Beginning underwater fishing enthusiasts need to know how to make a homemade gun. This can be done even without special skills, professional tools and precision equipment. There are several key types of underwater guns, differing primarily in the method of throwing the striking projectile - the harpoon. The element that imparts acceleration to the striking projectile and imparts the energy necessary to overcome the resistance of water can be a spring, a special rubber band, vacuum and pneumatics. In addition, hydropneumatic, powder, gas guns and even double-barreled shotguns are produced industrially and made by numerous home-made craftsmen. But since to manufacture most varieties it is necessary to have experience in such work, a variety of materials and drawings to maintain exact dimensions, you should know how to make the simplest homemade underwater gun - an improved version of the so-called Hawaiian.

Beginning underwater fishing enthusiasts will be interested in a way to make a homemade gun without special skills, professional tools or precision equipment.

The Hawaiians, which appeared, as the name suggests, on the islands of Oceania, had an extremely simple structure. Initially, they consisted of a pole with a harpoon tip and a rubber band with a diameter of 10-15 mm, rolled into a circle. Having hooked the rubber band onto the thumb, the hunter used the back end of the pole to pull the rope back to the elbow, after which he grabbed the pole closer to the middle with his hand. After that, all that remained was to aim and unclench your hand so that the compressed rubber band would forcefully push the harpoon towards the target. However, the described method of catching fish is not very convenient for hunting, since holding the harpoon in the “cocked” state requires constant tension of the hand. This drawback can be easily corrected without complicating the design fundamentally, but simply by equipping the Hawaiian with a home-made trigger mechanism. Now let’s talk about exactly how to make a gun for hunting underwater - it’s extremely easy to make, effective and at the same time easy to use.

Preparing for work

In addition to sporting interest, making such a homemade product also makes economic sense, since a specialized hunting store will be happy to offer you the simplest harpoon gun for the price of a crossbow. In addition, a tool made to your taste will allow you to enjoy both processes - manufacturing and the hunt itself. Before you make your own underwater gun, you will need to stock up on the following:

- aluminum tube with an outer diameter of 10-15 mm and a length of 150 cm;

- PVC pipe 25-30 cm long, the inner diameter of which is slightly larger than the outer diameter of the aluminum tube;

- a rectangular steel skewer;

- M4 bolt 20-25 mm long with a nut, metal and rubber washers;

- M4 bolt 40-50 mm long;

- steel rectangle measuring 40×15×2 mm;

- three self-tapping screws 70-100 mm long;

- fishing rubber;

- ring-shaped elastic band;

- nylon thread;

- cutting boards with a thickness of at least 20 mm;

- epoxy glue.

Also, to make a gun for hunting aquatic life with your own hands, you will need the following tools: a screwdriver, pliers, a hammer, a chisel, a vice, wrenches, a rasp, a drill, hacksaws for wood and metal.

In addition to sporting interest, making such a homemade product also makes economic sense, since a specialized hunting store will be happy to offer you the simplest harpoon gun for the price of a crossbow

Separate a 20 cm long fragment from the skewer, clamp it in a vice so that 10-12 mm protrudes from the jaws, and bend the protruding section at a right angle. Having taken the resulting L-shaped part out of the vice, bend it in the direction opposite to the short part of the letter “L” so that you get an arc - a sector of an imaginary circle with a diameter of 50 cm. Drill a 4 mm hole in the middle of the part. In the center of the short tube, drill 2 opposite holes - with diameters of 5 and 4 mm and 2 - with a diameter of 5 mm, 1 cm from the edge. Also, in a short tube at a distance equal to the length between the hole and the bend of the L-shaped part, make a transverse slot measuring 8x2.5 mm. A centimeter from the edge of the aluminum tube, drill 2 opposite holes of 8 mm each, and then make a transverse slot measuring 8x2.5 mm in the center of the tube. From fishing rubber, make a tourniquet 1 cm thick, 40-45 cm long, and every 5 cm, tightly rewind it with nylon thread. From the board, cut a round plug corresponding to the inner diameter of the long pipe and drill a 4 mm longitudinal hole in it.

