What can a boat motor be made from?

The motor can be made in various ways, the main thing is to choose a suitable base and additional parts. An engine from a trimmer or walk-behind tractor, as well as a screwdriver, can be used as a base. A boat motor made from a chainsaw has the best characteristics.

From the trimmer

The trimmer boat motor saves fuel and has a transparent tank. The propeller (homemade propeller) is made of duralumin. The propeller blades are bent up to 10 mm, the edges are carefully sharpened. It is put on in place of the trimmer head. To prevent the propeller blades from damaging the boat during operation, use a ring attachment. The motor shaft and propeller are connected by adapters. The starter is removed from the lawnmower. The motor from the trimmer is made according to a drawing prepared in advance.

From a screwdriver

If you use a cordless screwdriver, you will get a good homemade engine. For manufacturing, it is better to choose a device with a voltage of 12 V. The process of making an electric motor for a boat with your own hands using a screwdriver:

- The propeller must have a lifting mechanism, so it is attached to the engine transom and secured with frames and plates.

- Clamps are equipped with rings. A tube with a shaft is laid through them. The shaft is made of steel wire or rod.

- Bearings are pressed inside the tube. They will provide the steel shaft with easy sliding.

- To reduce the speed of the electric motor, install a gearbox from an angle grinder. The upper part of the shaft is clamped in the screwdriver chuck.

- The propeller is made of stainless steel, the thickness of the sheet is 2.5-3 mm.

From a walk-behind tractor

From a walk-behind tractor starter you can make a motor for an engine. To assemble a four-stroke model, a simple fuel system is used, but the water pump must be of high quality. The sternwood is removed from the old boat engine. The fuel pump is installed above the carburetor so that it does not come into contact with the rocker arm, and secured with clamps. The crankshaft is mounted above the top gear. A water pump is installed under the deadwood. If you install springs, the lower rod will work freely.

You will find many other interesting homemade products from scrap materials here.

What are homemade boat motors made from?

Many fishermen have faulty electrical or gas equipment in their storage room or garage. If the motor in it is working properly, then such a device can be modified to fit an existing boat. In some cases, it is even cheaper to purchase a new screwdriver or brush cutter and modify the device than to buy a boat motor. It is the financial issue that pushes numerous “left-handed” and “home-made” people towards unique developments.

- To make a homemade electric boat motor, you will need a cordless drill or screwdriver. In this case, the fisherman will have to solve the following problems.

- Unfortunately, the capacity of the standard battery will not be enough for carefree sailing, so you will have to take a 12V car battery on board. Accordingly, the device must also operate at the same voltage. As for power, an electrical device that produces more than 300 W can handle a light rubber boat.

- The rotation speed of the screwdriver is quite high, so it is necessary to install a reduction gear.

- You also need to purchase or make your own drive shaft and propeller.

A homemade electric boat motor will operate silently, which is very important for good fishing. In addition, replacing a failed electric motor will be cheaper than repairing a boat engine.

- Gasoline engines made for a boat with your own hands can significantly increase the fishing area. These can be power units from chainsaws, lawn mowers, walk-behind tractors, etc. The choice of installation depends on the size and design of the vessel, as well as which of the devices is available.

- Trimmers require the least modifications. They look like they were made to be installed on a fishing boat. It is enough just to install a propeller instead of a reel with fishing line and the boat motor from the trimmer can be tested on a nearby body of water.

- Engines from a chainsaw, motorcycle or walk-behind tractor will require more intervention by skilled hands. Requires a bevel gear from an angle grinder, a shaft and a propeller.

All homemade boat motors require a special device for attaching to the side of the boat. It's one thing when the boat has a transom to which you need to attach the engine. It is somewhat more difficult to secure the power unit on a regular elastic band with inflatable sides around the perimeter.

Characteristics of outboard motors

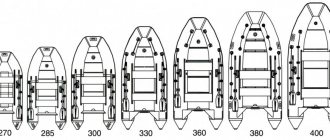

First of all, you should pay attention to the size and power of the engine. To prevent the stern of the boat from sinking under the water, you should not use too heavy devices. Two-stroke models are easy to maintain and lightweight. Four-stroke options are installed on large boats.

