Manufacturing nuances

Based on observations, the optimal volume of water located under the inlet of the pipe is a volume that is one to one and a half diameters larger than the inlet conduit.

After a boat with a homemade water cannon overcomes shallow water (with a depth of 0.100-0.150 m), rare tremors may appear. It is at this moment that the motor can become clogged, and therefore it is advisable to install a filter on it.

In the process of assembling a water cannon, it is advisable to use drawings using specialized equipment.

During operation, the jet engine for pvc boats operates in normal transient mode. Therefore, it will be able to reach speeds of up to thirteen to seventeen kilometers per hour. With these indicators, the propulsion unit will easily ensure that the PVC boat is brought to the glider.

The efficiency of water jet motors that are installed on PVC boats is approximately fifty percent. To increase efficiency, when choosing a propeller, you need to focus on the size of the motor.

Conditions for using a water jet engine

Water cannons are considered universal devices, so they are used at any depth. There are no special requirements for units when installed on a PVC boat. The main thing is not to make a mistake in calculating the required power of the engine itself, which corresponds to the parameters of the vessel. It is worth taking into account all the features of controlling the watercraft, which will allow you to gain advantages in maneuverability and speed when operating the engine.

Homemade water cannons are used along with factory models, but are much cheaper both to create and to maintain.

DIY water cannon

Let's look at how to make a water jet for a boat with your own hands. Cunning craftsmen came up with two options for homemade water cannons.

Based on a boat motor

Experience has shown that the most successful homemade water cannons are made from the Veterok-12 outboard motor. But you can use any other one. Usually the old models are used: “Moscow”, “SM-557-9L”, “Strela”, etc. The main advantage of Veterok is the prevalence and accessibility of the necessary parts.

The water duct can be placed both outside the boat and inside it. The second option is used more often, since with an external location the hydrodynamic resistance of the craft increases. Some elements of the water pipeline are made from pipes, others are welded from blanks cut from a stainless steel sheet.

Water cannon on "Veterok"

You can give the workpieces the desired shape using a mandrel (manually) or bending rollers. The impeller blades are cut from the same material. They are then profiled and welded to the hub.

At the design stage, a model of the water conduit can be made from papier-mâché. Then it will be enough to cut it to get a pattern for the development blank.

The transmission of rotation from the engine is carried out through a conventional standard gearbox. It is attached to the main deadwood of the engine using a special flange.

The displacement of this version of the homemade water cannon is 450 kg. Thanks to it, the vessel can reach speeds of up to 20 - 25 km/h and perform planing.

Based on a centrifugal pump

It is suggested to use a Pacer Pumps 200GPM pump with a plastic housing (heat resistant polystyrene) weighing approximately 18 kg.

The pumping mechanism of this device is driven by an Intek engine with a power of 5 hp. manufactured by Briggs & Stratton.

The pump develops a head of 35 m and has 2-inch suction and discharge pipes. Its cost is about $300.

The pump is installed in the boat and then a 2-inch PVC pipe is attached to the pump on the suction side. Through a hole in the bow of the bottom of the boat, it must be brought into the water, equipped with a pipe with a mesh filter - this will be the water intake.

A high-pressure fitting with an outlet hole with a diameter of 24 mm is screwed onto the thread of the discharge pipe. One made of reinforced vinyl is suitable - these are sold today in any store for gardeners and gardeners. The role of the nozzle will also be assigned to a piece of PVC pipe having the same diameter as the fitting. A rubber hose should be used to connect the fitting to the nozzle.

Do not put the nozzle in water. Contrary to popular belief, this technique will not speed up, but will slow down the boat, as it will lead to cavitation.

The amount of jet thrust developed by such a water jet depends on the total length of the suction and discharge lines.

Since hydraulic resistance increases with a decrease in the diameter of the pipe and an increase in the speed of fluid movement in it, it is most advantageous to install the pump as close to the stern as possible so that the length of the nozzle is minimal.

Under such conditions, the pump at maximum engine speed developed a pressure of approximately 20 meters of water column (2 atm), thanks to which the boat picked up speed to 8 km/h.

A tester of such a water cannon may face trouble: the pressure fitting is quite easily unscrewed by a stream of water, and the force of its impact is so great that there is no way to keep the part from rotating manually.

