Recommendations for choosing materials for the frame and awning

The basis of any tent is the frame. The reliability and stability of the structure and its service life depend on the choice of material. To make the frame, you can use several types of materials, depending on whether it will be stationary or collapsible:

- wood is the most affordable and environmentally friendly frame. Depending on the thickness of the timber or boards used for construction, you can build either a large tent or a lightweight portable structure for a large number of guests;

- Galvanized profile is an excellent material for a portable tent. Easily fits into a bag and is transported, will last quite a long time;

- polypropylene or metal tubes - easily installed using special connecting modules, depending on the diameter, can be used for the construction of tents of various sizes;

- brick - used for the construction of a stationary frame. Some construction skills will be required. Most often, this type of tent is used as a summer kitchen.

The collapsible design looks weightless due to the successful selection of awning material

In order to make your stay in a tent as comfortable as possible, mosquito nets, fire-resistant materials and convenient fasteners are used in the manufacture of tents.

A variety of materials can be used to make a tent awning. They are selected depending on the material from which the frame will be made:

- tarpaulin - not exposed to moisture, very durable and dense. Has significant weight compared to modern materials;

- polyester with polyvinyl chloride additives is a modern lightweight material that dries quickly, does not fade when exposed to sunlight, and is easy to clean. Has a limited color palette;

- acrylic is a material that can be painted in a variety of colors and does not change its qualities under the influence of weather conditions. Quite difficult to process;

The awning should be made of dense water-repellent fabric

- mosquito net, nylon - thin, translucent fabrics used to decorate the side walls of a tent or windows.

To decorate the side parts, you can use natural fabrics: linen, cotton, chintz - it all depends on the purpose of the design

Thick fabric is used for the dome, and the side walls of the tent are decorated with light fabric

DIY trailer awning

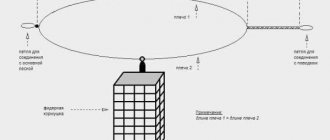

In order not to purchase excess material, you should know the exact size of the awning being created. Initially, for this it is necessary to prepare a frame, of course, if the car enthusiast has planned this particular option. The most popular type of frame system for passenger car trailers is the so-called “house”. Making it is quite simple - if a person has skills in welding - three elements are usually installed: in the center and on the front/rear side of the trailer.

The next step is taking measurements. To do this you will need:

- Measure the length and width of the trailer;

- Find out the dimensions of the vertical posts in the frame;

- Find out the distance from the highest point of the metal frame (ridge area) to the side.

After this, using the simplest mathematical calculations, known from the standard school course, the area of the entire tent and the dimensions of each of its parts are calculated. Naturally, it is advisable to use paper for the pattern, which will allow you to easily make changes and initially wait to purchase the material itself - to further save it.

When creating a cut, it is also very important not to forget to make seam allowances:

- On the lower part of the future awning for a passenger trailer - four centimeters each - there is a specially compacted place for installing metal rings;

- On other seams, two centimeters is enough.

For direct sewing you need to have:

- Actually, a sewing machine;

- Strong needle (120-130);

- Strong thread. It is advisable to take reinforced or polyester options.

It is recommended to attach the front and back parts of the “house” to the main surface of the awning using a double seam. Be sure to remember to seal the bottom of the material for subsequent installation of the rings.

Before the next stage, the awning is temporarily placed on the frame so that it is possible to accurately mark the locations for the eyelets. To install these elements you will need a special machine, which can be found in any good shoe workshop - you will have to carry the material there, and, unfortunately, pay a certain amount of money.

Before the final installation of the finished awning in its place of further use, a previously purchased rubber band is inserted into the eyelets. Fixing the product to the trailer itself is best done with a strong (at least eight millimeters) rope or cable (about three millimeters) made of metal.

Everything is ready - you can use the results of your own work!

How to sew a camping awning yourself

Today you can buy tourist tents of various shapes and sizes, but you can also sew them yourself. And the point is not that it will be half the price, but that you can sew an awning to suit your needs and make it exactly the way you need. Well, I just like to do everything myself, because the process itself is interesting. And today we will talk about how to sew a camping awning with your own hands.