DIY spearfishing gun

Spearfishing has recently become a very popular activity. This sport attracts more and more people who are ready to test themselves in an unusual environment. But desire alone is not enough; to hunt underwater you will need special equipment, many different accessories and, of course, weapons. All this costs a lot of money, and if at first you can do without a wetsuit, trying your hand at shallow water, then you definitely won’t be able to catch a large fish with your bare hands. In general, hunting without a gun is like playing football without a ball.

Today, specialized stores offer hunters four types of underwater weapons. These are crossbows, pneumatic guns, hydropneumatic guns, as well as spring-type guns. The price of finished products is quite high; not everyone can afford such a “toy”. But don’t give up because of this the dream of catching carp or catfish by meeting the enemy, what is called face to face. In no case!

If you can’t raise money, then the only way out of the situation is to make an underwater gun yourself. You will have to work hard: carefully study the drawings, choose the best option, find or buy all the necessary materials, and perhaps even remember labor lessons from school. But it's worth it. The result of your efforts will be an excellent homemade gun, with characteristics almost equal to the factory one.

Assembling the gun

Now you need to assemble a gun from the kit prepared in this way. To do this, screw the L-shaped part with a short M4 bolt to the PVC pipe, inserting a rubber washer between them so that the short part of the L-shaped part fits into the cut in the pipe wall. The bolt head should not protrude above the inner surface of the tube wall, otherwise it will interfere with shooting. Additionally, secure the L-shaped part in the cut area with a ring-shaped rubber band.

Externally, this springy structure vaguely resembles a bicycle hand brake lever and serves as both a trigger and a sear - a part used to cock the weapon.

First, you need to insert a cut wooden plug, after lubricating it with epoxy glue, into the end hole of the aluminum tube. Then weld 3 self-tapping screws on one side and an M4 bolt on the other to the metal plate so that you get something like Neptune’s trident, where the M4 bolt is the shaft of the trident. Lubricate the M4 bolt with epoxy glue. The resulting trident should be screwed into the hole of the wooden plug. The homemade harpoon is ready.

The aluminum tube must be inserted into the PVC tube, and a rubber band must be passed through the 8 mm diameter holes drilled in the aluminum tube. The free ends of the harness are inserted into holes with a diameter of 5 mm drilled in the PVC pipe and carefully fixed there with nylon thread. This is how, without any special qualifications, in a maximum of 1 hour you can make with your own hands an excellent attribute of outdoor activities - an underwater gun.

Trial

To tension the rubber and prepare the gun for firing, it is necessary to move the PVC tube, which acts as a cocking handle, forward to the tip of the harpoon until a characteristic click is heard, indicating that the metal part that has fallen into the slots of both tubes has fixed the gun in the cocked state. Now pressing on the protruding arc of the metal part will disengage it from the harpoon and a shot will occur. Tests carried out in water show that from a distance of about 1 m, the harpoon confidently pierces the wall of a plastic bottle filled with water , and it is quite difficult to remove it back due to the threads on the self-tapping screws.

Spearfishing with a harpoon

Let's move on to the process of underwater fishing using a self-firing harpoon.

Everything is extremely simple: swim up to the victim, with a sharp movement, place it on the tip of your instrument. If you are a fan of fast underwater fishing and speed is an important factor for you, then you will need to “supplement” your harpoon. To do this, you need a ring made of elastic rubber, which is attached to the harpoon handle on the blunt side.

The recommended rubber for this operation is the rubber used for launching gliders. This type of cord is inexpensive (no more than 200 rubles) and very functional: thanks to it, you can pull a glider that weighs more than 5 kg into the sky, while the skein will be 10 meters. Imagine what two rings made of such rubber can do!!! This is a pulling force of more than 20 kg! Not every spear gun can handle this kind of tension. You can purchase such a cord here.