Lubricating the pipe with glue before screwing on the fitting does not give the desired effect - the fitting still breaks off. It is recommended to develop an additional fastening for the threaded fitting or use a pump and fitting with flanges.

VicX › Blog › Water cannon on a cauldron. Part 3. Sea trials

So, I launched it for the first tests. First impressions and indicators lowered all enthusiasm to “0”. I encountered problems: 1. strong heating of the support heel and bearing at the end of the propeller shaft. 2. the speed did not reach 10 km/h. But the brain did not accept complete surrender and began brainstorming))).

Literally an hour later, the issues were resolved by shifting the propeller shaft, and therefore the impeller, to the straightening device. The flaw was in the free movement of the shaft forward to the nose by about 1.5-2 centimeters. Of course, I can’t call it free; I never thought that the shaft would move through 2 bearings. I got out of this situation by installing the washer and 203 bearings in the heel, so that the shaft rests only on the inner race of the bearing. It looks something like this:

Comments 21

Why don't people think about safety, the weak point is the thrust bearing. we went along the river for 100 km. Where nothing is alive. And on this product. along the village only. in hope of the Ministry of Emergency Situations

The whole thing has been sold. And so we mostly go only upstream, you never know what the current will bring home))

yes this is a utopian option

Belt drive is simple.

Water cannons are a theory and hobby of the 60s. And without understanding it, many of our shipowners rushed to replicate and assemble water-jet propulsion systems. In order not to bother your head with numbers, the efficiency is lower than that of a screw. It begins to increase as the speed increases and the size of the vessel decreases. And the best water jets in world shipbuilding are if the engine speed is 6500-7500. This is the theory, the speed of the jet and the volume of water. As you understand then, and even today, it is difficult to find such a domestic internal combustion engine. So they started remaking UAZs and ZMZs at 3200-3500 by tightening the jet. By increasing the speed of the jet, losing volume at a given power and increasing flow resistance and losing efficiency. Yes, the weight of the UAZ and ZMZ engines is simply prohibitive. And there are no words about working at the maximum speed of 3600-4000 of these slow-moving vehicles. An example of a successful water-jet propulsion system is a jet ski, which is where the theory has fully confirmed itself in practice. And in reality, imagine yourself, in the fall, in the rain and snow, you go fishing on a jet ski. cost of fuel, oil maintenance. So fish will be delivered to you by plane from any supermarket. But seriously. Don’t throw away Lifan, but make a motorized paddle. All Asians have been racing in shallow waters and swamps for a long time. Only engines from old cars. The Kazanka is not a successful boat at all, it is the second model after the MKM of the 50s.

))) that’s right, we need to test it on the Chinese!)))

Source

Features and prices

Mercury water gun

When choosing, you need to pay attention to the following technical characteristics:

- type of outboard motor;

- internal combustion engine volume;

- maximum effective power developed by the engine at high speeds (7000 rpm);

- maximum torque at medium speed (4500 rpm);

- stable shaft rotation speed;

- fuel consumption;

- fuel tank capacity;

- type of propulsion;

- propeller screw diameter;

- dimensions;

- weight;

- transom height;

An important point when purchasing a propulsion unit is the price of such a unit; here it should be taken into account that domestic brands that produce water jet systems for boats, as a rule, are assembled from imported components, and at the same time are not inferior in quality to products of foreign brands.

The price range, depending on the components and classes of motors of the Russian brands Kalmar, Medusa, Mikrosha, starts from 38,000 rubles for small boats, and 69,900 rubles for middle-class boats.

Japanese Yamaha outboard water jets start at 540,000 rubles, but they are designed for large boats and boats.

American manufacturers Mercury offer their products from 220,000 rubles.

Jet motor for PVC boat

Assembling a homemade motor for a PVC boat is no more difficult than for other types of boats, but on the contrary, it is somewhat simpler. This is due to the fact that any outboard motors with a power of 15 to 20 horses are suitable for this. In addition, purchasing such outboard motors is not problematic, and their reliability is quite high.

You should also pay attention to the wide range of similar products, which allows you to choose the appropriate option.

At the same time, attention should be paid to models with the lowest weight, which is especially important. In this regard, preference should be given to imported models, although similar outboard motors are also produced by domestic manufacturers. At the same time, it’s no secret that domestic models are not as reliable as foreign ones

In addition, they are characterized by quieter and more economical operation.