Power

A high power engine can capsize the boat during launch. To prevent this from happening, you need to know how much power the device should have. An 8-9 liter motor is installed on a boat up to 7 m in size. With. For a small boat 5 m long, an engine of up to 5 hp will be sufficient.

Making a boat motor with your own hands

You can make a homemade outboard boat motor from a chainsaw with your own hands. It consists of a chainsaw (engine), gearbox and screw mechanism. Step-by-step instruction:

- The propeller is mounted in place of the chain boom, having first removed it.

- The coupling needs to be modified. To do this, grind the cup several sizes smaller and replace the spring.

- Using staples, connect the cup and the coupling cover. The brackets are clamped with a screw and washer.

- The connecting pin between the cup and the shaft is closed with a screw and a bar.

- The shaft and motor are connected by a channel.

- There should be a small gap between the support frame and the front coupling cup.

- A gearbox is mounted on the other side of the shaft.

- A piece of pipe is installed for the rotary motor. It is intended for fastening the guide. The diameter of the rod must match the size of the hexagonal part.

After fastening the screw and shaft, be sure to fill in transmission oil. The lid is mounted on top and secured with sealant.

With gearbox

Assembling a model with a gearbox is difficult, as a high-quality connector is required. For the motor, you can use a four-stroke engine and wide pushrods. The gearbox is installed near the top flange. The wiring is carefully insulated, this will help avoid short circuits. The upper rod and carburetor are sealed with sealant. The motor is equipped with a high-quality water pump.

Making an engine from a screwdriver

Good homemade motors for boats are made using cordless screwdrivers. It is optimal to use a device with a battery voltage of 12V. It will be possible to connect a car battery with a capacity of 45-55 Ah to such an electric motor. Refinement will consist of several stages.

Lifting mechanism

The propeller of an electric motor for a boat made by yourself must move not only in a horizontal plane, but have a certain immersion limit and rise completely out of the water. The simplest design would be a system of clamps to which the engine is mounted. It is rigidly attached to the transom using a steel frame and plate. The clamps are equipped with rings through which the tube will pass. There will be a shaft made of steel wire or rod running inside. To ensure easy sliding, bearings of suitable dimensions are pressed inside the tube.

Gearbox and propeller

The screwdriver is capable of developing high speeds, which is required when drilling. A homemade electric motor for a boat does not need such high speeds, so a gearbox is installed to reduce them. The most suitable option is to attach a gearbox from an angle grinder. In the screwdriver chuck, it is enough to clamp the top part of the shaft to ensure a reliable connection.

The role of a propeller can be played by an impeller from a car pump or a computer cooler. But such a home-made electric motor will not be able to provide the boat with the required speed. You can make a propeller from a piece of stainless steel 2.5-3.0 mm thick.

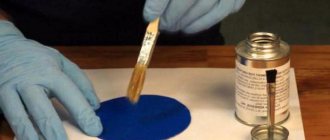

- First you need to cut out a square blank measuring 30x30 cm.

- A square with a side length of 5 cm is marked in the center. Diagonal lines are drawn through the corners. The cut will go through them to a small square.

- Each petal should be rounded and rotated along its axis by 30 degrees.

- A hole is made in the central part for attachment to the gearbox.

- All that remains is to reliably connect everything and test the resulting boat electric motor with your own hands.

Boat mounts

The mounting location for the outboard motor is called the transom. This part must be durable and reliable. In order to correctly design the part, they carefully study the technical characteristics of the boat and the motor, since the transom creates additional load. The transom for an inflatable boat consists of:

The edges of waterproof plywood are treated with sandpaper. Loops for metal staples are installed on the plate. The fastening arcs are bent using a machine; you can do it manually. Eyes are made of plastic or bought in a store.

Homemade boat motor from a trimmer

A gas trimmer is a very successful tool for converting into a boat motor.

.

See for yourself - it has almost everything you need - an internal combustion engine, a rod with a shaft transmitting torsion and an angular gearbox. All that remains is to equip the trimmer with a suspension on the transom, change the throttle control handle and install the water propeller.

The petrol trimmer is equipped with a centrifugal clutch, so the screw will not rotate at low speeds.