Of course, the properties of a harpoon are not unlimited: the strike distance of such a weapon, even with a rubber cord, which is coiled in a ring, will be from 80 cm to 1.5 m.

But let’s not forget that a purchased underwater gun operates at a distance of 2 meters. Do not doubt that for almost all inhabitants of the underwater world, a meeting with a hunter equipped with a harpoon will be fatal.

How to make a speargun with your own hands step by step instructions

Manufacturing begins with the spring, which is the most complex. It is made on a special lathe, then subjected to heat treatment and finally covered with an anti-corrosion coating. The length of the spring is measured based on the size of the barrel. It should be 20-30 cm longer than the length of the barrel, since after the first use of the gun the spring will decrease by 5-10 cm.

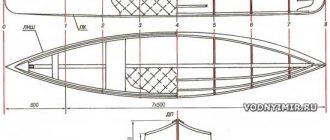

Next, we take on the manufacture of a barrel for an underwater gun. You can use a duralumin ski pole for it. We make the length based on the body of water where they will shoot. It is approximately 60-75 cm.

On both sides of the barrel, cut a thread, cut a slit 15-17 cm long for the sear. It is this length that regulates the force of the gun and its firing when moving the handle along the barrel. Then we make a hole in the trunk to get rid of water.

We grind the muzzle together with the plug from duralumin. In the last one we make a hole into which we insert the harpoon. The barrel is ready, after which they begin to make the trigger mechanism and handle.

The handle is made from two separate plates. They are drilled to the original diameter of the finished trunk, and then the contours are cut out. Next, a slit up to 4 mm deep is made with a file in each plate for the trigger mechanism.

The next operation is to make holes for the sear axis, spring and fuse. The halves in the handle are connected to the barrel and pressed with screws. A ring is placed on the front of the handle to prevent slipping along the barrel. The mechanic makes the trigger, the sear, the spring and the fuse, in a word, the trigger mechanism. He tempers the sear. This completes the assembly of the speargun handle.

The penultimate thing they do is a harpoon (see drawings of a harpoon for a speargun). The diameter in our case is 6 mm. For this purpose, previously purchased stainless steel was used. There is a sliding sleeve along the harpoon, and a line is attached to it. The bushing is made in such a way that it is cushioned by a fluoroplastic ring and rests against a special shank. The latter is designed to secure the harpoon. The tip is made simple - a flag with a wire to hold the fish. They sharpen it for several edges. The trick is that the sharp edges quickly cut through fish scales.

And lastly, they make an easy release. It is cut from solid steel. The cut plate is attached to the plug on the barrel using two screws. When winding, the line is placed under the plate, and in the very center of the barrel it is attached to the fly. When fired, the line easily comes out of the plate and unwinds.

The do-it-yourself underwater gun is ready, it needs to be tested in practice. Insert a harpoon into the barrel and compress the spring until it is fixed to the sear. This is facilitated by a clicking sound, which indicates that the speargun is ready and loaded. They press the trigger and shooting begins. This gun is loaded only in water and unloaded too.

The underwater gun has sufficient destructive power, weighs about 3 kilograms and hits the target at a distance of up to 3 meters. When it is infected, it is quite noisy, just like when shooting. This is a drawback, but it is the only one. To reduce noise, the spring and the barrel are rubbed with glycerin.

www.umeltsi.ru

Manufacturing of main parts

To make a high-quality homemade speargun with your own hands, let’s consider each stage separately:

Trunk. Any metal tube 60-70 cm long is suitable for this element of the gun. The easiest way is to make it from an old duralumin ski pole by cutting off the handle and support rod. First, a thread must be cut at both ends of the resulting tube, then a groove measuring 15-16 cm in size must be cut into it, with the help of which the impact force of the spring will be adjusted. You will also need several additional holes to make it easier to float to the surface. At the last stage, the barrel is equipped with a plug and a muzzle.- Spring. This important part is quite difficult to make at home, so it is better to entrust such work to a qualified turner. It is made from metal wire by winding it around a rod. After this, the product is hardened and coated with an anti-corrosion compound to protect it from rust. The size of the spring is selected according to the length of the gun barrel and taking into account future shrinkage. Ideally, it should be 25 cm longer. After the first shots, this difference will be reduced to 10-12 cm, that is, the spring will become 20-25% smaller. This is the same shrinkage.