At the same time, it’s no secret that domestic models are not as reliable as foreign ones. In addition, they are characterized by quieter and more economical operation.

To build a jet engine for a PVC boat, you should purchase the following components:

- Outboard boat motor.

- Special gearbox.

- Special flange.

- Hub.

- Welding machine.

- Development of the water collector.

- Engine drawing.

- Fittings.

- Waterproof glue.

The technology for converting a regular boat motor into a water jet engine is the same as for making a water jet for a regular boat.

PVC water cannon

Watch this video on YouTube

Preparatory procedures

This is a very important stage in creating a water jet for a PVC boat, since its operational capabilities will depend on correct actions. At the same time, you need to take into account such things as the availability of special tools, as well as the availability of materials that meet the stated technical characteristics.

As a rule, such work is not considered particularly difficult and almost any boat owner can handle it if they wish.

Manufacturing process

As a rule, the inlet part of the pipe should be 1.5 times larger in diameter than the conduit itself. When crossing very shallow areas, 0.1-0.15 meters deep, rare tremors are possible, which indicates an insufficient amount of water entering the water cannon. It is at this moment that it can clog. This is due to the fact that in particularly small areas the pipe can capture silt or sand, along with the presence of other objects. To prevent this from happening, it is necessary to provide an input filter.

In order for the structure to work properly, it is advisable to manufacture it according to the drawings. Finding them will not be difficult, especially if you have the Internet. Although options with unfinished drawings are possible. That is, there are possible drawings according to which the water cannons were not manufactured and their performance was not tested. Such work requires special tools and special skills in working with materials and tools.

The water jet for a PVC boat operates in a normal transition mode, capable of bringing the boat to planing at a speed of 13-17 km/h. The efficiency factor (COP) of such structures is no less than 50%, which is quite acceptable and something that the classic type of outboard motor cannot boast of.

Conditions for using the water cannon

The operation of a water jet is based on the following principle: water is pumped into the working chamber through a water collector due to the operation of blades located on the impeller (impeller). As a result of such work, excessive pressure is formed in the chamber. After which, water under pressure is released from the working chamber, which ensures the movement of the boat. In this case, the principle of jet propulsion used in turbojet engines is used. This occurs due to the difference in the diameters of the inlet and outlet openings, as well as the presence of a turbine: in our case, it is an impeller. The impeller rotates due to a cardan drive coming from the boat engine.

The peculiarity of the design is that a PVC boat can be operated at any depth, including the smallest, which is unacceptable with a conventional outboard motor.

In this case, it is very important to match the motor power directly to the dimensions of the boat and its weight. This means that you need to know the technical characteristics of the watercraft. There may be cases when it will not be possible to install this type of engine due to the technical condition of the boat. At the same time, do not forget that being on the water with faulty elements is very dangerous.

Source

How does a water jet engine work?

In fact, the design is not much different in principle from the principle of operation of an engine with a screw. There is also a screw called an impeller, which, when rotating, creates a stream of water that propels the boat.

The impeller is placed inside the water jet, the inlet and outlet holes of which are not the same. The design is equipped with a control device called reverse steering, with the help of which the water jet is directed in the desired direction, which leads to a change in the direction of movement of the boat.

The internal part of the water jet is made in a profiled version, due to which the turbulence of the water flow is reduced until it enters the impeller operating area.

The control device is capable of directing the flow of water in the desired direction. In addition, you can force the boat to sail in reverse by switching the control device to the “reverse” position. This function is quite useful, as it allows you to get out of difficult situations, especially if there are a lot of thickets.

As a rule, the speed of movement in reverse is much less than when moving forward, since the inlet and outlet of the device have different thicknesses, that is, diameters.

