Hanging transom design

The basis of the transom design is a board, a stop, an axle with a ring and a retaining bracket (its size and shape vary, depending on the fastening method).

The plate size is 35 by 26 centimeters. The total width of the structure from the axis to the stop is 108 millimeters. With such dimensions, the load distribution is the most optimal (on the upper and lower parts of the cylinder).

Also, in the lower part of the transom, however, on a PVC boat, not a rubber one, wheels can be installed. Transom wheels are designed to make moving the boat more comfortable into the water or onto the shore.

Disadvantages of a suspended transom

The main disadvantage of an outboard transom is the low permissible weight of the engine that can be mounted on it. The rigidity of the structure is achieved due to the force of inflating the cylinders, so if the engine is turned on at full power, there is a high probability that it will be “sucked” under the bottom of the boat. Accordingly, its front part will rise up, which will entail a subsequent capsize.

For this reason, only a low-power electric motor, designed for 1-1.5 hours of active use, no more than 2 hp, can be attached to a rubber boat.

The maximum power of such an engine is not enough to bend the motor under the boat.

When installing the transom, you need to pay attention to the following two points:

- Most often, the cause of “leg stealing” is insufficient pressure inside the cylinders. Under critical load, they are easily compressed, so the motor begins to move freely in the grip. Therefore, the cylinders should not be deflated.

- It is believed that the controllability of the vessel depends on the angle at which the transom is installed. In most cases, it is mounted at 90 degrees, although in the factory configurations of some models the angle of inclination is 76-80 degrees relative to the surface of the water, this is done because on small cylinders the transom bends. At low speeds, the tilt angle does not particularly affect the transom itself, but during the operation of high-performance engines, the second tilt angle option turns out to be more preferable.

Mounting a motor to a boat

Based on the fact that the motor is the main part of your entire boat, we can say that mounting the motor is an extremely important process. When installing it yourself, it is important to follow the important instructions. The best option would be to consult with a specialist on this issue:

- Absolutely all outboard boat motors have special attachment points to the boat - these are the so-called transom brackets. Remember that the outboard engine is always mounted exactly in the center of the transom of your boat. This happens with the help of staples and clamps. The clamps must be very tightly tightened. As you move through the water, it is best to periodically check how well they are tightened. If the motor is not installed well, the boat may be difficult to control;

- If you have a special cable for safety, it needs to be secured to the transom bracket of the outboard motor. The other end should be firmly fastened to the boat. Due to this, you will not lose your motor if your mounts suddenly become weaker. Or, if a boat capsize and other emergencies suddenly occur;

- When installing an outboard motor, you need to find the keel line of the boat - this is its center. When installing a boat engine, it is important to check that your boat has good balance. Otherwise the boat may not be very controllable. If the boat does not have a keel or it has an asymmetrical design, then mandatory consultation with a specialist or manufacturer is required;

- The angle of deviation of the waterline from the axis of the outboard motor propeller should be as minimal as possible. This is done so that the water resistance is also minimal. Additionally, the height of your transom mount will have an impact on water resistance. If the setting was too high, then cavitation may occur. If the motor is too low, water resistance will increase, causing your motor to lose power.

We recommend reading: Description of the Sea Pro outboard motor

YouTube responded with an error: The request cannot be completed because you have exceeded your quota.

Transom Mount

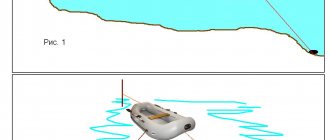

There are several methods to attach a transom to an inflatable rubber or PVC boat.

The simplest one is using a pocket pad that is glued to the base. Its fixation is carried out through rings, and a strong, rigid rope is passed through them.

You can also attach the transom to the protruding rubber parts of the hull. If they are not provided for in the design, they are glued (using the thermal bonding method under the influence of a construction hair dryer). In this case, a metal bracket is passed through the clamps, which is attached to the plywood part with nuts (with washers on the opposite side).