Here's a video

testing such a modification.

As you can see, a homemade boat motor from a gas mower does its job perfectly.

Boat motor from a lawn mower

To get a boat motor from a gas mower, you will have to modify the latter a little, spending very little time on it. Compared to an electric motor, gasoline engines are cheaper and easier to repair; moreover, they are more economical and do not require you to carry a battery with you. Since there are conversion kits that include a stainless steel propeller and drive, as well as a set of other components, there should be no problems with installing such a motor on a boat. If you purchase all the necessary parts, then in 20-30 minutes you can easily get a boat motor from a trimmer.

In this case, you get a simple device, but it can be complicated in order to make it more convenient to work with. Unfortunately, this will require not only ingenuity, but also technical conditions. One option is to install a vertical leg.

How to do it:

- You will need a gearbox from an angle grinder to get a right angle.

- The tube from the trimmer will have to be shortened, and bearings will have to be installed instead of bushings.

On a note!The bearings inside the tube are pressed with a regular hammer using blows around the circumference.

- The screw can be made from a strip of duralumin, 10x30 cm in size and 2 cm thick. First you need to make a stencil, which is then applied to the workpiece. Markings are made using the stencil, after which the screw is easily cut out using a sharp chisel. All burrs are removed with a file. Each blade should be bent so that they are 1 cm away from the horizontal line. To do this, you can place the screw on a flat surface and make the desired bend.

On a note!After the screw is manufactured, its shape is finalized during testing.

- A hole is drilled in the center of the screw to secure it to the motor shaft. You can protect the boat's cylinders from emergency situations by protecting the propeller with a ring attachment. After securing the motor to the boat, sea trials can be carried out.

Boat motor from a screwdriver

New videos

about fishing only with us.

As you can see, it is assembled from very simple parts - pins, boards, ties, the only rarely used part is an angular gearbox for changing vertical rotation from a screwdriver

into a horizontal screw.

Watch the video of testing such a boat propulsion unit.

The speed is, of course, less than that of a boat motor from a gas trimmer, but operating an electric motor is several orders of magnitude cheaper.

Firstly, you can connect a small 12 Volt battery from a motorcycle, this will give you an energy reserve for 6-8 hours of engine operation.

Secondly, the cost of electricity is very low compared to gasoline. Let's remember the Tesla electric car - its range of 250 kilometers costs the owner 150 rubles spent on charging the batteries, but how much gasoline does a sports car with the same speed characteristics consume?

Homemade Boat Electric Motor From a Screwdriver

How to construct a homemade electric boat motor

from a drill?

You never cease to be amazed at the engineering minds of ordinary people. And how was it possible to think of assembling a homemade electric boat motor from a drill? That it has been successfully used for a long time, and in different design solutions. And there is a possibility that the trend towards the manufacture of such products will gradually increase.

By assembling a motor from a drill, you will save a decent amount on purchasing a ready-made motor.

Advantages of an electric motor from a drill

There are several reasons for this:

- Not everyone can afford to rent a boat motor;

- environmental legislation strictly regulates the introduction of industrial motors;

- a homemade boat electric motor operates virtually silently, which is important for a fisherman;

- Electric motors cost the user significantly less than internal combustion engines.

Required power

The power of the drill motor is approximately 150 watts.

First you need to make the right choice of drill. And the main parameter is the power of this device. If it is less than 150 watts, then use such a drill for the production of a boat motor

will be ineffective.

In still water, such a motor will somehow move the boat, but on the river it will not be of much use: it will not be able to overcome the current. This remains conditional for our client, since it is necessary to take into account both the size of the boat and the speed of the current.

But practice shows that it is better to make a homemade electric boat motor based on a powerful battery-powered hammer drill. You, the hammer drill is equipped with reverse and has several operating modes. For a boat motor this is of fundamental importance.

Together with it, it will be possible to regulate the speed of the boat when fishing “on the track” (trolling).

Operating voltage

The second point, which is very important, is the operating voltage of the electric motor. It is incorrectly believed that the ideal option is to use 18-volt cordless drills. But for the production of a boat electric motor this is absolutely not to the same extent.