BOAT WITH WATERJET WITH YOUR OWN HANDS, engine from a foreign car, water-jet turbine

Watch this video on YouTube

Advantages and disadvantages

Advantages:

Good protection from mechanical damage and the ability to avoid cavitation. The ability to navigate a vessel through shallow water, overcome clogged areas of reservoirs (littered fairways) and even individual obstacles protruding from the water (rifts, shallows, etc.), where on a conventional screw motor the propeller, or even the motor itself, can be destroyed. Safety - the impeller is located inside and is not dangerous for people nearby in the water. At high speeds, the efficiency is higher than that of propellers (either an increased maximum speed or fuel economy is provided.) Jet boats are more stable and controllable - this is because the water jet, as it were, “sucks” the boat to the water, due to which it steers steadily yourself even in sharp turns at high speed. The vessel can make a turn almost on the spot and even move “lagged”—sideways forward—unlike a vessel with a classic screw propeller. There is no need to use a reverse gearbox; braking is possible from full speed; the vessel's run-out during emergency braking is the shortest. Less hydrodynamic noise compared to screw propellers, which is very important for submarines.

Flaws

- Less efficient than propellers at low speeds (for example, during startup/acceleration) due to: The need to transport, in addition to the payload itself, also water in the pipeline (as a working fluid);

- Power loss due to friction of water against the walls of the pipeline;

- Power loss due to turbulent turbulence of the water flow in the water jet channels.

]

How to create an engine yourself?

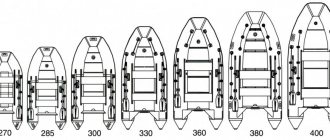

Creating an engine with your own hands is not as difficult as it might seem at first glance. Jet propulsors are usually made by fishermen based on the classic type engine design. The future product may be based, for example, on Chinese or domestic engine models (from 5L to 100L). Drawings of these structures are presented in the following form:

To make a water jet motor, you can use a classic standard gearbox: it must be attached to the main deadwood in the engine area. This is achieved by using a flange. After this, a metal blank is taken, where the design of the water intake, 6 blades and the water intake should be assigned.

To create a workpiece based on a standard design, a file and rollers are used. Afterwards, using the same tools, the product is processed. As a result of the work done, the workpiece receives the required shape. After this, the moment comes to weld the seams of the longitudinal and transverse types.

The water-jet structure must also acquire a hub: an area is allocated for this part in the location of the boss. The boat pump in its dry structure weighs twenty kilograms. However, the pattern of this product may occur in very rare cases. However, anyone can make a pump on their own, since there is quite a sufficient amount of instructional materials on the global network

It is also important to take into account that jet boats have a greater degree of profitability than boats with a simple engine

Jet outboard motors for inflatable boats are much easier to manufacture than for large boats with a jet engine. The main advantage is that almost any type of motor can be used for this type of boat, regardless of design. It is recommended for them to choose water-jet propulsors, the power of which ranges from fifteen to twenty hp.

The most suitable motor option for a boat is considered to be an outboard motor. Compared to a stationary motor, an outboard jet boat motor does not cover the useful volume of the boat and is easily dismantled. The device is characterized by low weight, high level of UM, simple design, and ease of use.

Positive and negative features

Water-jet propulsors are characterized by the following advantages:

- a good degree of protection from mechanical damage, as well as the ability to prevent cavitation;

- the vessel can pass through shallow water, overcome ponds that have become clogged, as well as other types of obstacles that protrude from the water. Water-jet propulsors here turn out to be more optimal than simple screw-type motors, in which the propeller or main motor may suffer;

- safety guarantee - the impeller is located in the inner part of the product and does not pose a danger to those people who are near the boat;

- water-jet outboard motors provide boats with greater stability and excellent controllability;

- water jet propulsion allows the boat or boat to turn right on the spot, as well as move forward on its side;

- the need to use reverse disappears, there is the possibility of sharp braking;

- lower hydrodynamic noise than that of screw propulsors.

- efficiency at low speeds is less than that of screw systems;

- the difficult process of transferring the water mass through the bottom of the water transport to the pump itself;

- the water intake functions like a pump, drawing in small debris from the bottom. Because of this, the cooling system may become clogged or the water pipe, as well as the impeller, may be damaged;

- high probability of rotor wear, because the vessel is operated in shallow water areas;

- expensive repairs;

- A jet boat can act up when moving slowly.

Choosing a water jet

When selecting a product of this type for a boat or boat, you must have information regarding 3 basic components of a watercraft:

In relation to the propulsion, these are traction characteristics, which depend on the degree of power of the engine itself, as well as on how fast the ship is moving.