Another fastening solution allows you to install a motor up to 2.5 hp.

This is how you can attach it to a rubber boat:

Electric motors. Part 2

Application of electric motors

Question – “ What are outboard electric motors for?

“It’s not very simple.

Indeed, why are these engines needed if there are outboard motors with internal combustion engines, which are superior to electric motors in many characteristics. But in order to understand this in detail, you first need to take the following information as an axiom - they are DIFFERENT

. Different like an airplane and a helicopter, like a car and a motorcycle, or if we want to stick to our water-motor theme - like a boat and an inflatable boat. All boat engines have the same task - to propel the vessel. But the approach to solving this problem is different between electric boat motors and internal combustion engine boat motors.

If you delve into the history of the issue (and we at Lodki-Peter love this very much), it turns out that the first outboard motor was not a gasoline one, but an electric motor! Indeed, the first electric outboard motor was created in 1880 and demonstrated to a wide international public at the World Exhibition in Paris by the Frenchman Gustov Trouve in 1881, and the well-known Ole Evinrude invented his first outboard motor with an internal combustion engine only in 1907. But, if at the border of the 19th – 20th centuries this was associated with the development and race of technology, today, in our 21st century, technology allows us to successfully create different types of engines. And, as we will see later, electric outboard motors are in no way inferior to their counterparts with internal combustion engines, and in some cases they are even superior.

The main advantages of electric motors: — Quiet operation — Ease of operation — Compact dimensions — Light weight of the engine — Ability to install the same engine on vessels with different transom heights — Reliability — Ability to walk through heavily overgrown reservoirs — Possibility of mounting on the sides or bow of a vessel — For Most boats with an electric motor do not need to obtain a certificate for the right to operate a small boat and register them with the State Inspection Service

These are the main advantages of electric boat motors, each of which should be considered separately.

Indeed, during operation the electric motor makes virtually no noise. The only sounds that the driver and passengers hear in a boat with an installed electric motor are the waves splashing against the bow and sides of the boat. Otherwise, as if by magic, the boat glides through the water quietly and silently. Another useful difference between outboard electric motors and most PLMs with internal combustion engines (with the exception of specially designed motors and motor oars) is their ability to pass through heavily overgrown bodies of water. This useful quality is achieved by the special streamlined shape of the gearbox and the ability of the propeller to cut, rather than wrap around, aquatic vegetation. Another useful property that a boat with an electric motor installed on it acquires is maneuverability. Thus, on modern electric motors it is possible, with one movement of the hand, not only to instantly slow down, but also to engage reverse, which can be very useful when passing difficult sections on some bodies of water.

These properties of electric motors were appreciated by trolling enthusiasts and hunters. And if for fishermen it is important to ensure smooth movement of the boat at low speed, then for hunters it is necessary to be able to quietly approach the hunting site, and often through a heavily overgrown body of water.

The main advantage of boat motors with internal combustion engines compared to electric ones is usually the higher speed of the vessel. Indeed, if you conduct an experiment and install a small gasoline engine with a power of 2 - 3.5 hp on the same boat. and then an electric motor, it turns out that the speed of movement under an internal combustion engine engine will be greater than with an electric motor. But this is precisely a manifestation of the difference inherent in the very concept of the development of these engines. So, if the main indicator of a modern outboard boat motor with an internal combustion engine is power measured in horsepower or kilowatts, then for electric motors everything is a little more complicated. The main indicator is the pulling force, measured in kilograms or, more often, in British pounds. An additional indicator is the weight of the vessel, indicated in kilograms, which can be driven by an outboard electric motor. Thus, the main task of the electric motor is not to ensure high speed, but smooth and constant movement of the vessel.