Handle and trigger. The material for the handle is two identical metal plates, which need to be clamped in a vice and different holes drilled in them: one for the diameter of the barrel, the other for the trigger mechanism. The sear, fuse and spring are inserted into the latter, after which both plates are clamped with screws. It is recommended to pre-harden the sear.- Harpoon. The result of a shot under water largely depends on this element, so you should not make it from an ordinary iron rod. It is advisable to look for a workpiece 6 mm thick made of stainless steel. A sliding sleeve is fixed on it, to which the line is attached. This part is assigned the function of a shock absorber. You will also need a shank to secure the harpoon itself. If desired, you can equip it with a thread that allows you to change the tips as they wear out and depending on the object of hunting. At the same time, you need to understand that the threaded connection is more susceptible to deformation, and any flaw on the harpoon negatively affects the accuracy of the shot.

Sling

You can’t call a sling or a Hawaiian gun a gun, and from the outside it doesn’t look like one. However, this device itself became the ancestor of all underwater guns.

A sling is a metal tube with a movable tip attached to it. The other end has a spring or rubber band. To activate the device, a spring or rubber band is pulled to the middle of the tube. At this point, the hunter, holding it with his hand, releases the tube after aiming. The tension force will throw it sharply at the target. You can make such an underwater gun with your own hands without any problems, even at home.

Spring shotgun

It is more widespread than all previous ones. It was especially popular until the middle of the last century, although some people still use it now. The gun has a powerful spring, under the influence of which the harpoon is thrown out of the barrel.

There are several modifications of this gun, with differences in the spring mechanisms, which:

- Springs stretch;

- The springs are compressed;

- Two springs - the first is compressed, and the second is stretched.

In addition, one gun can be equipped with two springs of similar action, but different in diameter. A thin spring is placed inside a thick one, which increases the power of the gun.

Expanding springs are used in small models, while compression springs, on the contrary, are also more powerful. Double-spring - very strong, but difficult to charge.

The advantages of such products include simplicity of design, ease of operation, low cost and reliability.

Despite this, such guns are not advisable for beginners because they have:

- Weak lethal force;

- Low buoyancy;

- Noisy during reloading and shooting;

- Low shooting accuracy. The barrel is thrown upward.

Hydropneumatic underwater gun

A powerful, but structurally complex speargun for underwater hunting. In its production, only high-quality materials must be used, because it is very demanding.

The design of this device consists of:

- trunk;

- muzzle;

- Receiver;

- Pistons for separating the hydraulic and pneumatic cavities;

- The handles in which the trigger mechanism is located;

- Harpoon.

Hydropneumatic guns have some advantages. With their help, you can hunt even at night in reservoirs that are completely overgrown with reeds. In addition, such a device can be fired completely silently.

Parts and materials for their manufacture

It must be said right away that air guns have an overly complex design, so it’s better to stick with spring guns. This is the simplest and most affordable option for self-assembly. To assemble it, you will need the following elements:

- a metal barrel of suitable diameter with a wall thickness of approximately 1 mm;

- piston made of stainless steel;

- guide bushing (part of the piston);

- a powerful spring made of wire with a thickness of at least 1.5 mm;

- holder made of sheet brass;

- hook for harpoon line;

- a handle made of two symmetrical halves with a trigger mechanism, including a sear, a spring, a safety and a trigger;

- a harpoon with a diameter of 5 or 6 mm made of a steel rod of similar thickness.

