad as it is to say, such screws with broken geometry are found on motors “from the store”. Quite a long time ago, when faced with the problem of insufficient speed on a friend’s kit, we tried seemingly all options, but we couldn’t even sin with a stock propeller. However, we decided to still check the screw on the step slide.

And - lo and behold! — the “native” propeller from a well-known manufacturer showed not quite adequate figures during measurements. And what’s most unpleasant is that along the blade from root to edge these indicators changed in an incomprehensible sequence (photo 9) .

There were no propellers with a guaranteed and proven pitch that were easily accessible, so we decided to bend the blades of this one. It’s good that there are specialists on earth who do this kind of work. And not only on earth, but also here in St. Petersburg. We turned to one of them, known on the web under the nickname Almai Together we figured out what could be done besides bending it.

A few days later we were already putting the screw in place. And after this propeller tuning, the boat ran almost 12 km/h faster. Which I think was worth all our troubles. The screw began to work exactly in the mode for which it was intended.

Over the past few years, I have seen screws of varying quality. Among them there were simply ideal ones, but there were also very strange ones that should not have gone. The discrepancy from the stated parameters was sometimes more than 4 inches. This is clearly too much! I will not place responsibility on either the manufacturers or the sellers, but I will only say one thing: it is better to check the propeller on a walking slide if there is even the slightest doubt about the speed of a boat that has already been completed.

The selection of a propeller usually begins with checking the geometry and workmanship of the propeller. And only after that they switch to water to measure the speed and maximum speed developed by the motor with this propeller. I usually use this algorithm for this process.

There is one person in the boat and a minimum load. The speed measurement is what is visible in the GPS , and not the maximum speed later on the shore. And the maximum revolutions that the tachometer showed during these runs. It is better to conduct races in calm waters and where there is no current, otherwise the final picture will noticeably change and the necessary accuracy in measurements will not be achieved.

If, with the selected load, the tachometer shows exceeding the maximum speed declared by the manufacturer, or a “cut-off” is triggered on the motor, then the propeller is conditionally “light” for this load. Naturally, you can use such a propeller, but you should keep in mind that driving the engine above the stated speed does not really prolong the life of the engine. Although, having obtained this result on a boat with a minimum load, it is worth trying this propeller with the boat loaded to the maximum - as is usually used when going, say, fishing. If in this case the motor “twists”, then it is worth changing the screw to an analogue one in shape, but in increments of 1 inch larger.

Unfortunately, screws with fractional pitch values have somehow not taken root here, although such diameter values are found quite often abroad. But by installing a larger pitch propeller, you should not expect an increase in speed, especially on a loaded hull. On the “light” side, most likely, an increase will appear, although this depends on many values and provided that there is an accessible opportunity in the workshop to change the pitch of the propeller, its diameter, the disk ratio, and the shape of the blades. Now we are talking about how you can tune it without significant alteration.

The practice of using various screws shows that by replacing similar-shaped screws with different pitch values, we can add or remove maximum speed. The calculation is approximately this: each added inch “removes” an average of 200 to 350 rpm.

However, I repeat, replacing a propeller does not always lead to an increase in speed. But by installing a new propeller and selecting the economical mode, you can save quite a lot on fuel. Just last year, a friend’s boat originally had a 13-inch pitch propeller on a 4-stroke Yamaha 60 . With it, the boat easily accelerated to 55 km/h, while the engine turned a maximum of 5200 rpm, i.e. the screw was “heavy” for this case.

When the crew with fishing equipment came on board, the speed decreased noticeably and the engine speed did not rise above 4800. After replacing the propeller with an 11-inch boat, it easily reached the same 55 km/h, but at 5900 rpm.

But when the crew went on a long voyage, choosing an economical mode of about 4800 - 5000 rpm saved more than 25% of fuel. Provided that we traveled under a hundred kilometers, the savings were already quite noticeable. And the engine worked in a more gentle mode under load. This all, however, applies to a large case, but for small ones the savings will be a little less, but if someone goes on some kind of long autonomous trip, then this will still be relevant.

Increasing the speed of inflatable boats

In PVC inflatable boats, the speed is greatly influenced by the level of pressure in the cylinders. It must be constantly maintained, not forgetting that after prolonged contact of the cylinders with cold water, the pressure inside drops due to temperature changes. Maintaining the pressure level becomes even more important in cases where the boat has poor-quality air valves or problematic seams.