Someday, however, the battery will fail, and he will have to find a replacement. How many of these batteries can you find? Exclusively in specialized power tool stores, and at the highest prices. This approach is impractical.

It is much easier to use a drill that operates on 12 V. Finding a battery for it will not be difficult for you. A regular car battery will do. And of course connect it with wires: they won’t interfere in the boat.

Required tools and materials

What you need, you have a drill in your assortment set, so let’s start making an electric motor for the boat. For this undertaking you will need:

Diagram of a homemade motor for a boat.

- square tube (20x20);

- 4 clamps;

- 3.5 gearbox;

- iron tube (diameter is not just 20);

- rod for shaft production;

- metal sheet for the production of impeller;

- apparatus;

- Bulgarian;

- screws;

- screwdriver

Lifting mechanism for impeller

First, you have to figure out a mechanism that will allow you to raise the impeller above the water.

The most common solution is to weld an iron tube to the clamps, on which a base is required to be hinged, which is the frame of a truncated quadrangular pyramid, with its smallest base directed towards the water.

A bearing frame is fixed to the top of the base (the larger base of the pyramid), and a tube is welded to the bottom of the base. A shaft is passed through the tube and through the bearing.

You will like even a wire with a huge diameter, but its mass will be unusually large, which is no better. It is better to use a tube of the smallest diameter.

The second argument for obtaining a tube is that there is an option to provide it with bearings in the upper and either upper parts of the outer pipe.

There will be less friction and vibration of the shaft in the pipe body will be virtually eliminated.

Gearbox installation and propeller manufacturing

The battery of the drill is expected to be 12 volt.

Gearboxes are required on both ends of the shaft. Craftsmen advise making a gearbox with your own hands for a certain type of electric motor in order to make the number of revolutions good. This will be quite difficult and time consuming. They use a gearbox from used equipment; otherwise, purchase it in a retail chain.

Only one condition must be observed when selecting a gearbox: the transmission number does not need to be made very large. In the correct version, the gearbox should reduce the number of revolutions

drill 5 times. Pessimists say that there is practically no such number of revolutions, and the boat will not develop speed.

We hasten to dissuade you: this will not affect the speed, but the motor will not burn out due to excess load.

Propeller for screwdriver 2. Boat motor from screwdriver

Warm greetings to everyone, in this video I tried to swim with a screwdriver with an impeller from a car, the speed is left to our client.

Boat motor from a screwdriver

New fishing videos only here

The lower part of the pipe can be easily equipped using a gearbox from a used angle grinder. All that remains is to add an impeller to it. You can use a ready-made propeller from other devices, for example, a cooler from the power supply of an old computer. But such an impeller will not create a water flow sufficient to move the boat. It is recommended to make the propeller from sheet metal.

To do this, cut out a square with a side of 30 cm from a sheet of tin (thickness no less than 2 mm) and make 4 slits in it from the center of each side to the intersection of the diagonals. There should be a distance of 5 cm between the slots.

You will get 4 “petals”, the edges of which need to be given a rounded shape. We give them the desired shape and rotate each blade 30 degrees from their axis.

If you are using a gearbox from a grinder, then you need to make a hole in the central part of the propeller, and it can already be secured to the shaft using a locking nut.

Now you need to connect the upper gearbox directly to the drill. It’s good if the gearbox shaft can be clamped in the drill head. Then the work is simplified to the limit: we clamp the shaft and attach the drill itself to the base using clamps.

Sometimes the design of the base does not match the dimensions of the drill, so a tube is used to connect the gearbox and the electric motor. It should fit tightly onto the gearbox shaft. To prevent rotation of the shaft inside the tube, reliable fixation is necessary.

For this purpose, make a through hole through the tube and shaft and secure them with a pin. You can do the same when connecting a pipe to a drill.

The construction of an electric outboard motor from a drill engine.

Homemade boat electric motor

almost ready for action: let's start testing and configuring it. There is no need to put it on the boat and immediately set off across the pond. You can simply lower the impeller into any container of water and turn on the electric motor.

You should feel the flow created with your hands. Check its operation in different modes. If movement is felt, then a homemade boat electric motor

can be used on a pond.