The first thing you need to do is find the right fabric. In small towns this can be a serious problem. You don't often find travel fabrics in stores. I had a hard time finding green, as I was told, “tent fabric” without a name. Most likely it was an Oxford. Price 75 rub. per linear meter was more than attractive and I bought 8 meters. The width of the fabric is 1.5 meters. If you sew two pieces of 4 meters each, you will get an awning of 3x4 meters , which is what I need.

Please note that in stores the fabric is often not cut, but rather torn from the roll along the fibers. But the weaving of the threads in the cut does not correspond to the parallel-perpendicular axes of the roll. This way, the torn edge of the fabric will not be perpendicular to the side of the cut. And, if you need the exact geometry of the finished product, take at least half a meter of fabric to spare and cut it strictly at right angles.

I cut my piece of fabric in half. Along the edges there is a strip with punctures and deformation of the fabric, which remains during production. All this needs to be cut off, at least from those sides that will be sewn together in the middle of the awning. If the fabric has a front side, then we fold the two pieces face to face. The bottom layer should protrude 5-6 millimeters from the top.

We wrap these 5 millimeters up and stitch them on a typewriter.

Awning frame for a garden gazebo

The frame for an awning for a garden gazebo can be made of either wood or steel.

If you need to make an awning for a garden gazebo with your own hands, then its construction must begin by marking the area over which you need to stretch it. First you need to decide on the locations for the support posts of the future design. In these places you need to dig holes 50-70 cm deep. Racks are inserted into these holes, which will support the entire mounting structure. It is better to fill the holes in which the racks are installed with cement for strength, although you can do without filling by filling them with wet soil and compacting them thoroughly.

The installed racks, especially if they are secured with cement, should be left for 1-2 days, after which you can proceed to the installation of the crossbars. The racks at the top are connected by wooden or metal guides in a cross shape, and the guides should form a cross above the center of the future gazebo. Crossed guides should be secured with a fastening center. This could be a metal clamp, wire or even rope.

The roof of the tent made of polycarbonate is the strongest and most durable.

To make the structure more stable, the support posts at the top need to be connected with jumpers around the perimeter of the frame and secured. Now all that remains is to check the reliability of the fastenings, tighten them if necessary and pull the awning fabric over the finished frame.

The awning canvas can be made from polycarbonate sheets. In this case, the frame should be 10-15 cm smaller than the polycarbonate sheet being laid. For support posts of this design, it is better to use aluminum pipes. In this case, the guides are attached to the racks using angles and bolts. The polycarbonate is attached to the frame using self-tapping screws.

To install a wooden frame under an awning for a garden gazebo, you will need the following tools:

- bayonet shovel;

- hacksaw;

- hammer;

- screwdriver;

- wrench (when used as clamps for iron clamps).

To construct a metal frame you will need the following tools:

- bayonet shovel;

- grinder or metal file;

- welding machine;

- wrench (when used as clamps for iron clamps).

Methods of fastening the awning structure

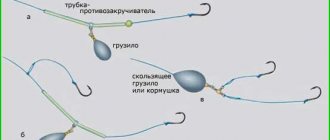

The material for the trailer awning provides several mounting options. The car owner can resort to the following methods:

- attach the manufactured structure to the main body using metal rings;

- create eyelets by placing them along the edges of the fabric;

- pull a cable or rope through the rings located above the general structure.

The lugs must be removed by 200 mm, in addition, all rings must be equipped with fasteners.

Cable and rope can be used as a fastening element. Regardless of the method of fastening, the retaining element must consist of a single piece, the edges of which are reinforced with metal tips. When securing the awning, the retaining device must pass through the rings and be tightly stretched.

Introduction

It is no secret that an awning for a passenger trailer, made from high-quality modern material, has characteristics such as durability and good resistance to any temperature. Careful, and most importantly, correct operation helps extend the life of such coating up to 15 years. After the expiration date, more precisely, 10–12 years, signs of wear appear on the fabric, which are manifested by a lack of former elasticity and strength. It is worth noting that it is very difficult to buy a factory awning that could ideally fit under the frame of your own trailer. In order to purchase the “correct” awning that will fully satisfy all the owner’s requirements, one should take into account the fact that the areas where the fabric comes into contact with the metal rods of the frame must be additionally sealed, which will allow for a tighter fit. No manufacturer of standard coatings will be able to correctly calculate the distance between the posts without measuring the specific trailer. In such a situation, there is only one true solution - to make an awning for the trailer yourself.