PVC pipe is the most convenient option for constructing products with your own hands. These products are perfectly held together using glue or soldering.

Even if the boat gets damaged during use, there is no need to be upset. Such repairs on your own will not be difficult. Using the same glue, simply apply a patch to the damaged area.

To what has been said, it must be added that building such a boat with your own hands is a very interesting job.

It is recommended to start making a boat with the selection of a drawing. Based on them, the most convenient design is selected.

It’s a good idea to first make patterns of reduced sizes and glue such a structure from ordinary plastic bags. With this kind of work, you can “feel” the material, which means that working with full-scale sizes will be much easier.

After working out the patterns, they are increased proportionally. Craftsmen advise checking the compatibility of the workpieces by making the structure in natural dimensions from polyethylene.

This will, of course, take extra time, but it will be worth it. If any errors were made in the calculations, this will be clear at the initial stage, and there will be no need to spoil expensive materials.

DIY folding boat

Homemade plywood boat (master class, photo, step by step)

So we finally got around to realizing our old dream and started building a boat. For the first time I chose an easy project, so to speak for training. I went to the production of similar boats in Cherepovets and there I spied something and bought the missing materials, for which special thanks to the owner of the shipyard.

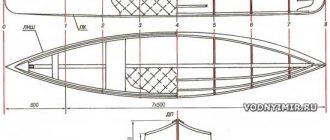

This is what the boat should look like:

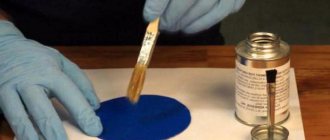

Today I cut out sheets of plywood and began the most important and difficult process, in my opinion, which is cutting and gluing sheets of plywood. Because If the length of the boat exceeds the length of standard sheets of plywood, then they have to be spliced; there are many ways to do this, but I chose the most technically complex, but also more aesthetic option of miter gluing.

We process the plywood sheets first with a plane and then with a sander.

This is what it looks like during processing.

This is how the sheets should fit and stick together.

After adjusting the parts, I glued them together and placed them under the press.

That's all the preparatory work on the boat for now; after the sheets are glued together, I'll start marking and cutting out the parts.

At first I practiced miter joints on scraps of plywood and it was scary to look at, but experience came from working on the “finish” version