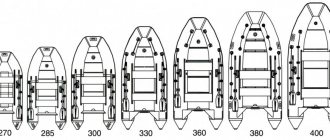

Separately, it is worth considering the issue of installation methods for outboard electric motors. Unlike classic PLMs with internal combustion engines, the installation of electric motors is provided not only at the stern, but also on the side or bow of the vessel. Moreover, for ships with a rigid hull and RIBs, where powerful gasoline engines are used as a propulsion engine, allowing you to quickly get to the desired place, installing electric motors on the bow of the vessel is more preferable. The principle that is used here can be expressed in simple words - “pulling is easier than pushing.” Plus, this installation of an electric motor makes the vessel even more maneuverable. Another interesting feature of modern outboard electric boat motors is the possibility of installing them on vessels with transom lengths of both S and L. This is achieved by the fact that the motor control unit and the gearbox with the electric motor are located on different parts of a sufficiently long metal rod, the depth of which can be immersed regulate. As the Boat-Peter tests have convincingly proven, this feature of electric motors can be successfully used if there is a need to install the engine on a small inflatable boat.

Moreover, installation of electric motors is possible even on rowing models of inflatable boats, and all that is required for this is to contact a service center, where a hinged transom can be installed on any inflatable boat. There is also a separate type of electric motors that are installed on the anti-cavitation plate of the main engine, but these models have not gained mass distribution due to the technical complexity of their installation and inconvenient control.

Based on the type of control, modern outboard electric motors can be divided into three main groups:

— Electric motors with tiller control:

These are the most common engines that are controlled using a tiller. The tiller has several forward speeds, a neutral position where the electric motor is turned off, and several reverse speeds. There are no more additional levers or switches on these engines. The length of the tiller can be easily changed depending on the owner's preference or situation.

— Electric motors with remote control:

The electric motor is controlled via a radio channel using a key fob, which can be attached to the wrist or in any other convenient place.

— Control using a pedal:

Despite the seeming unusualness of this solution, nevertheless, it has proven itself to be exclusively positive for fans of spinning fishing, since it leaves the fisherman’s hands free and allows him to maneuver the vessel without being distracted from catching a trophy.

The reliability of modern outboard electric motors is determined by the fact that they contain a minimum of mechanical parts. Essentially, they have a maintenance-free gearbox with an electric motor at the bottom and a control unit at the top. According to the statistics of calls from owners of electric motors to the service center, the main malfunction is the failure of the electronic board that controls engine speed. As a rule, it burns out due to the engine being completely immersed in water and moisture getting inside the control unit. Repairing this fault takes 15 minutes and consists of replacing the burnt-out board with a new one. They also sometimes ask for replacement of a plastic propeller whose blades are severely damaged by rocks or other underwater obstacles. But the propeller on any outboard motor is a consumable item, and you can easily replace it on an electric motor yourself.

Read the continuation of our research on outboard electric motors in the following publications. Topic: features of use and equipment of modern outboard electric motors.

Pavel Prudnikov “Boats-Peter”

Return to the list

How to make a transom for a rubber boat yourself

The design of the transom is so simple that you can make it yourself, specifically for your boat size.

In order to attach the transom to fairly small rubber cylinders, you will need to make a rigid base on the floor of the boat. Usually plywood is used, the thicker the better. Chipboard is not used, since it is heavy and has a more complex structure for fastening. The floor is cut to the size of your watercraft. It is worth screwing strips of rubber from the car's inner tube to the sharp edges of the plywood with screws to protect the cylinders from chafing. There is no need to make such a floor for the entire boat.

A metal plate with two metal tubes welded to it is screwed to the plywood, into which two equally bent reinforcing pins will be inserted twice at right angles.

The seat serves as additional reinforcement of the structure. To ensure that the motor does not bend under the bottom, but rests on the back of the boat, iron plates are welded to the fittings and two layers of moisture-resistant plywood are screwed to these plates. This is a support for the motor. The transom height is determined by your motor model. Ordinary plywood will have to be painted in several layers and protected from moisture.

Another idea on how to make your own transom for a rubber boat is presented in the video: