What is it needed for?

An awning is a multifunctional device: the tasks assigned to it depend on the specific type. Most often it is needed to perform the following basic functions:

- Protection of things loaded into the boat from moisture, since a lot of splashes occur when it moves.

- Protection of boat passengers from precipitation or direct sunlight.

- Ensuring a comfortable overnight stay on the boat.

Types of boat awnings

As already mentioned, there are a number of varieties of such devices that determine their functionality. They are usually classified as follows:

- A transport cover is necessary to provide protection for the boat during transport when there are no passengers in it. This is due to the tight fit of the boat, so a limited number of things can be placed in it, but they are completely protected from weather conditions. This type can be used when the watercraft is in a car trailer or when it is manually moved along the coastline.

- Walking awning is an equally popular and necessary variety, which serves to provide comfort and protection for passengers during the operation of the watercraft. It is usually used if you plan to spend a long time on a boat, so this device is most relevant when fishing or spending the night on the water.

Modern models are equipped with zippers that allow you to create a small tent that provides reliable protection not only from weather conditions and water splashes, but also from insects.Such a device is absolutely safe, since even with strong gusts of wind, the width of the boat does not allow it to turn over, but sometimes there is a risk of the awning being torn off, after which it can be carried away in the direction of the wind. There are modifications and simpler models, which are a roof made of PVC, located horizontally relative to the frame and without side walls.

Chassis

Transport

Nasal

Parking - Bow awnings used to protect passengers from strong gusts of wind or splashes of water that occur when the boat is moving. The device fits onto the nose, creating a structure that resembles a car windshield.

It must be taken into account that all such models increase the sail performance of the boat, due to the creation of a certain resistance to the oncoming flow.However, if you have enough experience in operating boats or have a motor, this is not a big problem.

- Parking awnings are relevant for long-term storage of watercraft in outdoor conditions. They provide protection from the negative effects of weather conditions both on the boat itself and on the items loaded into it.

Awnings for PVC boats in Moscow

Among the huge range of products on our website, PVC boat awnings are especially popular. These are safe devices that can be ordered in Moscow at manufacturer prices. Reliable models of PVC boat awnings are sold at retail. The conditions for wholesale purchases are discussed individually.

Powerful technology at an affordable price

On our website, accessories for boats are presented in a wide range of prices; these are not only expensive solutions, but also budget analogues. The PVC boat awning models are characterized by the following characteristics:

- minimum fuel consumption;

- safe design;

- convenient operation;

- high reliability;

- Manufacturer's warranty up to 2 years.

Thanks to their small dimensions, PVC boat awnings easily fit in the trunk of a car. They won't take up much space in your garage or shed. They will become an excellent assistant for several hours of continuous use. Effective and safe accessories for boats are an excellent choice for active outdoor activities (hunting, fishing, tourism), work (patrolling territories) and economic activities. For the convenience of customers, our website contains all the popular accessories for boats in Moscow. Each item is described in detail, real photographs and prices are offered. You can select the equipment yourself or use the help of our consultants. If necessary, they will help you compare several models you like or clarify questions regarding technical characteristics, purchase/sale and delivery in Moscow.

Motomarine - a store for lovers of quality goods

The site presents PVC boat awnings, which are distinguished by high reliability.

To order the unit you like, fill out an application on the website or contact our consultants. These are experienced employees who will help you decide on a purchase or simply tell you about the features of using PVC boat awnings. In addition to free consulting assistance, we offer:

- Favorable prices from the manufacturer.

- Regular updating and replenishment of the catalog.

- Promotions, sales and discounts on popular towing vehicles.

- Beneficial cooperation for retail and wholesale buyers.

- Manufacturer's warranty.

With our help, it is very easy to buy safe accessories for boats. PVC boat awnings in Moscow. Call or leave your number in the feedback form if you have any questions or suggestions for cooperation.

Preparatory stage: what to consider

Before starting, it is necessary to carry out the following preparatory activities:

- Initially, the boat is brought into fully working condition , since not only its dimensions are taken into account, but also the features of its geometric shape.

- Particular attention should be paid to all additional devices on board, as well as the motor and the characteristics of the cylinder.

- All information received is transferred to paper, since the drawing will allow you to get a visual representation of what the awning will look like. Here it is also necessary to take into account your own experience, since in the absence of it it is recommended to start with the simplest options to hone your skills.

- If you have no experience, it is recommended to apply marks not on the material, but to first prepare a pattern . For these purposes, you can use plastic film, fabric or other types of materials that are suitable in size.

- At the final stage of the preparatory work, the pattern is correlated with the working material, onto which all the marks are carefully transferred.

Instructions for making a frame

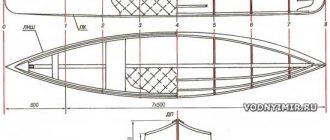

Another important stage is the manufacture of the frame, which can be started even before choosing the base material. Typically, this design is shaped like the letter “P” or an arc.

Detailed instructions are given below:

- Particular attention is paid to the choice of material for the frame ; the main requirement is its lightness, since PVC swimming equipment often cannot withstand heavy structures. For this reason, the ideal solution would be pipes made of aluminum with a diameter of 1.5 to 3 cm. You should also check the wall thickness of the selected pipes: if they are too thin, the risk of breakage increases when trying to bend the structure.

- The arc must rest on its fastenings; contacts with other parts of the craft must be excluded in order to eliminate the risk of damage during operation.

The height and dimensions of the frame are directly dependent on the design features of the craft. It is necessary not to make mistakes in the calculations; for this, a person takes the position of the helmsman, after which the frame tilts in turn in each direction. Its height should be adjusted until the dead zone in front of the boat reaches 6-7 meters.

- To change the shape of aluminum pipes, you can seek help from specialists from a metalworking workshop, but many people prefer to carry out such manipulations manually. Here you will need to be careful and attentive, since all sections of the frame must be level, and the pipes are not allowed to go beyond the plane within their section.

- After bending the pipes, you should check them by placing them on absolutely flat surfaces. The complete fit of the entire structure indicates that the technology was followed. If there are visible gaps or gaps, further work will need to be done to align the pipes.

- The next step is the installation of supports for this structure . For these purposes, the fittings of the boat are used, but sometimes there are models whose design does not provide for the presence of additional holes. In such a situation, you will need to contact a specialized store to purchase fasteners and elements. Their installation provides some advantages, since it will be possible to independently determine the location of the units and the angle of installation of the awning, depending on individual preferences.

- The arc is fastened using bolts ; their diameter usually varies from 0.6 to 0.8 mm. The choice depends primarily on the angle of inclination and the selected diameter of the aluminum pipes.

- The pipes are pre-grinded , which makes their surface as smooth as possible. During the installation process, it is necessary to ensure that the frame does not have direct contact with the boat cylinder.

Making tents for fishing with your own hands

To save money on buying an awning, you can make it yourself. To do this, you can use ready-made drawings or design it yourself, taking into account the dimensions of your existing boat.

Before manufacturing, you need to measure the dimensions of the boat, taking into account the shape of the bow and the presence of protruding fittings.

Walking awning

Frame making

Frame

The frame is the basis of the awning. You can make it yourself from aluminum pipes. The best option is to use a pipe with a telescopic connection.

For a horizontal running frame, it is enough to use thick-walled aluminum pipes with a diameter of 15-30 mm. Even a folding bed frame will do, but a more acceptable option is a base with a sliding joint. You can make a frame from thick plastic wire, plastic or metal-plastic pipes.

Most often, the base of the roof is made of pipes bent in the shape of the letter U or of arcs. You can bend the pipes yourself using a special pipe bender or contact a mechanic who has the tools to do this work. The edges of the pipes must be cleaned so that there are no burrs left that could injure you or damage the base of the boat.

Next, we lay out the bent frame on a flat surface and check the accuracy of the bend of the finished products; if there is an error, we correct it.

We make the supports for mounting the frame ourselves or purchase them in the store. You can use elements of the railing system.

The finished frame is tested for strength, after which we move on to the next stage of manufacturing.

Materials for making an awning

Most often used for making awnings:

- synthetic nylon fabric,

- rough, airtight material made of fabric impregnated with polyvinyl chloride;

- tarpaulin is a strong material, but it gets wet from splashes. Fabric is produced with impregnation, which has the ability to repel moisture.

For visibility in walking awnings, the use of viewing windows is required. Materials based on:

- transparent lavsan;

- dense polyethylene;

- transparent PVC film, which is not recommended for use for complete or greater coverage of the vessel, since it does not allow air to pass through.

The most optimal material for the manufacture of a roof awning is a synthetic fabric made from nylon or other materials that are sufficiently durable, resistant to moisture and atmospheric influences.

Pattern

The material should cover the main part of the boat; it is folded at the locations of the cylinders. For a small boat, it is enough to buy material 1500 mm wide and 3500-4000 mm long. If you do not have sufficient cutting and sewing skills, it is better to purchase the material with a reserve.

Read the Fishing Report on Lake Velje

To sew an awning you will need:

- textile;

- wide elastic band and rubber cord (rope);

- rings and hooks made of plastic;

- eyelets;

- dense thread and thick needle.

- waterproof glue for processing firmware joints.

First we make patterns from any old material or polyethylene, do not forget to make allowances of 2-3 cm at the edges for sewing a through sleeve into which we will thread a rope or rubber cord.

It is not advisable to use high-quality material for the pattern right away, since if you cut it incorrectly you can ruin it; it is better to make a preliminary template.

Bow awning

The easiest awning to make is one that covers only the bow of the boat. It protects people and equipment from oncoming splashes and from getting wet. At the same time, you can hide under it from the scorching sun or rain.

The awning for the bow of a boat is made in two ways:

- on a frame;

- stretching the fabric over the bow of the ship.

For high-quality stretching of the fabric, carabiners are used, attached to elements of boat fittings. If there are insufficient number of grooves for attaching the cover to the swimming craft, additional eyelets are installed independently.

The upper part of the structure is attached to the transport units.

Transport or parking awning

It is used for ready-to-use boats with motors pre-mounted on board. This fact gives grounds for a thoughtful design of a cover with protection against damage to the motor unit. In the motor part, to create a cover, you can use shock-absorbing material to protect against minor damage. This type of awning should not have a complex fastening design, since when removing it from the boat it should not take a lot of time to dismantle it.+

The manufacture and subsequent use of an awning will extend the service life of your boat much longer.

Self-production

Necessary materials

One of the most crucial moments is the manufacture of the awning itself. However, before moving on to it, you should make sure that you have all the necessary materials:

- The main material, length and width of the canvas must be at least 4x1.5 m.

- Mounting thread 320 made of synthetic materials.

- A set of special needles that are suitable for working with such threads.

- Eyelets designed to strengthen edges.

- Half rings.

- Hooks made of plastic.

- Textile slings.

- Elastic bands with a fairly wide width.

Instructions

After all the preparations, you can proceed directly to the manufacturing process; detailed instructions are given below:

- The canvas should be cut in accordance with previously made measurements.

You should not forget to take into account the throughput sleeve and maintain a small allowance. Later it will be useful for installing the rubber cord. - Now you need to make loops that will be attached to the nose eye-handle. The features of the loops are determined during the manufacturing process of the awning and depend on the selected variety and its purpose.

- Eyelets are mounted on the edges of the hinges, which will allow them to perform their main functions.

- Holes are made in the throughput sleeve.

- Slings are fixed and securely fastened along the edges of the material used; they are necessary to strengthen the fabric.

- At this point, the production of the bow awning can be completed. However, if it is necessary to obtain a running version, then additional fasteners are mounted in the central part of the awning.

- When pulling the resulting awning, it is necessary to use carabiners that are attached directly to the fittings of the boat. This will ensure reliable fixation of its position and fasteners. Additionally, you should check that the sail edges are securely attached to the boat.

How to make a walking awning

The organizational stages of manufacturing this type are similar to the bow one: we determine the dimensions of the boat, the frame, and make a pattern for the awning using test material.

The following materials will be required:

- a pipe for an arc measuring at least 20 mm (at least 4 m);

- bracket (at least 9 pcs);

- awning fabric (not less than 9 m);

- nylon threads;

- transparent film for window parts;

- fasteners for fastening parts of the awning when folding them (at least 10 pcs);

- buttons for fastening the awning.

Manufacturing and installation:

- To begin with, a frame is made: one pipe will be the carrier (large size), and the second will be mounted on the middle part of the carrier (small size).

- Manufacturing occurs by bending aluminum pipes to obtain the desired shape, taking into account the dimensions of the boat and the expected ceiling height of the future awning.

- Having prepared the desired shape of the arc and retreating at least 20 cm from the base of the tube, a device - a clamp, with holes for bolts - is placed in the middle of the supporting frame.

- The small frame is equipped at the ends with a fastening device with a coupling to limit its rotation in one direction. With these fasteners, parts of the frame are fixed to each other with bolts. Here you need to take into account that the limiter in the fastener is located on the outside of the small frame, from the supporting one.

- Having previously installed the frame on the desired part of the boat, marks are made to place the fastening spots.

- The parts of the boat where the marks were made are cleaned and covered with glue. In the same way, the patches are covered and glued.

- The upper edges of the frames must be equipped with clamps-rails, into which rubber shock-absorber belts will be attached, equipped with hooks that will be attached to the front and rear parts of the boat cylinder in fastening fittings.

- After installing and fixing the frames in a vertical position, as a rule, the entire structure of the running awning will be placed on them. After manufacturing and installing the frame, you will need to cut out the elements of the awning. They consist of several parts, including transparent oilcloth parts for front and side viewing.

- In manufacturing and cutting, the lower parts of the side and front elements must have a spare length of up to 20 cm, where they will be folded to the inside, thereby forming a passage for the rope. The folded part must be equipped with holes for eyelets with a distance of up to 15 cm.

- The side, viewing and overlapping parts of the awning must be stitched with zippers from the inside in order to combine with other elements of the awning and the frame.

- At the end parts of the awning, where the zippers are sewn, it is necessary to attach push-button attachments to tightly fix the parts of the awning and prevent the zippers from opening when exposed to wind.

- After making and cutting the awning, the first step is to attach the ceiling part of the awning to the frame arches. The top of the awning is stitched with three zippers. One zipper is sewn on the inside, one on the edge of the awning and one on the outer middle part between the inner and outer zippers. Here you need to take into account how the zipper wraps around the upper arc of the frame.

- The awning is pulled onto the frame by attaching the outer and inner zippers to each other, taking into account the coverage of the frame arc.

- An external zipper is used to secure the viewing and side parts together.

- Arches must be made in two sizes. Small arc for the front of the boat, large arc for the middle of the boat.

- When in use, the awning must be in a well-tensioned state. To do this, shock absorber cords are placed at the edges of the side and rear parts of the boat. At the ends of the cords there should be hooks attached to the eyelets and pads.

- Next, having installed all the elements of the awning, you need to pass the rope along its lower part, where a passage is sewn for the rope, through which it will be attached to the side fittings of the boat cylinder.

Read Zander bite

Note:

- Particular importance is attached to the availability of the ability to tilt the awning, by pulling it in the viewing part of the boat and jumping off the eyelets from the mounting screws, this ensures the adoption of prompt actions in appropriate situations;

- When forming the side viewing parts, choosing denser materials, you need to make them in small sizes, or assemble them from parts with a hinge, for convenient folding.

Rules of operation and care

The service life will primarily depend on compliance with the basic rules of use and care, which are given below:

- Any contamination must be promptly removed from the surface of the awning . To do this, you should use sponges or brushes, but they must have soft bristles so as not to cause damage.

- The process of washing the awning is carried out using a hose , but it is not allowed to use too much water pressure, as this can damage the device.

- During the washing process, it is strictly forbidden to use any products containing chlorine , since they negatively affect the condition and service life of the PVC material.

- It is prohibited to transport a boat with a running awning ; special types should be used for these purposes.

- It is necessary to follow the rules for transporting the running or bow awning ; for this, it is packed in a reliable case that protects it from possible damage.

- Storing a dirty or wet awning is not allowed ; it must first be brought into proper condition. It is recommended to lubricate buttons or zippers with wax for preventive purposes.

- When folding the awning for storage, you need to make sure that no creases or folds form in any area.

- Storage is carried out only in rooms with normal humidity levels.

- When operating at too low or high temperatures, the mechanical impact on it should be minimized.

- Operation of any variety is allowed only at temperatures above 0°C.

- When used for overnight stays on a boat, it is strictly prohibited to use any heating devices.

- When using a walking awning, it is necessary to ensure ventilation of all internal spaces.

Tips and tricks

To summarize, we can give the following tips and recommendations that will be useful to people who decide to make their own awning for a boat:

- If you have no experience, it is recommended to first practice on unnecessary fabrics so as not to spoil the main material due to improper cutting.

- For the manufacture of the frame, it is necessary to use only high-quality pipes that are free of any mechanical damage.

- It is recommended to equip the running awning with zippers and a viewing window, which will make its operation as convenient as possible.

- Equipping the awning with additional pockets can significantly increase its functionality.

DIY making

First you need to conduct a visual inspection of the boat, after inflating it.

To identify design features, you need to pay attention to the following:

- The shape of the boat, as well as its dimensions.

- Examine the cylinders very carefully around the entire perimeter and highlight worn areas.

- Check whether auxiliary fittings are installed.

Based on these criteria, come up with a design for the frame and future awning. It is better to display all your ideas and measurements on an improvised plan.

It is worth noting here that measurements of the awning must be carried out very accurately, without any errors, otherwise you can simply ruin the material.

But to do this, you first need to design and install the frame, and only after that take measurements for the awning.

Installing a frame under the awning

Since the inflatable boat is not designed to carry very heavy weight, the frame should not be very heavy. Aluminum pipes are best suited for this. Diameter no more than 30mm.

Read Figure Eight Knot how to knit

So, let's start making:

- Most often, the frame is made in a U-shape. And if it’s easy to measure the width of the future frame, then what about the height? Everything is very simple. You need to take the place of the helmsman and tilt the pipe until the dead zone reaches seven meters.

- Now, knowing the required dimensions, the pipes need to be bent. To do this, it is best to contact a locksmith, where he will do everything professionally in his workshop. And if the master did everything correctly, then by placing the arched pipes on a flat surface, they will fit tightly.

- After this, you can begin fixing the frame to the boat. Typically, a fastening system is provided on the boat for such purposes. But if the boat is not equipped with such fasteners, then they can be bought at a specialized store and installed manually.

Materials and tools

If in the case of the frame we needed aluminum pipes and mounting holders, then to make the awning we will need the following:

- special water-repellent fabric;

- wide elastic band;

- plastic hooks and half rings;

- rubber cord;

- eyelets;

- thick needle;

Now you can start cutting and sewing.

Step-by-step guide to making different types

Before you start cutting, you need to take the necessary measurements.

Now the fun begins:

- According to the given dimensions, you need to cut the material with a small allowance, taking into account the throughput sleeve. It is needed to pass a rubber cord through it for fastening.

- Next, depending on the type of awning, loops are made, the edges of which will later be attached to the eye-handle. To do this, eyelets are first installed at the edges of the loops.

- To make everything more convenient, holes are made in advance in the throughput sleeve.

- To strengthen the material along the edges, additional slings are glued onto it.

This option is perfect for a nasal design. If the presence of a running awning is assumed, then the material is equipped with additional fasteners not only at the edges, but also in the central part.

To properly tension the awning, you need to use carabiners that are attached to the boat fittings. The cleat must be tightened and securely attached to the boat.

https://youtube.com/watch?v=IDNCh-Yn_-w

You may also be interested in installing a water jet on a boat yourself.