.IRPP_ruby .ctaButton { background-color: inherit; margin-left: 10px; position: absolute; right: 0; top: 0; } .IRPP_ruby:after { content: ""; display: block; clear: both; }

Pneumatic gun

The gun is considered wasteless and operates on compressed air. The “Shark” underwater gun is one of the representatives of pneumatic guns. The presence of compressed air replaces the spring. The power of the shot is determined by the pumping. When firing, there is no release of compressed air; it will not leave the chamber.

The engaged trigger mechanism releases the harpoon from the couplings. The pressure created from the energy of the compressed air pushes the harpoon out of the barrel. Such devices can be recharged underwater.

Air guns have a wide variety of power, which directly depends on their size. Larger pneumatic devices are more powerful. Many systems have combat regulators. With their help, the force with which the harpoon will be allowed to fly out of the barrel is selected.

Pneumatic devices are produced mainly with 11-13 mm barrels, the thickness of the harpoons for them is 7-8 mm, respectively. 7 mm arrows fly out with high initial speed, but they are more likely to lose it due to the presence of less weight. Whereas 8 mm harpoons fly out with a low initial speed, but are capable of covering significant distances.

By the way, the Zelinka underwater gun is deservedly considered by many amateurs and underwater hunting professionals to be the best air gun in its class. Knowing the tactical and technical characteristics of this underwater weapon, experts recommend using sevens for hitting targets at short distances, and eights for hunting from a distance of several meters.

Some specialists will improve their devices by installing an additional pneumatic vacuum system on them. It will prevent the accumulation of water when loading in the barrel space. The underwater gun "Pelengas" is one of the representatives of pneumatic vacuum guns.

Advantages of air guns:

- Efficiency is high;

- Convenient use;

- High maneuverability;

- Good buoyancy;

- Considerable power;

- Adjustable stopping power;

- Compact sizes.

Disadvantages:

- Noisy shot;

- Big recoil up;

- The need to get used to the aiming process.

At the end of the spearfishing season, it is recommended to bleed the air from the chamber.

Underwater gun made of wood. DIY elastic crossbow (underwater gun)

Content

Today there are many guns available for underwater hunting. Their difference lies in the design. The most common of them are harpoon modifications. There are also traumatic models on the market that have high muzzle energy. If you assemble weapons for scuba diving yourself, it is more advisable to consider harpoon modifications. After all, a wide variety of materials can be used for them.

It must be taken into account that the destructive power of a homemade weapon depends on the parts used. To assemble the model yourself, you should consider the most popular devices.

Model of a shotgun with a double slide

First of all, you need to think about preparing the pipe. Its length should be at least 12 cm, thickness - approximately 4.4 cm. After grinding it, you need to make a channel.

- It is cut 0.5 cm wide. This is required to place the cleaning rod.

- Then the skid is attached. For it you need to select a wide piston.

- A hook can be used to secure the tube. A wooden frame will do here. Although you can stick an overlay on it.

- After this, you need to connect the sear to the gun. Only after this is it possible to install the mainspring. It should have a diameter of 3.5 cm.

For such models, winding is rarely used. The line with the trigger should be installed last.

Shotgun with metal blocks

A Hawaiian gun designed for spearfishing can be equipped with metal stocks. To do this, you need to prepare a pipe, the length of which is 12 cm. Its edges can be turned on any machine. After this, the pads are stuffed. From the front, they should be installed from the edge at a distance of 2 cm. At the rear, they should be attached 2 cm further. This is required to secure the barrel to the holder.

Underwater crossbow

This type of weapon for underwater hunting is used mainly in sea water and under conditions of good visibility. The design of the crossbow is very simple and reliable. Because of this and for several other reasons, the spearfishing crossbow is now extremely popular.

Crossbows with a length of 500-1500 mm are popular on sale. It should be remembered that it is not the actual length that is taken into account, but the distance from the first hook of the harpoon to the places where the rods are attached, that is, the barrel (“barrel”) is measured. The actual size will exceed the stated size by approximately thirty-five percent.

Main advantages:

- Accurate shooting;

- Silent shooting;

- Simple design;

- Insignificant price.

Flaws:

- Low rate of fire;

- Poor mobility.