Homemade boat motor from a drill

In most houses and apartments you can find an old drill or screwdriver. Even in their new form, they are more affordable than an industrial motor. If they run on batteries and have a button to control the speed, then the principle of operation with an electric motor is similar.

- Availability of battery as a power source.

- A propeller with a gearbox sets the craft in motion.

- The engine controls are a reverse button and a rotation speed control knob.

Most factory-made boat products are sealed, and therefore can be used in water. This fact is excluded when choosing a drill or screwdriver as a homemade boat motor, because they are not sealed.

But it is worth remembering that moisture penetration into the controls of an electric drill is fraught with trouble. The engine will stall and the ship will stop. The advantage is that it is very easy to find spare parts for the drill.

Another significant point is that it is not intended to operate continuously. This is not very suitable for boat engines. Therefore, it is advisable to create a power reserve to avoid overheating of the homemade product.

We recommend reading: Characteristics of Yamaha outboard motors

- You need to start from one hundred and fifty watts and more.

- In this case, it is realistic to choose a propeller with a diameter of one hundred and thirty millimeters.

- The total weight of the vessel is no more than three hundred kilograms.

The voltage of drills and screwdrivers can be different, as well as their batteries. But the capacity of the latter is not enough to control the boat. Then a car battery that produces twelve volts will do. It is better to choose a drill with the same voltage.

Of course, a battery of batteries for any voltage will save the situation. But the cost of such a device can be expensive.

Required components

To make homemade motors for boats from a drill, you need to assemble a set of accessories and tools:

| № | Helpful information |

| 1 | slats for mounting the engine |

| 2 | when hanging on the transom, a mechanical part from an angle grinder will do |

| 3 | a pipe with a diameter of twenty millimeters is suitable for making a rod, and a frame made of a twenty by twenty millimeter profile is suitable for installing a motor |

| 4 | metal rod to create the shaft and sheet metal for the screw |

| 5 | hand scissors for tin |

| 6 | electric drill with drill bits |

| 7 | angle grinder with cutting and sharpening discs |

| 8 | self-tapping screws if there is wood in the device |

If you need to quickly remove the propeller, it is advisable to make a lifting mechanism to control the motor in a vertical and horizontal position.

To create the mechanism, you need to equip the clamps with rings and pass a tube through them. This articulated device ensures the reliability of the steering wheel.

Gearbox and propeller

The rotation speed of the drill is slightly higher than that required to operate the propeller. The gearbox will adjust the difference.

- The upper gearbox is capable of reducing speed from one and a half thousand to three hundred. In this situation, a homemade motor will allow the boat to move smoothly.

- The lower gearbox is important for horizontal positioning of the propeller. If it is taken from an angle grinder, just clamp it in the screwdriver chuck.

To make a propeller, you need to select certain sections on a steel sheet. A square of two hundred by two hundred millimeters and a thickness of three is enough. Stainless steel is much more difficult to cut, but it is preferable and lasts longer. You can also use a blade from a household exhaust fan.

You need to make holes in the center of the sheet. They are necessary for the landing screw. The slits are made diagonally, leaving a circle of thirty millimeters in the center.

The blades should be round and equal. Each one must be rotated at a certain angle and direction of rotation so that there is no vibration of the screw.

A test swim is done in any container of water that will fit the propeller. You can go to a small pond and lower the propeller into the water without a boat. Such a test will show whether the completed motor is ready for swimming.

A properly assembled electric motor will return a stream of water, but without vibration. If something goes wrong, a design made for a boat with your own hands can always be improved with the help of a larger angle of inclination of the blades.

We recommend reading: Features of operating 12 volt traction batteries for outboard motors

Before you make a motor for a boat, you need to understand how it will move with its help. It is important to take into account the weight of the vessel with all things, engine power, current strength and operating voltage. The motor power for a rubber or PVC boat must be at least twenty percent greater than the load power. This advantage will be useful in case of force majeure.

It is advisable to measure the voltage under load and during idling using a special device.

Assembly steps

The general principle of assembling water jet attachments for outboard motors is practically no different from different manufacturers. For example, let’s look at the procedure for installing it yourself on a Yama 40.

First you need to separate the nodes associated with the lead screw:

- The gearbox is removed; to do this, you need to unscrew the four bolts and the reverse link nut.

- Remove the reverse linkage.

- Separate the gearbox.