There should be no wrinkles on the inflatable boat due to lack of air, otherwise this will negatively affect the speed of the craft.

Cylinders and keelson should be inflated a little more than normal to compensate for the natural loss in pressure. Also, by filling the cylinders and keelson with more air, you can get rid of the common problem with playing payola in the waves.

In order not to worry about cylinders left in the sun, first find out the maximum permissible pressure level for your PVC boat. It would be great if the boat has a special bleed valve installed.

Replacing the aluminum propeller with a steel three-blade version, which will provide higher performance, will also help increase the speed of the boat.

Author of the article: Vitaly Leonidovich Ivanov, 2021.

Installing the motor on the transom

Having completed the selection of the propeller, speed lovers usually do not stop there. And the next step in setting up the kit is choosing the optimal height for mounting the motor on the transom. This is generally a simple matter, but some physical features of the process should be kept in mind. The engine manufacturer's recommendations are to install it so that the automatic transmission (anti-cavitation plate) is at a level from 0 to 50 mm under the extension of the keel line. These recommendations apply primarily to hulls with “deep V” contours.

If the deadrise is less, then such recommendations should be approached with caution. Most PVC boats have contours close to flat-bottomed, when the deadrise at the transom does not exceed 5 - 7 degrees. Therefore, you should not raise the motor very high in order to avoid air leaks and snags when the propeller suddenly unwinds and begins to work almost in foam.

This phenomenon is harmful to the gearbox. When lifting the motor on the transom and rolling it lightly in the boat, you should not abuse the lift, and having received the first grip in a turn, it is better to lower the motor by 5 -10 mm and fix it in this position.

I would like to especially note that those who will be lifting the engine on their own should keep in mind that in the upper position the spacers must be especially carefully fixed, using overlays on the transom - both the outer one made of plywood and the inner one made of plastic, lifting them up to the clamp.

Motor leg length (deadwood)

An important procedure when increasing the speed of the boat is to adjust the location of the motor in relation to the transom, and subsequently change the length of the deadwood.

As you know, the higher the propeller itself is located, the lower the resistance of the deadwood boot will be, and therefore the speed will increase. If there is no possibility of special adjustment of the screw height, use spacers under the clamp.

However, on the other hand, it is worth remembering that a propeller raised too high will capture air during turns and when more or less noticeable waves pass, and this will negatively affect the speed and may even become the root cause of a small boat capsizing.

Thus, through experimentation it is necessary to find a compromise and ensure the optimal deadwood length. The best performance of the propeller is achieved in a position where its axis and gearbox move parallel to the surface of the water.

Motor angle

And one more tuning unit that can slightly increase the speed. I mean varying the angle of the motor. Usually, given that all boat transoms are installed in a very small range of angles, the motor is operated on the second, or at most, on the third “hole”. If the entire set of settings for the motor suspension and propeller selection has been completed, then by tilting the motor one more “hole” you can get a very pleasant increase in speed. But this addition will appear only under one condition - ideal hull hydrodynamics and maximum displacement of the skipper to the stern.

All of the above are not recommendations for preparing a boat for some kind of sports racing, but only optimization of your kit. Although, perhaps, this is the first step in that direction...

Engine and propeller condition

If you want to achieve the highest possible boat speed, the engine must always be in perfect working order. In addition, do not skimp by buying cheap motor oil and fuel.

The propeller should also not have any defects, such as chips that often form on the edges of the blades. Also, the speed is influenced by the parameters of the propeller itself, its dimensions, and the bending of the blades.

Ways to measure boat speed

The speed of a motor boat is measured in knots, and this rule applies to vessels of any type. A knot is equal to 1 nautical mile per hour, a unit of measurement that is completely independent. The history of the appearance of this unit appeared as a result of measurements using a sector log.

The speed was calculated by a measurer who gradually lowered a line into the water with knots tied on it every 50 feet. A special float or hydrosail was attached to the end. For 30 seconds, the number of nodes passing through the measuring arm during movement was recorded.

You might be interested: Silver boats - types, advantages and characteristics

In countries where the measurement system is metric, the usual kilometers per hour are used to calculate boat speed. A knot is equal to 1.852 km/h. To calculate the traffic intensity from knots in km/h, you need to multiply the speed in knots by 1.852. At the moment, almost every vessel is installed with an electromechanical device that approximately recalculates the number of propeller revolutions in average weather conditions. On more modern models, navigation instruments show more accurate numerical values.