During testing, the motor should operate in normal mode and create a normal background noise.

The considered design of an electric motor for a boat has two very serious disadvantages:

- It is not possible to rotate the electric motor relative to the vertical axis. It will turn out that to control the boat you will need to use an oar, and this is not very convenient for fishing.

- The self-assembled boat electric motor is not yet equipped with convenient controls.

Improvements to turns and controls

Diagram and image of a homemade boat with a drill motor.

Both shortcomings are eliminated during subsequent revision. First we place the base on the swing bridge.

The simple design is as follows: on the fastening, which is secured with clamps, you need to weld a bolt in the central part. Weld a piece of pipe to the base, the diameter of which is comparable to the diameter of the bolt.

The pipe fits onto the bolt, and you will be able to rotate the base along with the electric motor.

A handle is welded to the base, onto which the regulator for supplying current to the electric motor is connected. It can be any rheostat. In this case, the drill will have to be slightly modified by connecting its motor directly to the rheostat. This design will be more functional.

You may have a question: is it possible to simplify a homemade electric boat motor

constructively in order to ultimately reduce its price and time spent on assembly? The answer will be this: it all depends on what components you have available. Craftsmen recommend using a flexible shaft to create electric boat motors.

The convenience of this design is positioned in the fact that you can do without a gearbox. The torque from the engine will be supplied directly to the impeller through the shaft. The problem with this design seems to be that the friction of all elements of the flexible shaft in the protective casing is quite large, and this will create additional load on the electric motor.

The second negative point is the number of revolutions: the motor simply cannot withstand it for a long time. You will need at least one gearbox. You can only do without the upper gearbox.

The shaft is fixed in the drill head, located vertically. The motor will rotate the shaft itself, which will simplify the design.

At the bottom, a gearbox is needed, at a minimum, to change the direction of torque transmission.

How to correctly calculate the loads and what should happen?

You can also make a screw yourself by turning it out of metal.

It should be noted that a well-selected gearbox for a boat motor is perhaps the main condition for its long-term and reliable operation. An accurate calculation of the parameters will not hurt you. This work is not easy, so it makes sense to seek help from an experienced engineer. In addition, consultation with an engineer will allow you not only to select the gearbox specifically for it, but also other components of the design.

Well, if there is no marked specialist nearby, then you have only two options: use the trial and error method or find the necessary information in technical publications. There you will definitely get all the data about the characteristics of any gearbox.

Craftsmen claim that for a boat motor

The gearbox from almost any trimmer is ideal. By the way, using parts from a trimmer for an electric boat motor is a very good idea. See for yourself: gearbox, shaft, protective tube - everything is available.

All that remains is to connect this structure to the engine.

A homemade electric boat motor in any design will cost much less than a factory-made analogue.

But don’t think that a full-fledged replacement has been found. You will lose in other areas: speed, power, power reserve. Factory motors are capable of operating for a long time in various operating modes.

A homemade electric boat motor , the design of which we are considering, is capable of reaching speeds of up to 8 km per hour (in still water); charging a car battery lasts approximately 5 hours (with interruptions).

This electric motor is designed for a lightweight boat with two fishermen on board. In many cases, such a motor will be the best option: smooth and silent running, ease of control and ease of transportation.

Try this motor in action - you will like it!

Source: https://vdiweb.ru/samodelnyj-lodochnyj-jelektromotor-iz-shurupoverta/

Related Posts

Restore Screwdriver Battery Video

A comfortable owner, better than anyone else, understands how comfortable and effective a self-contained hand-held power tool is in use. A professional builder who deals mostly with finishing work is completely unable to do without a screwdriver. However, a battery, no matter what type, loses its energy potential after a certain time. Purchasing a new battery is an expensive pleasure. Who said […]

Replacing Batteries in a Screwdriver Battery

Screwdriver battery repair. Diagnostics and replacement of elements Any equipment breaks down constantly. This also happens often with screwdrivers. No one will want to take up an ordinary screwdriver once they have appreciated the advantages of this type of device. Batteries become unusable. It is harmful to rush to throw away a faulty battery. Repairing screwdriver batteries is not difficult if you follow the instructions […]