Next, you need to remove the product from the packaging box, inspect for damage and check for completeness:

- Place the impeller shaft into the volute body and secure it with four bolts.

- We separate the pump body from the gearbox, then remove the impeller, plates and rubber seal of the cut-off valve.

- We install the pump on the guide plates and secure it with a key. We put the impeller on the shaft.

- The rubber band from the gearbox must be inserted into the cut-off plate from the kit.

- Secure the cutter with two bolts to the plate.

- Insert the guides from the kit into the volute body.

- Remove the oil seal from the pump and secure it to the body with four bolts.

- Place the oil seal from the kit onto the shaft and place it in the pump.

- Install the bronze adapter onto the pump.

- Screw the plate from the kit to the deadwood with four bolts.

- Place and tighten the locknut onto the rod clamp.

- We put the volute on the motor along the shaft splines and fix it with one bolt. Then we secure it with two long and two short bolts inside.

- Install a new key on the impeller shaft and put on the impeller.

- We install adjusting washers and a plastic and tin gasket.

- A locking plate is placed on the shaft and a nut is tightened, after which it is locked with the plate.

- We install the water inlet and secure it with nuts.

- Connect the reverse rod from the water cannon to the standard switch. This completes the assembly and assembly.

You can choose the right water jet nozzles for Yamaha 15, 30, 40 here: https://motormaran.ru/benzinovye-motory/vodometnie-nasadki/yamaha-1/. Select by parameters for Suzuki, see here: https://motormaran.ru/benzinovye-motory/vodometnie-nasadki/vodometnye-nasadki-suzuki/. If you need to choose water jet attachments for Tohatsu, here: https://motormaran.ru/benzinovye-motory/vodometnie-nasadki/vodomet-tohatsu/.

To select a mechanism, you need to consider:

- Year of manufacture, model and brand of manufacturer.

- Engine power is usually indicated in the digital index of the model name. For example: Suzuki DT15as here 15 will mean the amount of horsepower.

- Technical characteristics of the boat.

Important: Correct selection of the device for the parameters of the boat will help avoid the need to increase the height of the transom. A properly installed unit should be in water only to the depth of the receiver

Where can I buy?

It is better to purchase from official dealerships, or order delivery from them via the Internet. When purchasing the main unit, you should immediately order special lubricants for maintenance.

Cost table in Russia:

| Manufacturer | Motor power (hp) or engine model | Price range (RUB) | Where can I buy |

| SUZUKI (suzuki). | Up to 20 hp DT9.9-15 | 70–90 thousand | https://www.eastmarine.ru/vcd-11999-9-104400/goodsinfo.html |

| YAMAXA (Yamaha). | Up to 20 hp | 40–78 thousand | https://www.eastmarine.ru/vcd-3234/catalog.html |

| 30 hp | 80–95 thousand | https://www.eastmarine.ru/vcd-3234/catalog.html | |

| 40 hp | 85–100 thousand | https://www.eastmarine.ru/vcd-3234/catalog.html | |

| TOHATSU (tohatsu). | 25-30 hp | 120–140 thousand | https://mercury-mag.ru/vodometnaja-nasadka-dlja-motora-tohatsu-25-40.html |

Advice: When purchasing products from a poorly known manufacturer or an unverified supplier, you should pay attention to the quality of the metal used, the tightness of the parts and the reliability of the connections. Be sure to read the certificate and check the possibility of warranty service

And also inquire about the possibility of additional purchases, consumables and spare parts.

Having considered the features of the device, the positive and negative aspects, and its applications, boat owners are thinking about re-equipping their engines. Considering the high cost, the feasibility of this operation should be clearly understood. To do this, it is necessary to analyze the features of the basic operating conditions of the vessel. This will make it possible to make the right choice and understand the need to use these devices for a specific case.

Design and principle of operation

The main components of a water jet are the propeller part and the engine (internal combustion). The water pipeline combines the following elements:

- water intake part - the front area that facilitates the movement of water to the screw part;

- a straightening hardware element that transforms the rotational movements of water flows into rectilinear ones;

- nozzle element;

- the tip of the tube through which water masses find their way out;

- a reversible steering device that allows you to change the direction of movement of the boat (both forward and reverse are provided).

Impellers (screw elements) can be of different types:

Make it a rule, on every fishing trip, the first thing you do is...

- The axial type is the simplest to manufacture, but the efficiency is low. In addition, the presence of the cavitation effect makes it possible to operate only at low speeds.

- Axial-diagonal type - designed for motors with an average number of revolutions. The efficiency level is slightly higher than that of axial impellers.

- Diagonal and auger are modern types of screws that are made using modern technologies. The main advantage of both types is a high level of efficiency and the ability to work with motors with high speeds.

The boat starts to move after jet thrust, which is created due to the ejection of water flow at high speed. A more detailed operating principle is as follows:

- Water flows penetrate the water intake, which is located in the front part of the craft. The water intake includes a mesh that can filter algae and floating debris. When designing a water intake, experts try to provide laminar flow to the water flow, which will significantly improve the overall performance of the motor.

- The impeller throws the water back, after which it enters the narrowed part, which further increases the speed of passage.

- The blades of the straightening apparatus are equipped with a peculiar shape that helps to provide slight resistance to the fluid that moves towards it. Straightening devices can be of various designs. The most popular of them is the scapular compression. It is this type of design that allows the straightening apparatus to simultaneously perform the functions of a nozzle device.

- Water flows enter the nozzle part (if the straightening device does not perform this function). The presence of a small flow area allows the flow pressure to be converted into velocity.

Motor attachments

Attachments for water jets are devices that allow you to convert an ordinary motor (outboard) into a water cannon in a few hours. The nozzles resemble centrifugal pumps, which, using impellers (impellers) through the water intake, draw water flows into the propulsion part and push them out with pressure in the direction opposite to the boat.

The main advantages of nozzles for water jets are:

- The ability to connect reverse at full speed, which gives a fairly powerful braking effect.

- The device is not equipped with switches in the gear section, which does not lead to rapid wear of the motor.

- Easy maintenance.

It is very important to syringe every 9-10 hours with a specialized lubricant (waterproof). The disadvantages of motor attachments include:

The disadvantages of motor attachments include:

Reduction in power indicators by almost a third. High cost of parts, which is especially important during periods of repair work.

A water-jet propulsion unit (also known as a water jet) is an engine that operates using force, which is generated as a result of the release of powerful water jets. A water cannon is an excellent alternative to screw boat motors, especially when it comes to overcoming obstacles protruding from the water and shallow water. This article will tell you how to create a water-jet propulsion system yourself.

The water cannon includes:

- Water-jet tube;

- A screw with an impeller (that is, a shaft);

- Steering device;

- Straightening apparatus.

DIY boat motor from a trimmer

An excellent homemade boat motor can be made from a trimmer. Such an electric motor is made simply because of the similarity of the devices.

There is no need to take away anything from a trimmer or a walk-behind mower or greatly alter it. In particular, the top gearbox remains the same, as does the engine power supply and control system.

The option is considered very profitable and convenient, because the device contains a transmission and an engine. All that remains is to make a mount for the watercraft, remove the area with the disk and install the propeller. But let's not forget about the shortcomings.

- It is worth remembering that the motor for a boat from a trimmer has low power. It is difficult for such a device to swim against the current.

- A trimmer boat motor is ideal for moving on small bodies of water with standing water. And this is not always the ultimate dream of active recreation lovers.

- You will have to get used to the strong noise effect and smoke.

In general, such a homemade outboard motor is not a very cheap option due to the cost of the motor mower. But if it already exists and defects have appeared in it, it can easily be converted into an engine for a wide variety of models of floating craft. It is suitable for small boats; a plywood boat can withstand it due to its lightweight design, and an inflatable one too.

Application

Water cannons are used by fishermen and lovers of river walks in areas with medium and shallow depths and a large amount of grass, snags, and stones. Thanks to the use of a closed screw in the design and a water intake hole protected by a grill, it is protected from jamming when large branches, stones and grass get inside. Small grass and algae that get inside the propeller along with the flow of water through the water intake grille are crushed by the impeller and do not affect the operation of the motor.

Water cannons are well suited for moving along riffles and shallows

Important. The speed and safety of movement of a boat with a jet engine is affected by its installation

When positioned correctly, the plane of the water intake grille should be slightly above the level of the bottom of the boat. In this case, the unit will be protected from impacts on the bottom, stones and snags. When taking water, air will not enter it, which causes failures and a decrease in engine power.

Features of making a jet motor for a boat with your own hands

If you want to make a high-quality water jet engine, then the Veterok brand motor may be the best base motor. There is nothing special about this, since this particular motor is equipped with all the necessary spare elements that may be needed during the engine manufacturing process. You can purchase it in almost every fishing store or on the Internet.

After the purchased base motor is upgraded, the weight of the jet engine will be increased by literally 1 kg, which is not significant for boats of any type. If the motor is manufactured correctly, it will subsequently be able to accelerate the boat to 25-30 km/h with a boat load capacity of 450 kg. In order to create a jet engine from a base motor, you need to purchase the following additional elements:

- motor of a special type Veterok, which is equipped with a flange;

- water collector and its development;

- rectifier gearbox;

- welding machine;

- hub;

- waterproof glue;

- fittings;

- engine drawings and diagrams.

An important nuance before making a homemade motor is that you need to approach the preparation process as responsibly as possible. With an irresponsible approach, the motor can fail very quickly.

When choosing all the components, it is important to choose only reliable ones so that the motor works properly.

To ensure maneuverability on the surface of the water and the so-called maneuverability of the boat in the future, a special recess must be made in the water collector. It also allows you to reduce hydrodynamic resistance. This can only be done due to the fact that the leading edge, located in the upper part, is located 35 mm higher than the level of the boat bottom.

To assemble the motor yourself, you need to have a very ordinary gearbox. It must be secured to the engine using a flange. After this action, you should take a metal blank in your hands, on which you need to draw a scan of the water collector, the so-called shell and blades in the amount of 6 pieces.

Using hybrid rollers and a file, it is necessary to produce workpieces that will have the most correct shape. To do this, you can use a mandrel or do this process manually. In order to connect the transverse and longitudinal seams of the water jet chamber and drainage system, welding work begins. Do not forget that the design of the water cannon must also have a hub located on the very boss of the finished product.

Once the water cannon is completely ready, its weight should be about 20 kg. Drawings of water cannons of this type are very rare on sale. Therefore, you should create it yourself or find it on the Internet.

How to make an engine with your own hands

Most consumers consider water jet engines to be a luxury, because their cost can be one and a half times higher than the price of a motor with a propeller. Therefore, the decision to make water cannons for boats with your own hands will be profitable. Practice has shown that it is better to give preference to manufacturing a water cannon based on the Veterok-12 outboard motor, which will have excellent performance properties. In addition, the cost and availability of serial parts of the unit plays an important role.

After modification, a homemade water cannon for a boat will add only 1 kg in weight, will have a displacement of 450 kg and will allow it to reach speeds of up to 25 km/h.

Schemes and drawings

The main problem may be finding a water cannon of the optimal design. A clear diagram for assembling a device based on Veterok-12 is practically not found on the network.

Drawing of a water cannon for a boat:

Materials and tools

To get started, you need to prepare the necessary materials and tools and make sure their quality. An error during operation or the use of low-grade materials will lead to motor failure. You will need the following items:

- “Veterok-12” or another motor with a flange of your choice;

- special gearbox;

- drainage pan;

- metal for blanks;

- fittings and hub.

Among the tools you cannot do without a welding machine and consumables, a file and bending rollers or a mandrel. You also need to buy reliable waterproof glue from a trusted manufacturer in advance.

Manufacturing process

To achieve the required hydrodynamic resistance and increase the maneuverability of the boat, a special recess must be provided in the water collector. The upper leading edge of the structure should be located 3.5 cm below the bottom. The gearbox is mounted on the engine via a flange. Blade blanks (6 pieces) are drawn on the metal, which will allow you to make your own impeller for the water jet, shell and water collector. You can give the desired shape to parts of the structure using a file and bending rollers or a mandrel.

Afterwards, a large amount of welding work remains to be done: the drainage system and the water jet chamber will be obtained after welding the transverse and longitudinal seams. The hub should be placed on the boss of the device. The location of the water conduit depends on the design of the boat: it can be located in the hull or outside it.

A water jet for a PVC boat is created according to a similar principle. The task is simplified by the fact that any light-weight outboard motor is suitable for modernization - imported models have an advantage in this aspect.